- Stock: Price on request

- Product code: 00-00011631

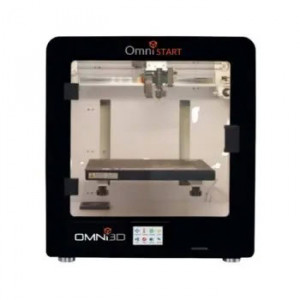

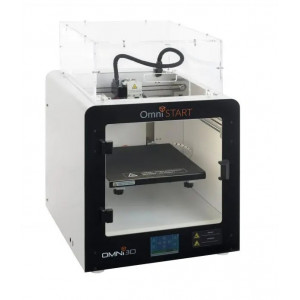

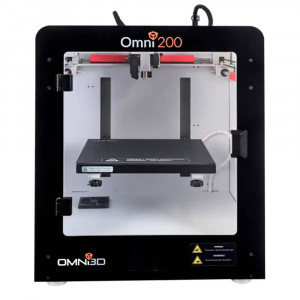

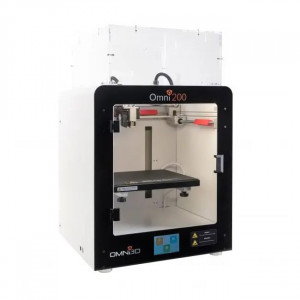

Omni PRO Industrial 3D Printer

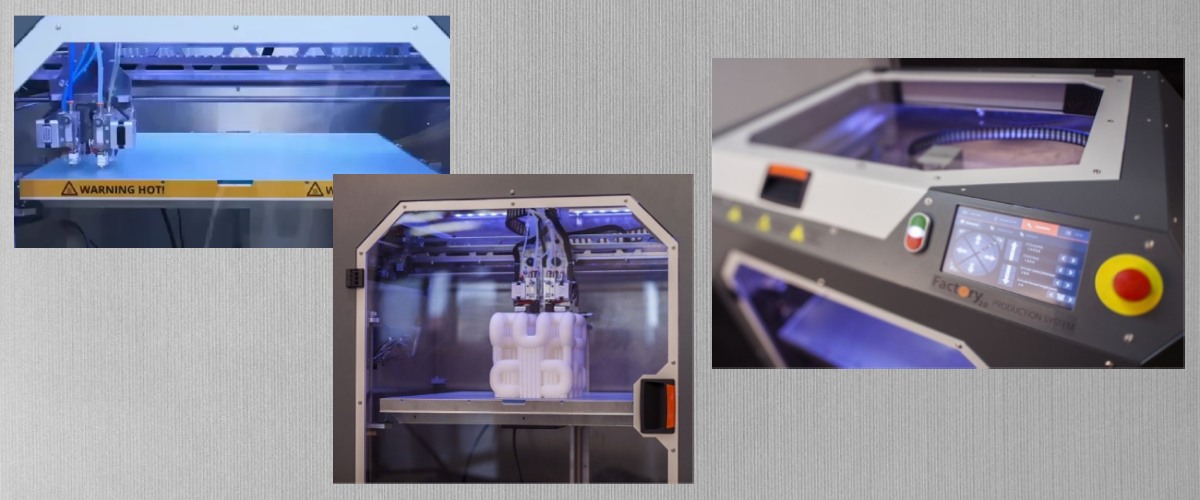

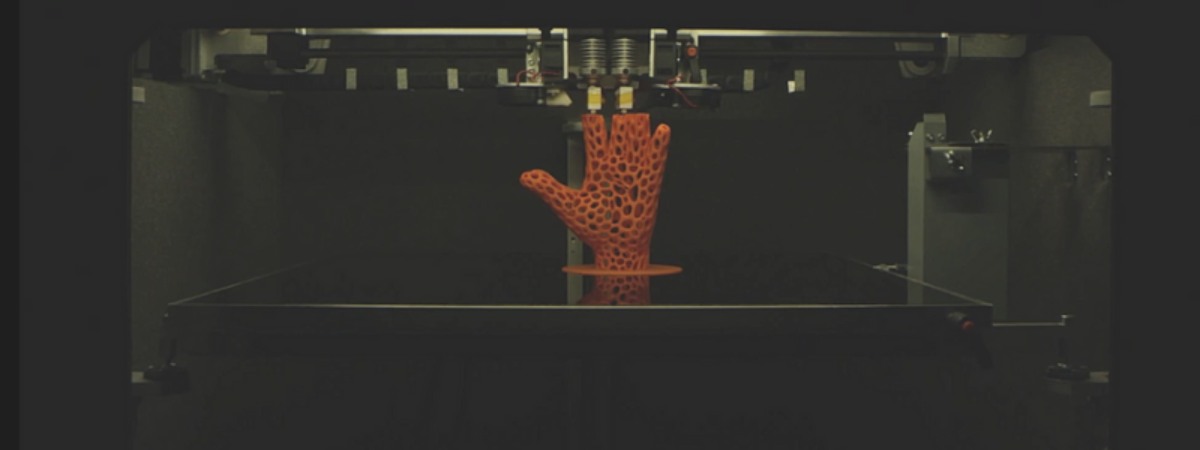

The Omni PRO industrial 3D printer features high performance, precision and extensive automation capabilities. The temperature of the 3D printer’s print head can heat up to 500°C. This allows the use of PEI, PEEK, PEKK, PPS plastics for printing.

The following engineering solutions are implemented in the devices:

- Omni3D Automatic Platform Leveling

- Omni3D Air Circulation System

- Omni3D Cooling System

- Omni3D Filament Flow Control

- Omni3D Web Control

- Omni3D Head Alignment Control

Each of the functions improves user characteristics, and together they help to achieve maximum user convenience, high performance and precision.

Features of Omni PRO Industrial 3D Printers

Omni3D Platform Autoleveling System™

The automatic leveling function of the printing platform guarantees accurate and stable results. The position of the print head does not affect the quality of alignment.

Omni3D Air Circulation™

The system ensures uniform temperature distribution throughout the entire working chamber. This improves print quality and helps to obtain uniform parts.

- Exclusive patented Omni3D Cooling System™

The extruder cooling system works directly in the heated chamber. This improves thermal management and allows for high dimensional accuracy. - Omni3D Filament Flow Control™

The technology provides precise control of the filament feed. This ensures stable material extrusion and high-quality printing. - Omni3D Head Leveling Control™

The system automatically adjusts the extruder height. This ensures reliable layer adhesion and dimensional accuracy during printing. - Workspace in Omni PRO production 3D printers

The OmniPRO 6 printer has a print volume of 500 × 500 × 500 mm. This allows you to produce large-format objects or print several small parts at the same time. - The Omni3D Web Control system provides a wide range of options for remote control and monitoring of the 3D printer.

