- Stock: In Stock

- Product code: 00-00012976

- Shipping Weight: 1,920.00kg

Available Options

Buy in Ukraine metal 3D printer FastForm FF-420q

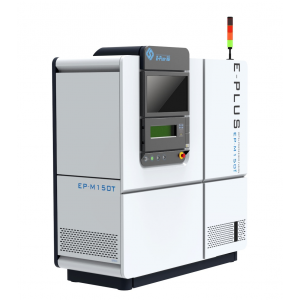

On this page you can buy FastForm FF-420q – industrial 3D printer that prints with metal. The material for printing is powder materials – metal alloys. Using powerful integration with 4 laser modules, the printer quickly and efficiently creates metal products of high precision and complex shape. And this happens in a matter of hours!

The printer operates on SLM technology – selective laser melting in a powder layer. This is a great way to create metal parts of any shape, in a working space of 420*380*300 mm for your industrial, craft, dental or medical production.

3D printer FastForm FF-420q – powerful industrial metal printer that supplies parts for a wide range of applications.

Key Features

- Working area size – 420*380*300 mm

- Number of lasers – 4 (optional 6 or 8)

- Multi-galvanometer

- Efficient printing

- Fast production

Why choose FastForm FF-420q?

- Efficient industrial printing.

- With 4 high-power laser sources at once, the printing speed has increased more than 4 times.

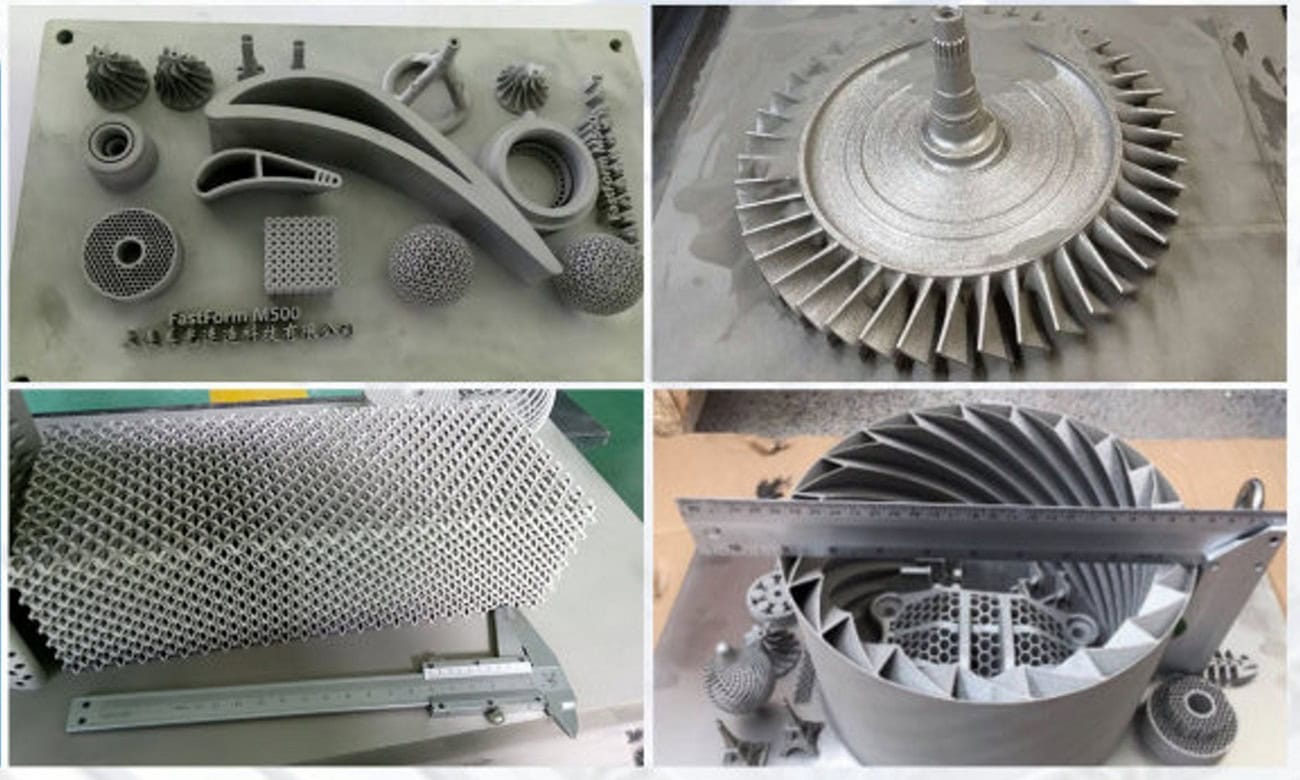

- Large print volume.

- 420*380*300 mm, which significantly increases productivity.

- Precision accuracy.

