Description

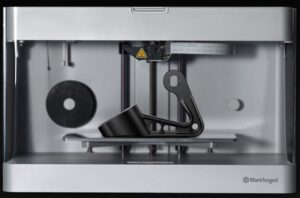

Markforged Mark Two Aluminum 3D Printer – Innovations at Work

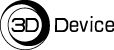

The Markforged Mark Two aluminum 3D printer prints carbon fiber parts directly on the desktop. Compact, reliable 3D printer with new generation extruders, with filament presence indicator. Thanks to composite materials, you can very quickly get industrial-quality parts with amazing strength, hardness and durability.

The Markforged Mark Two aluminum 3D printer is a device created for long and productive work

High-quality equipment, a solid aluminum body, precision design – the printer will work for you as long as necessary. Professional-grade printer, made on the basis of a solid aluminum frame. The stability of the design ensures the accuracy and reliability of printing using carbon fiber-based composite materials.

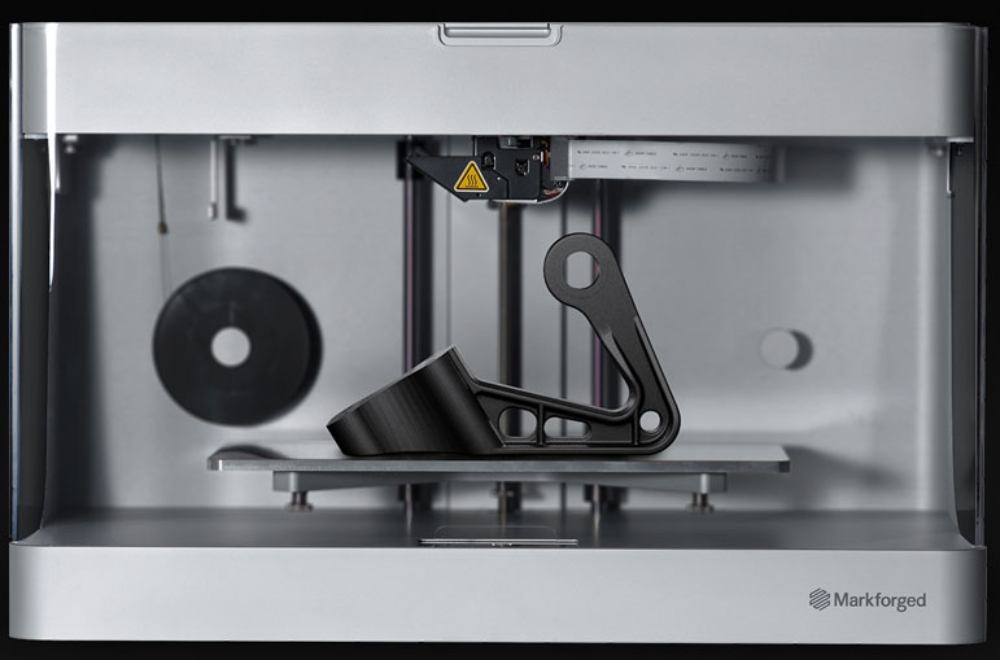

Innovative extruder – the key to print quality and durability of the Mark Two 3D printer

The extrusion system of the Markforged Mark Two 3D printer allows you to print with composite materials constantly. The parts involved are structurally prepared for such loads. The device is easy to maintain, the most wear-prone parts are easy to replace.

