Description

Markforged Onyx Pro Engineering 3D Printer

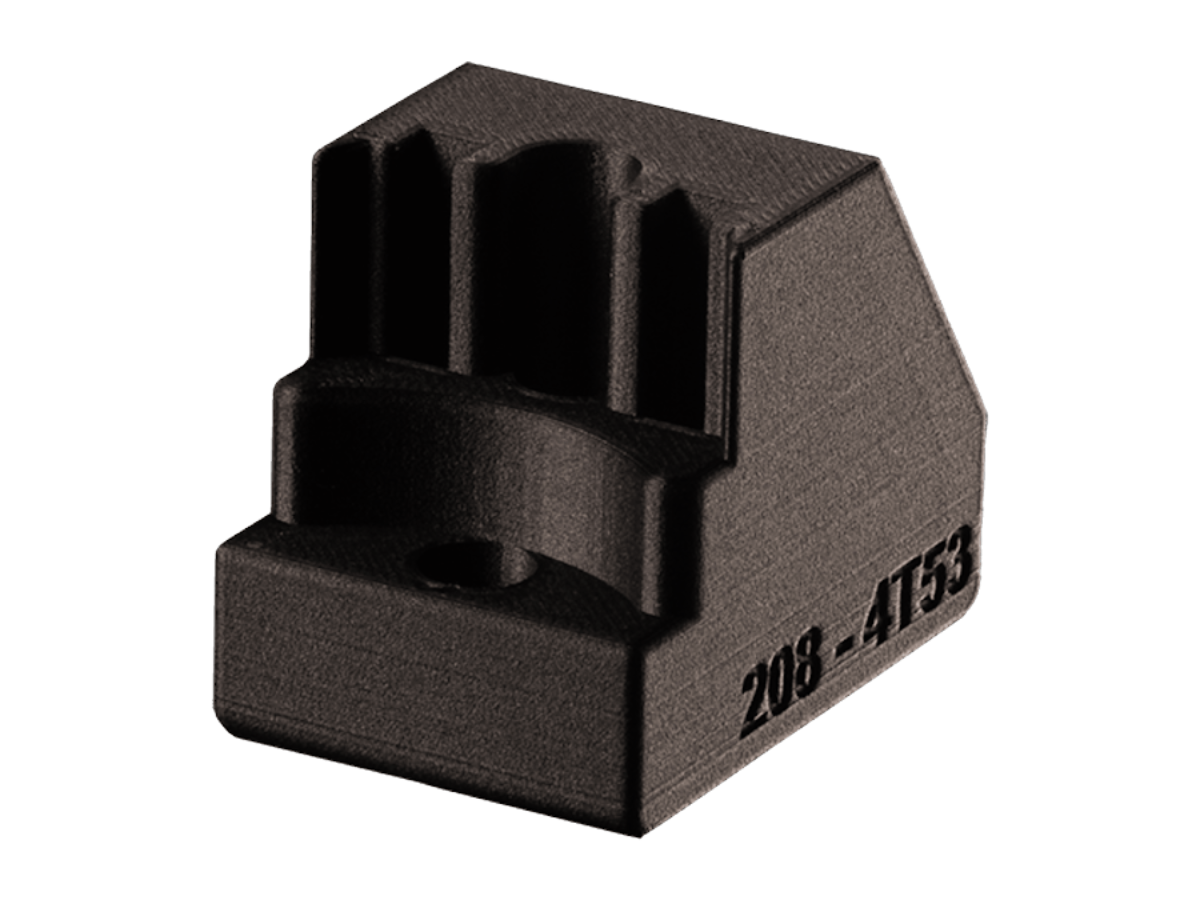

The Markforged Onyx Pro Engineering 3D Printer with 2 desktop heads will help you work more productively, quickly implement developments, and introduce optimized solutions. A professional printer for printing products from fiberglass-reinforced plastic.

