- Stock: Price on request

- Product code: 00-00011628

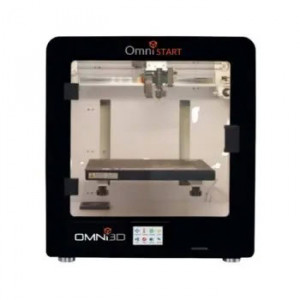

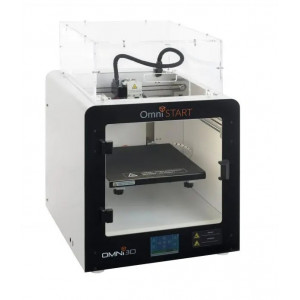

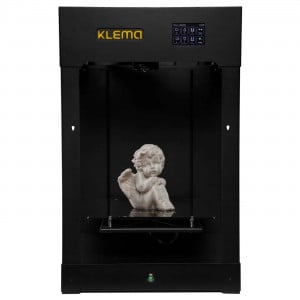

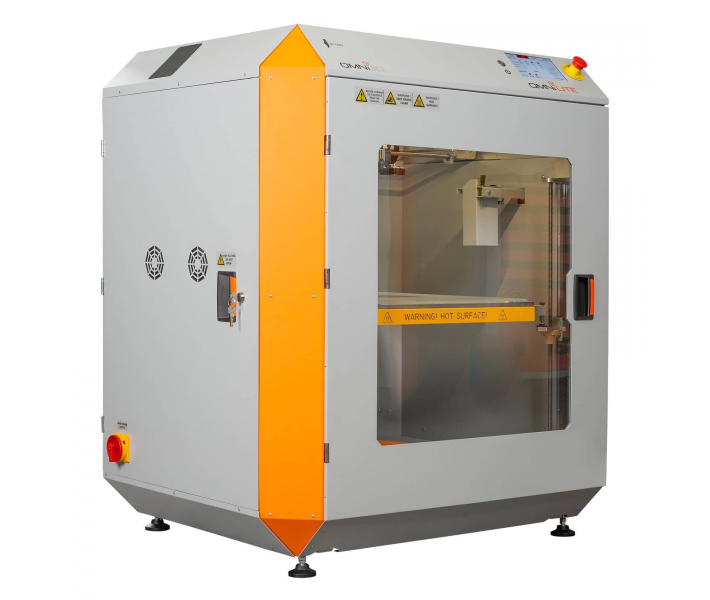

Omni LITE Industrial 3D Printer

The Omni LITE industrial 3D printer is designed for industrial use. This simple and reliable machine provides fast printing with compliance with quality standards for mass production.

Why to use Omni LITE?

- Large print area of 460x460x600 mm.

- 2 extruders with an operating temperature of up to 360 ° C.

- Optionally, it is possible to increase the temperature of the extruders to 420 ° C.

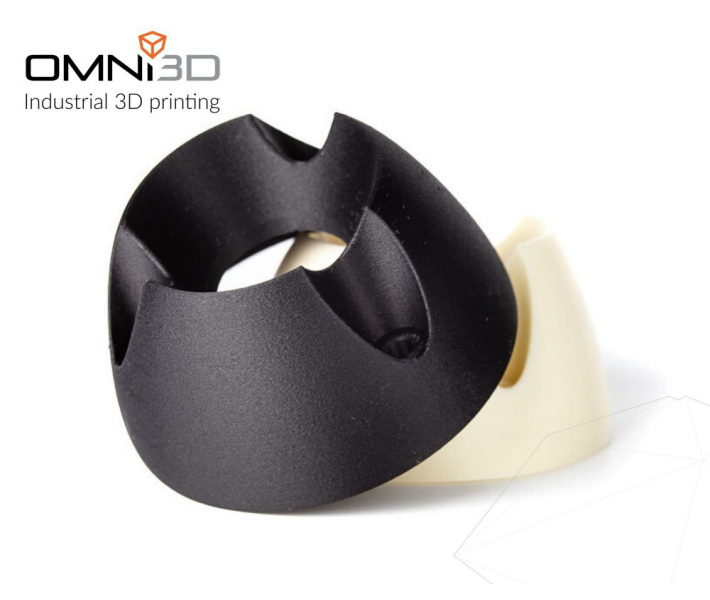

- Standard polymers (PCTG, PLA, PETG, TPU-93A) and engineering plastics (ABS, ASA, ODS-20, PETG, HIPS, Carbon, PP) are used for printing.

- The device is easy to use and manage and can support continuous production in compliance with industrial standards.

- Simple organization of web management of several 3D printers.

Main technical features of Omni LITE

- Working area: 460x460x600 mm

- Printing temperature: 360°C

- Working table temperature: 150 °C

- Printing speed: 86 cm³/hour

- Automatic table leveling system

- Remote viewing via webcam

- Ability to create an online printer group management

- Supported file formats: .stl, .obj, .3mf, .gcode, .factory

Production 3D printer with a large working area

The optimal print area size allows 3D printing of a large part or a group of small ones. This saves time and materials for 3D printing.