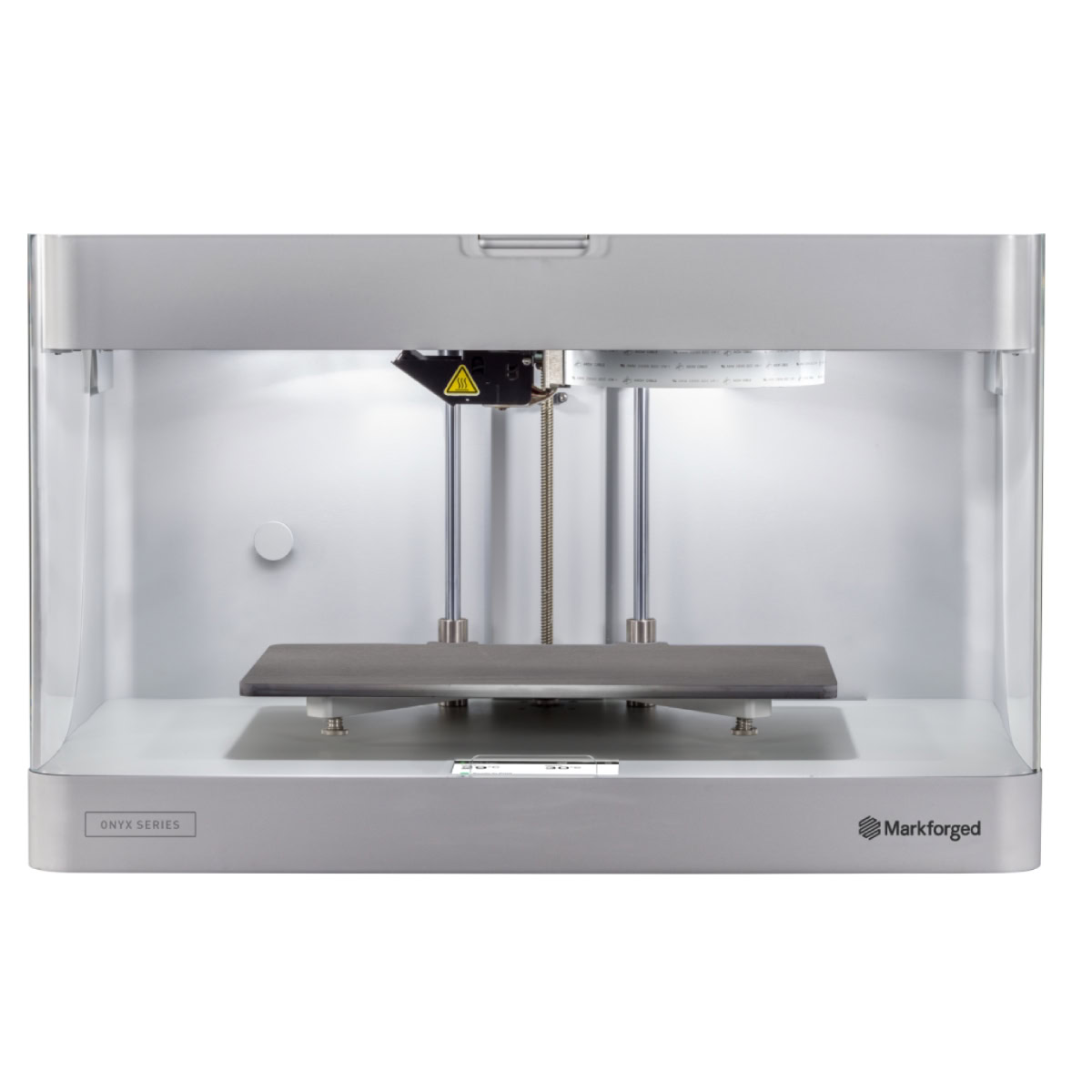

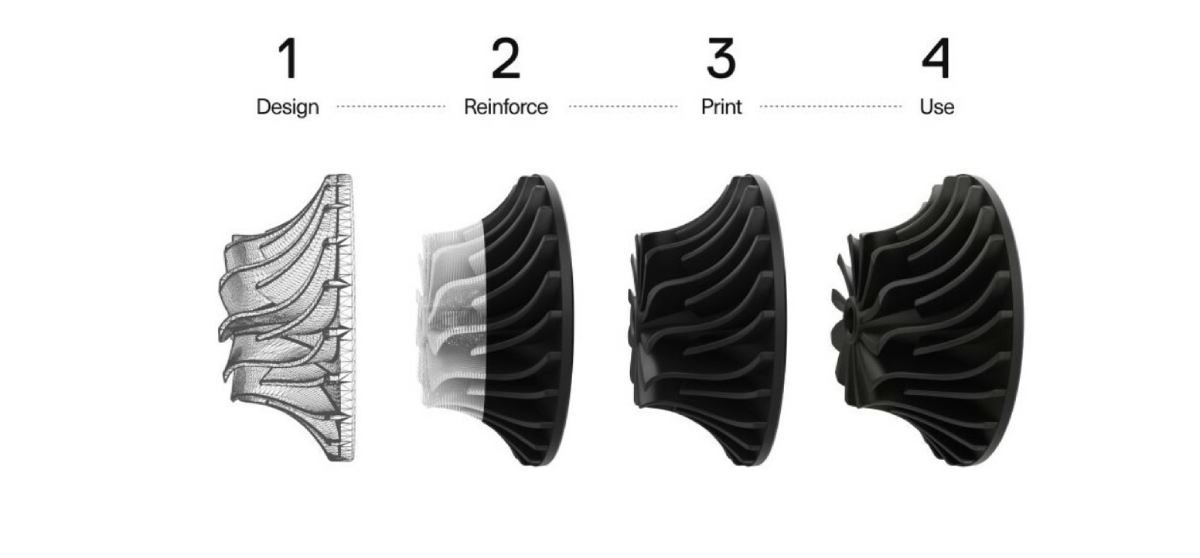

Strength and wear resistance of parts printed on the Markforged Mark Two aluminum 3D printer.

Due to the strength of the extruders in the Mark Two CFR, continuous fiber reinforcement allows you to get products of unique strength with characteristics that are not inferior to aluminum parts.

At the same time, the cost of manufacturing by traditional methods is much higher than 3D printing. The production time for simple parts from development to complete readiness is measured in hours, not months. Printing using closed-cell filling technology (several geometries are available) significantly reduces the weight and cost of the product, without loss of quality.

Presentable appearance and excellent characteristics of advanced Onyx materials

3D printing with Onyx material allows you to get not only durable, but also beautiful products. Filling with carbon fibers does not spoil the aesthetics of the nylon thread: get products with a perfect surface! Markforged Mark Two supports printing with carbon fiber reinforced nylon. A full range of continuous fibers can be used. The strength of finished products is 26 times higher than in products printed from ABS.

Markforged Mark Two software – convenient operation and production management

After designing, the part is loaded into the browser version of the Eiger Cloud program. A few simple settings, depending on the choice of material, and you can start printing. For more complex tasks, paid versions of the software are available.

Scope of application of the Markforged Mark Two 3D printer

The aluminum industrial Markforged Mark Two printer can be used:

• For printing clamps, clamps, templates, fixtures for machines.

• For the manufacture of prototypes, including functional ones, which will subsequently be used in the final product.