- Scanlab galvanometer provides high accuracy and low drift, ensuring flawless results.

- Wide range of materials.

- Compatible with various metal powders, including CoCr and titanium.

- Intuitive software.

- FastLayer and FastFab offer an easy-to-use interface and automated workflows.

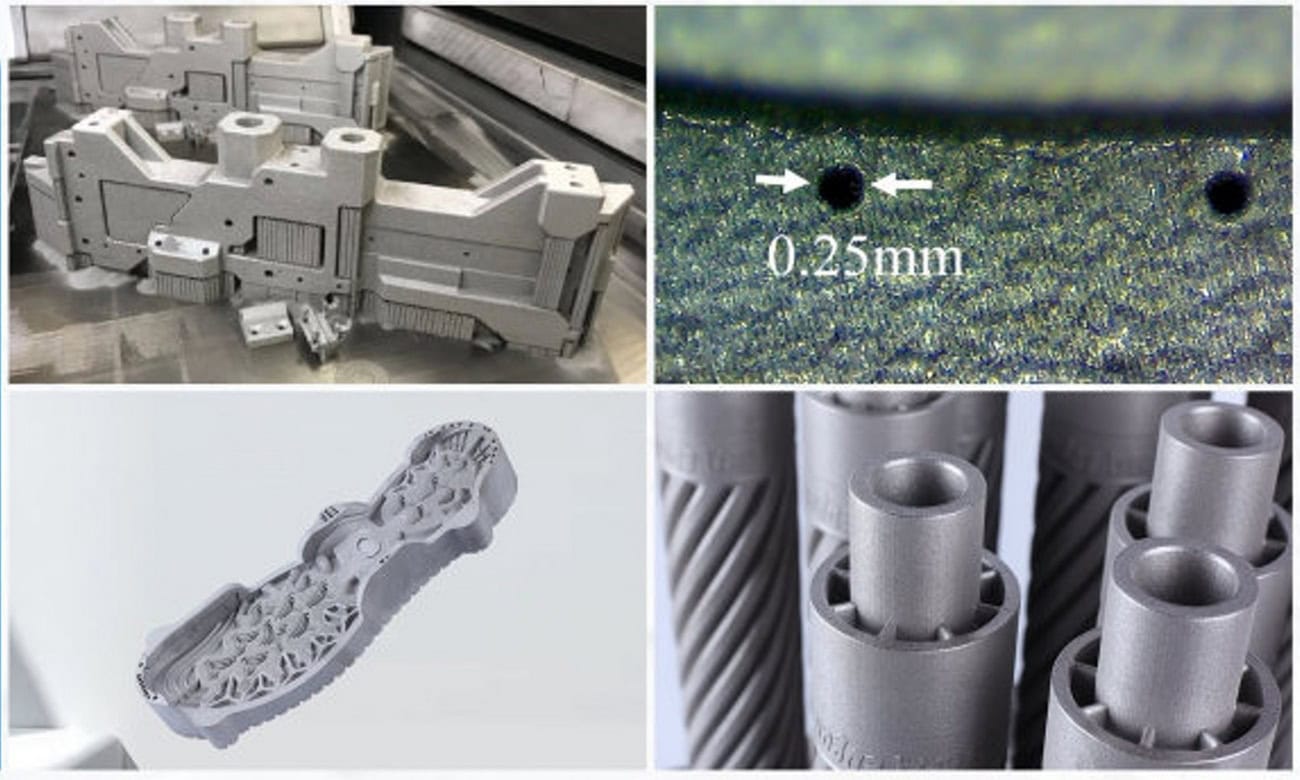

- High quality printed parts.

- Laser powder fusion ensures strong and durable products.

- Reliability and durability.

- Built with high-quality components for long-lasting operation.

- Ease of use.

- Intuitive interface and automation of actions minimize the need for operator intervention.