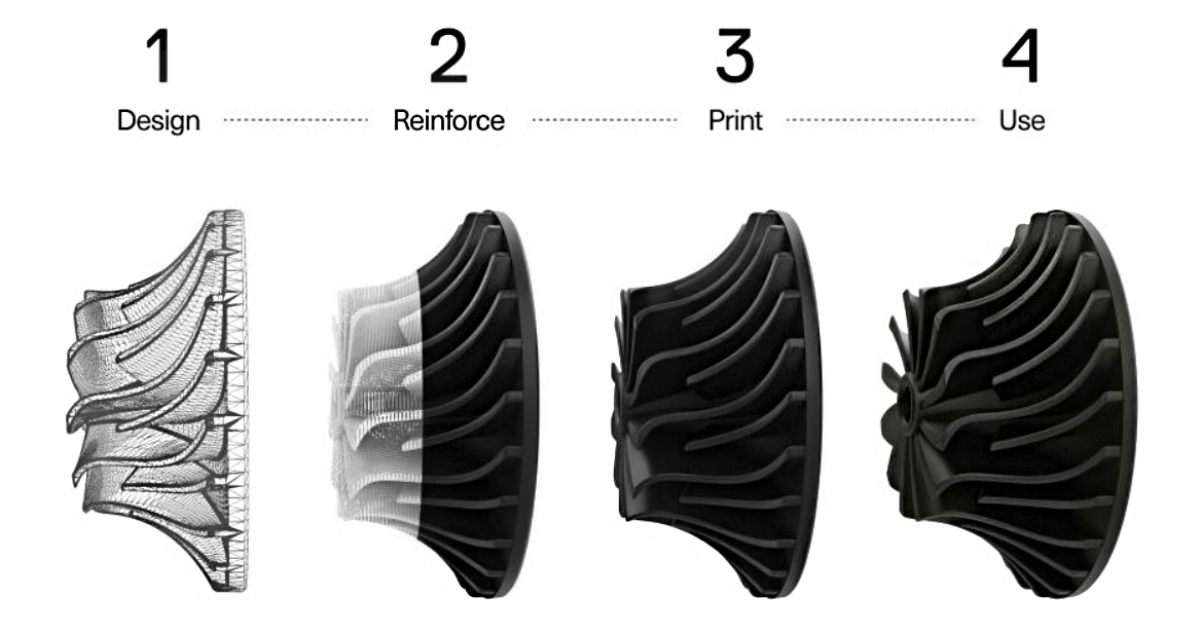

Continuous fiberglass printing is an important improvement for engineers

For productive work, the manufacturer has provided 2 heads. One is designed for printing with plastic, the second provides a continuous supply of fiberglass. This allows you to significantly enhance the mechanical characteristics of the finished product. The Onyx Pro engineering 3D printer demonstrates excellent mechanical strength. The device can be used in industrial production.

The second print head is designed for printing with fiberglass. The composite is added throughout the printing process, ensuring uniform product characteristics. The Markforged Onyx Pro 3D printer is designed for engineers, and they appreciate it: the printer is very popular in the engineering environment.

Convenience and functionality of the Markforged Onyx Pro 3D printer

Two nozzles in the printer complement each other. One nozzle is designed for printing with plastic, the second, reinforced – with fiberglass. Modern extruders are equipped with a system for detecting the absence of plastic. Markforged Onyx Pro operates on a solid aluminum frame, which contributes to high printing accuracy. The printing table is made of composite material, has excellent adhesive properties, is large and durable.

Features of printing of the engineering 3D printer Onyx Pro

The printing area of the Onyx Pro 3D printer is 320x152x154 mm. The thickness of the printing layer is 100 to 250 microns. The printer prints with closed cells. It is possible to choose the geometry of the printing cells. The main printing material can be selected from several options: Onyx, precise PLA, smooth TPU. With innovative materials and the latest printing technologies, the desktop printer delivers industrial quality finished products.

Eiger – always up-to-date software that is constantly being improved

Innovative Eiger software is the key to producing high-quality 3D printed components. Process automation, cloud integration and constant updates make Eiger the ideal solution for industry. The ease of use of the Markforged Onyx Pro engineering 3D printer and its powerful functionality allow you to focus on creating unique products. Thanks to its cloud location, the program updates itself. If the 3D printer is constantly connected to the Internet, you will always have the latest updates.

Technical specifications:

| Printing Technology | Nylon FFF |

| Build Field (mm) | 320*132*154 mm |

| Ø Of Plastic (mm) | 1,75 |

| Number Of Extruders | 2 |

| Chamber Type | Closed |

| Heating The Chamber | Yes |

| Autocalibration | Yes |

| Feeder Type | Direct |

| Layer Height (micron) | 100 – 200 |

| Extruder Construction Type | Second generation extruder, detection of plastic absence |

| Leveling System | Automated Bed Leveling, Adaptive Bed Leveling |

| Maximum Chamber Temperature (°C) | 60 |

| Automatic Filament Switching | Yes |

| Platform Heating | Heating, automatic alignment, replaceable printing sheets |

| Platform Material | Precision Machined Aluminum |

| Internal Part Geometry | Nylon Onyx: Closed Cell or Solid Infill |

| Supported Materials | Onyx |

| Features | Precision design FFF filament fusion printing Filling: solid or closed cells |

| Software | Eiger Cloud |

| Connectivity | Wi-Fi, Ethernet |

| Power Requirements | 100–240 VAC, 150 W (2 A peak) |

| Manufacturer Country | USA |

| Weight Netto (kg) | 15 |

| Dimensions Netto (mm) | 584 x 330 x 355 |

Reviews

There are no reviews yet.