• Unique or specialized tools that are impossible or difficult to manufacture in another way.

• Spare parts of a unique property, rare or difficult to manufacture in another way.

• Cases for gadgets and electronic devices.

• Brackets for fastening various elements.

• Decorative items, models, souvenirs.

The modern compact 3D printer Markforged Mark Two will help you organize your work processes more optimally and autonomously, reduce the cost of production, and speed up the manufacture of spare parts and components. Develop together with modern technologies!

Technical specifications

| Printing Technology | Composite base yarns, continuous fibers Continuous Fiber Reinforcement (CFR) |

| Build Field (mm) | 320*132*154 mm |

| Ø Of Plastic (mm) | 1,75 |

| Number Of Extruders | 2 |

| Chamber Type | Closed |

| Heating The Chamber | Yes |

| Autocalibration | Yes |

| Feeder Type | Direct |

| Layer Height (micron) | 100 – 250 |

| Extruder Construction Type | Second generation extruder, detection of plastic absence |

| Leveling System | Automated Bed Leveling, Adaptive Bed Leveling |

| Maximum Chamber Temperature (°C) | 60 |

| Automatic Filament Switching | Yes |

| Platform Heating | Heating, automatic alignment, replaceable printing sheets |

| Platform Material | Composite material with precise ground covering |

| Internal Part Geometry | Closed Cell or Solid Infill |

| Supported Materials | Onyx®, Nylon, Smooth TPU 95A, Precise PLA, Carbon Fiber, Fiberglass, Aramid Fiber (Kevlar®), HSHT Fiberglass |

| Features | Precision design Continuous Fiber Reinforcement (CFR) Filling: solid or closed cells |

| Software | Eiger Cloud |

| Connectivity | Wi-Fi, Ethernet |

| Power Requirements | 100–240 VAC, 150 W (2 A peak) |

| Manufacturer Country | USA |

| Weight Netto (kg) | 16 |

| Dimensions Netto (mm) | 584 x 330 x 355 |

Reviews

There are no reviews yet.