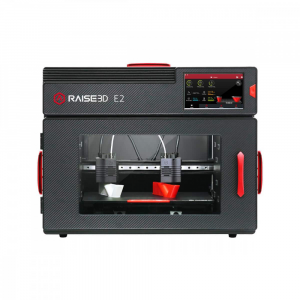

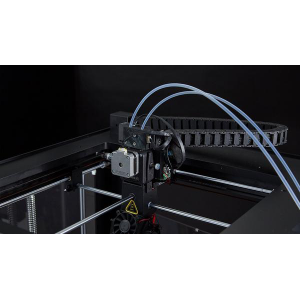

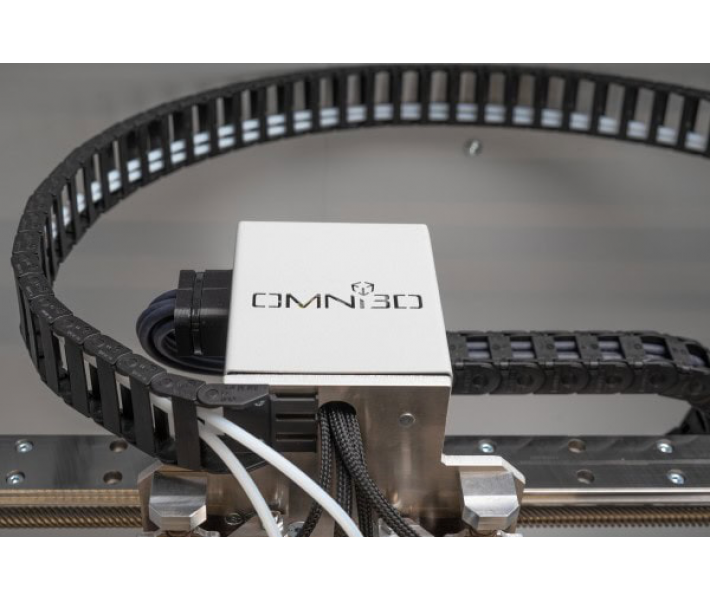

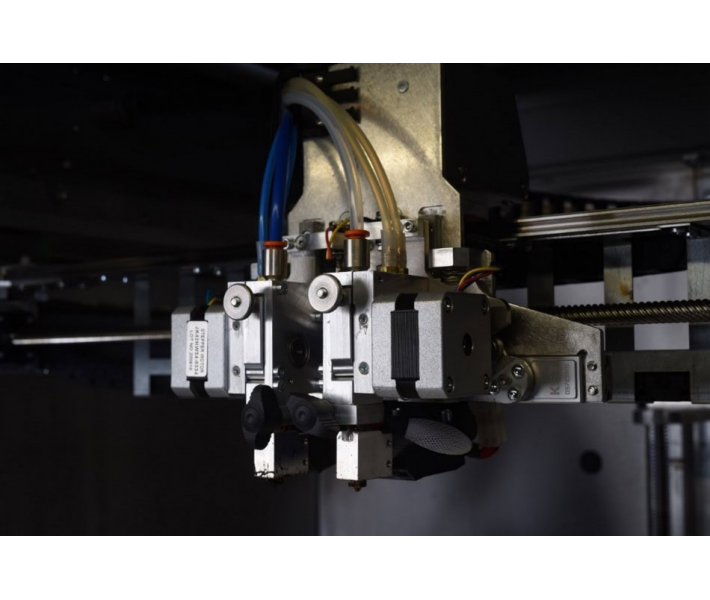

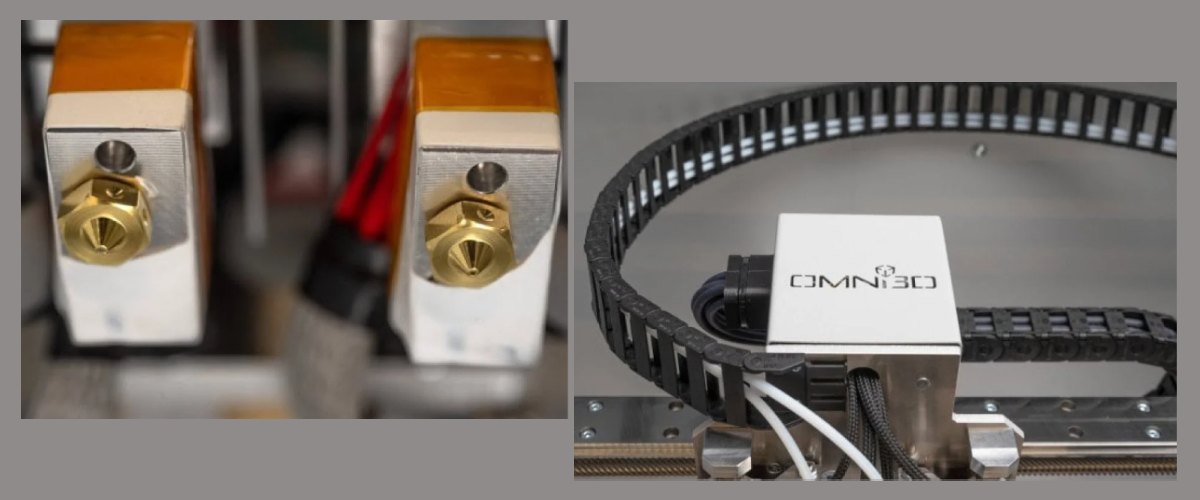

2 extruders with filament presence and movement indicator

During one printer cycle, 2 different materials can be used. One head can print a part using high-grade plastic. At the same time, another head can print supports with a simpler material.