Metals for 3D printing on FF-420q

- Cobalt-chrome

- Titanium

- Aluminum alloy

- Stainless steel

- Nickel alloy

- Tool steel

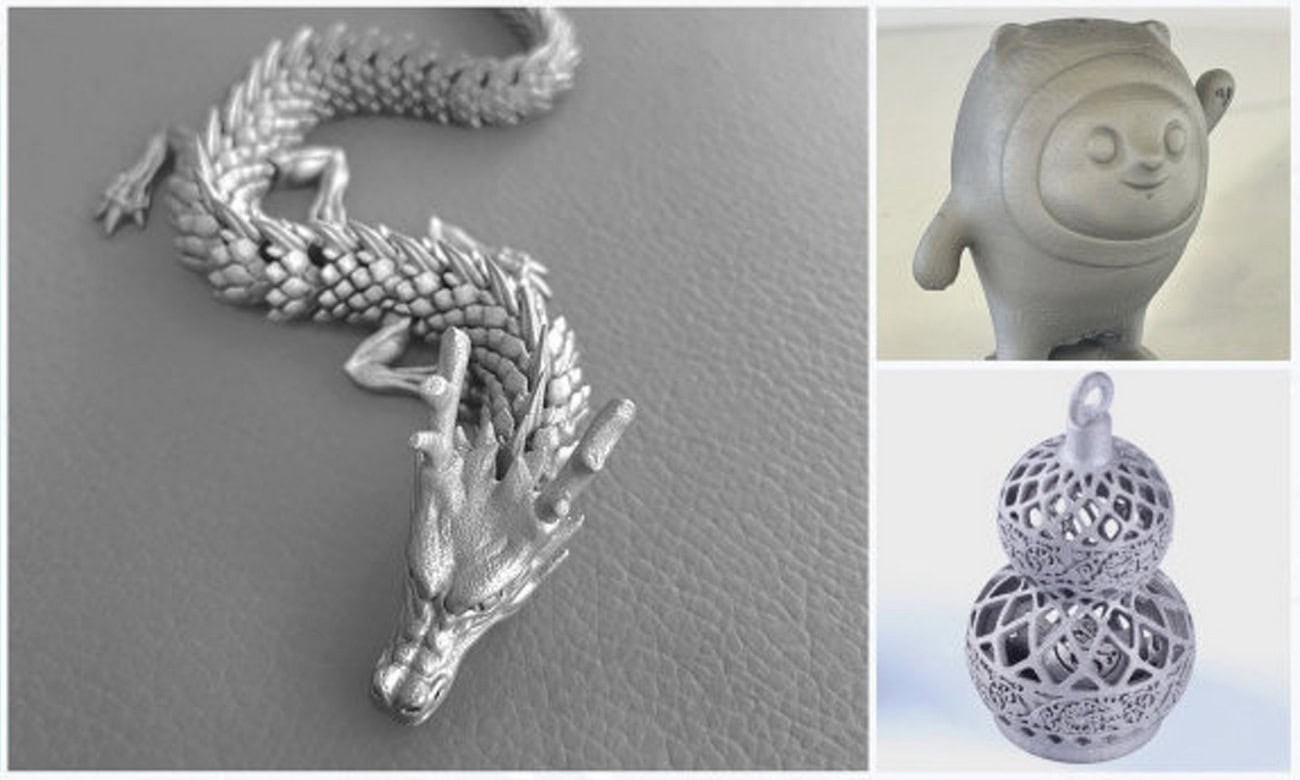

Applications of direct metal printing

Dentistry, medicine, prosthetics, industrial printing (molds, molds, spare parts, tools, fixtures), craft and jewelry, automotive and aerospace industries.

Auxiliary equipment

Supplementary equipment (purchased separately):

- Nitrogen generator

- Vacuum cleaner

- Sieving machine

- Powder drying oven

- Heat treatment furnace

- Sawing machine

- Explosion-proof vacuum cleaner

- Vacuum oven for heat treatment

- Sand blasting machine

After-sales service

- 24/7 English language remote service

- On-site assistance

Fastform FF-420q specification

| Printer Options | |

|---|---|

| Printing Technology | SLM |

| Build Field (mm) | 420*380*300 |

| Layer Height (micron) | 20 – 150 |

| Laser Spot Size (mm) | 0.05 – 0.02 |

| Printing Accuracy (µm) | 50 |

| Maximum Scan Speed (mm/s) | 10 000 |

| Production Capacity | 2000 pieces/Year |

| Laser Characteristics | 500W, 4 laser (6 or 8 lasers optional) Fiber laser |

| Gas Supply | Ar / N₂ |

| Oxygen Content | ≤ 0,1% |

| Supported Materials | Cobalt-chrome, Titanium, Aluminum alloy, Stainless steel, Nickel alloy, Tool steel |

| Cooling System | Water cooling |

| Features | Resume printing after power failure, Automatic power off, Top powder feed |

| Supported File Types | STEP, IGES, SLC, CLI, STL |

| Operating System | Windows 10 |

| Software | Fastlayer, FastFab |

| Connectivity | WiFi |

| Power Requirements | Three-phase 380V, max 15 kW |

| Air Handling | Permanent filter, service life of at least 30,000 hours |

| Manufacturer Country | China |

| Warranty Period (months) | 12 |

| Certifications | CE |

| Weight & Dimensions | |

| Weight Netto (kg) | 1600 |

Industrial metal 3D printer in Ukraine. Direct 3D metal printing

Do you have questions about the printer? Contact us today to get advice and learn more about the FastForm FF-420q.

Auxiliary equipment*

For a complete and safe metal 3D printing workflow, you may need additional equipment. We offer a wide range of accessories for FastForm 3D printers.

📌 For more information and assistance in choosing equipment, please contact your manager.

*Not included in the price of the printer.