Remote control capabilities for Omni PRO production 3D printers

- Camera integration. The built-in camera allows you to monitor the printing process in real time.

- Remote control. The printer is fully controlled via a local network, providing convenient access from any device.

- Connection via a browser. You can control the printer from a laptop or phone using a web interface.

- Simple interface. An intuitive menu makes control easy even for novice users.

- Remote update. Software updates are performed remotely, without the need for physical access to the device.

- Event logging system. All printer actions are recorded, and reports can be downloaded as an archived file (ZIP format) for analysis.

This system makes printer control convenient, efficient and accessible from anywhere.

Technical characteristics of Omni PRO 3D printers

- Print technology: FFF (fused filament fabrication)

- Print volume: XYZ 500 x 500 x 500 mm

- Chamber: Closed, insulated and actively heated

- Min. layer height: 50 µm

- Print platform: Heated, easily removable and replaceable PEI surface

- Number of print heads: 2 – electronic lifting system

- Drive type: X, Y, Z axes – ball screw drives; all drives with encoders

- Nozzle diameter: 0.2 / 0.4 / 0.6 / 0.8 / 1.0 mm

- Filament diameter: 1.75 mm

- Max. print speed: 120 cm³/h

- Positioning accuracy: +/- 1.56 µm. All axes (theoretical)

- Printed part accuracy: +/- 0.12% (min. +/- 0.12 mm)

- Automatic platform calibration: Yes

- Air filtration: CARBON + HEPA

- Max. head temperature: 500 °C

- Max. platform temperature: 180 °C

- Max. chamber temperature: 140 °C

- Built-in filament dryer for 4 spools: Yes (max. 4 x 3 kg), up to 120 °C

- Automatic filament change: Yes

- Built-in accessory box: Yes

- Communication SD card, Ethernet, WiFi, USB

- Control 10.1 inch LCD, website, camera

- Software: Simplify3D

- Predefined print settings: Yes, for Omni3D filaments and Omni3D approved filaments.

- Supported files .stl, .obj, .3mf, .gcode, .factory

- Power: 230V/50Hz (optional 110V/60Hz)

- Max. power consumption 3kW

- Printer dimensions: 160 x 110 x 150 cm

- Printer weight: 500 kg

- Safety certification: CE

- Warranty: 12 months (with the possibility of extension)