Web-based management of a farm of industrial 3D printers

Omni3D Web Control™ is a system for remote viewing and print management. Thanks to modern software, a printer or group can be controlled via a website. If you buy a production 3D printer, you can quickly organize the launch of printing equipment and control its operation remotely.

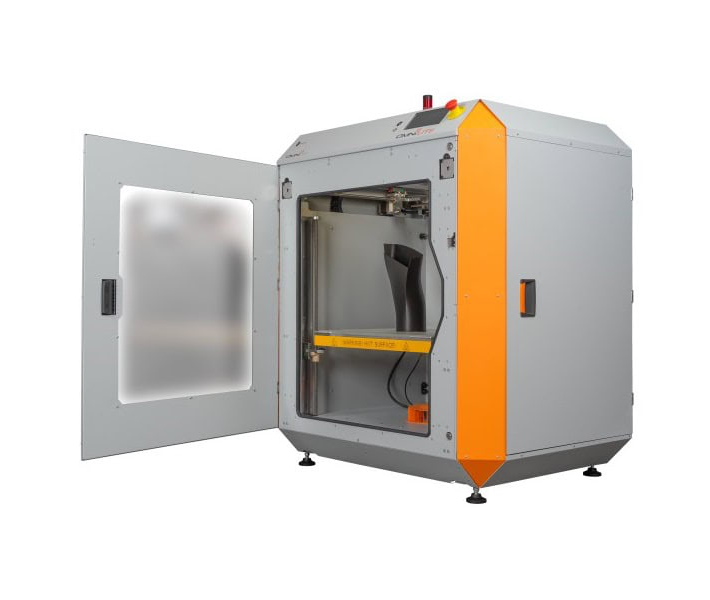

Automatic table leveling in Omni LITE

Thanks to the system of 3 motors along the Z axis, the manufacturer has provided the Omni3D Platform Autoleveling System™. Automatic table leveling is performed by constantly checking the height of the platform with the tip of the nozzle to maintain high print quality.

Automatic Extruder Height Control

Direct measurement of the Z-axis distance between the left and right extruders is provided by Omni3D Head Leveling Control™.

With automatic extruder height control, you can:

- Automatically calibrate the distance between the bed and the nozzle.

- Automatically adjust the height of the nozzles relative to each other.

- Create a grid map, which significantly reduces the impact of unevenness on 3D printing.

Temperature control of the Omni LITE production 3D printer

Omni3D Air Circulation™ is a unique air circulation system. It helps maintain a constant temperature in the working chamber. This allows you to achieve ideal printing parameters with minimal deviations in geometry.

Reliable and easy-to-use production 3D printer Omni LITE will help optimize printing, rationally use printed materials, reduce the time of manufacturing parts without loss of quality.

| Omni LITE Specifications | |

| Printing Technology | FFF |

| Minimum Layer Height (microns) | 50 – 600 |

| Construction Field (mm) | 460*460*600 |

| Ø Plastic (mm) | 1,75 |

| Max Nozzle Temperature (°C) | 360 (optional 420) |

| Number of Extruders | 2 |

| Working Chamber Type | Closed |

| Filament Chamber Type | Closed |

| Chamber Heating | Heating the Chamber |

| Drying Plastic | No |

| Autocalibration | Yes |

| Feed Mechanism Type | Direct |

| Extruder Design Type | Double head, electronic lifting system |

| Nozzle Diameter (mm) | 0.2, 0.4, 0.6, 0.8, 1.0 |

| Printing Accuracy (µm) | +/- 120 |

| Maximum Chamber Temperature (°C) | 50 |

| Max. Platform Temperature (°C) | 130 |

| Platform Material | Glass ceramic surface |

| Supported Materials | ABS, ASA, PET-G, PETG CARBON, CF PA-12, PLA, TPU-93A, PVA |

| Air filter | Carbon + HEPA (optional) |

| Control | 7″ LCD touch screen |

| Availability of a Video Camera | Yes |

| Peculiarities | Emergency shutdown, HEPA filter (optional), door sensor, end of thread sensor, power failure protection |

| Supported File Types | STL, OBJ, 3MF, GCODE, FACTORY |

| Software | Simplifi 3D |

| Connection | SD cart, USB, Ethernet, WLAN |

| Nutritional requirements | 100-230В, ~10А, 50-60 Гц, 2200 Вт |

| Country of Origin | Poland |

| Warranty Period (months) | 12 |

| Certificate | CE |

| Net Weight (kg) | 250 |

| Dimensions Net (mm) | 1180×1050×760 |

| Operating Environment Temperature Range (°C) | 15 – 35 |