- Stock: In Stock

- Product code: 00-00012977

- Shipping Weight: 660.00kg

Available Options

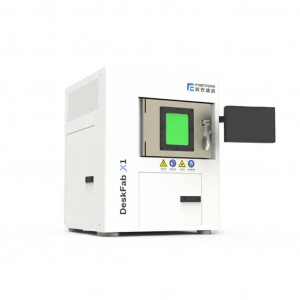

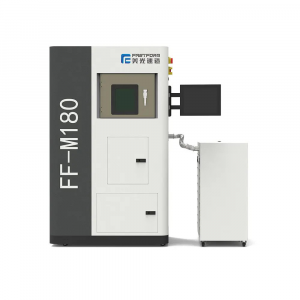

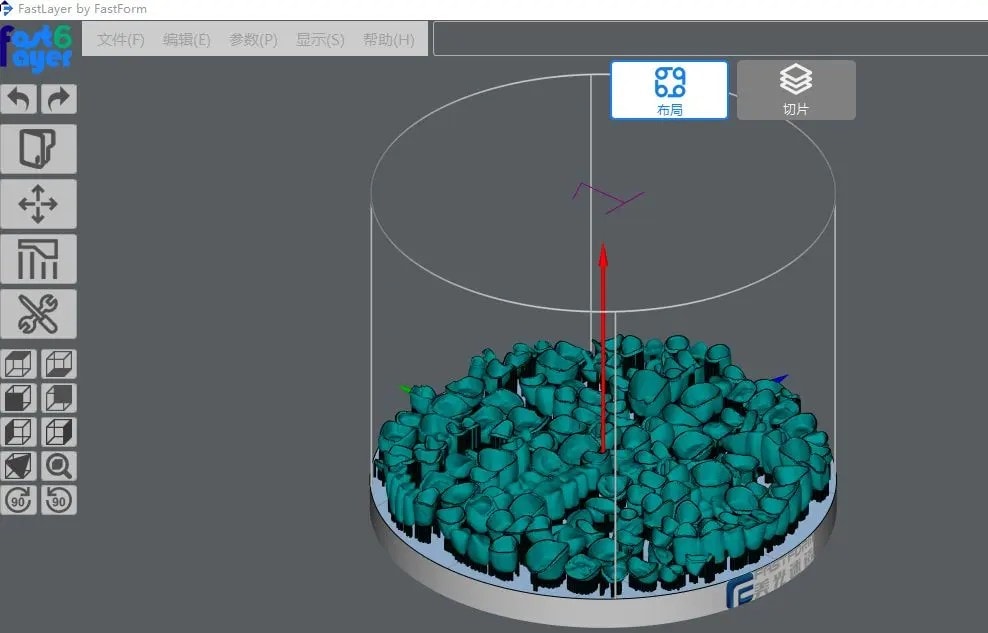

Metal Powder 3D Printing on the FastForm FF-M140C 3D printer

The FastForm FF-M140C is built for Metal Powder 3D Printing. This is a modern professional equipment using the Selective Laser Melting (SLM) technology of metal powder into precise three-dimensional models of complex shapes. The printer is designed for the dental industry, making it possible to produce individual dental components with high precision.

Доступные версии

- Basic configuration: diameter 140 mm x height 100 mm, one laser with a power of 500 W

- Advanced configuration: diameter 140 mm x height 160 mm, one laser with a power of 500 W

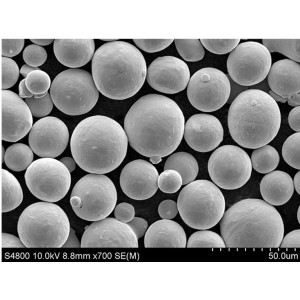

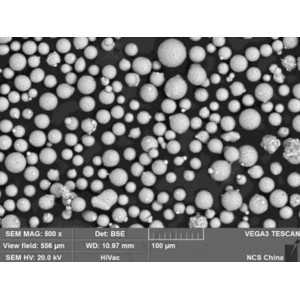

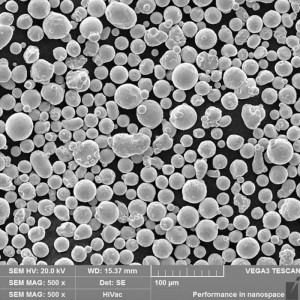

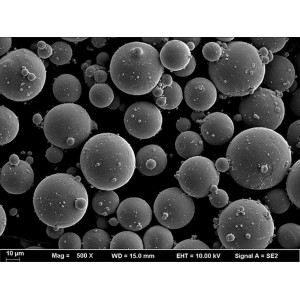

Metals for 3D printing on the FF-M140C

- Cobalt-chrome

- Titanium

- Aluminum alloy

- Stainless steel

- Nickel alloy

- Tool steel

Excellent metal powder 3D printing quality

- Stable optical system.

- Self-developed software.

- One-click automatic printing profile is specially customized for dentistry.

Fast printing

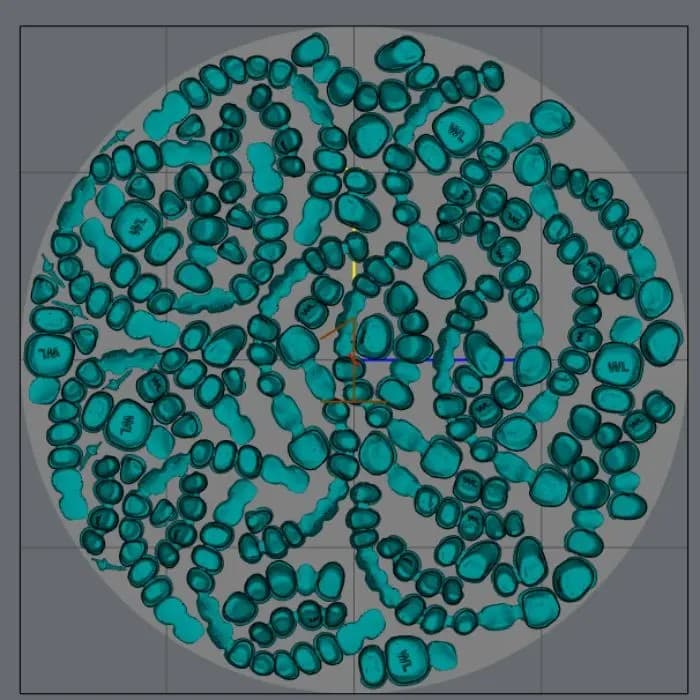

- 150 dental parts for loading.

- No-filter Cartridge Waste, fast powder homogenization.

- Full setup and data processing in 5 minutes.

More safety

- The production process has been advanced and completely safe.

- Connecting with the camera, it supports remote monitoring.

- Strong stability and convenient installation.

Main features of FF-M140C metal printer

- High-speed scanning system of the lower magnetic plate, easy to operate and high production efficiency.

- Especially suitable for small and micro dental laboratories with small needs.

- A very cost-effective metal 3D printer for dentists, affordable for most dental laboratories and small businesses.

- Printing size – 140mm diameter and 100mm height disc printing mold.

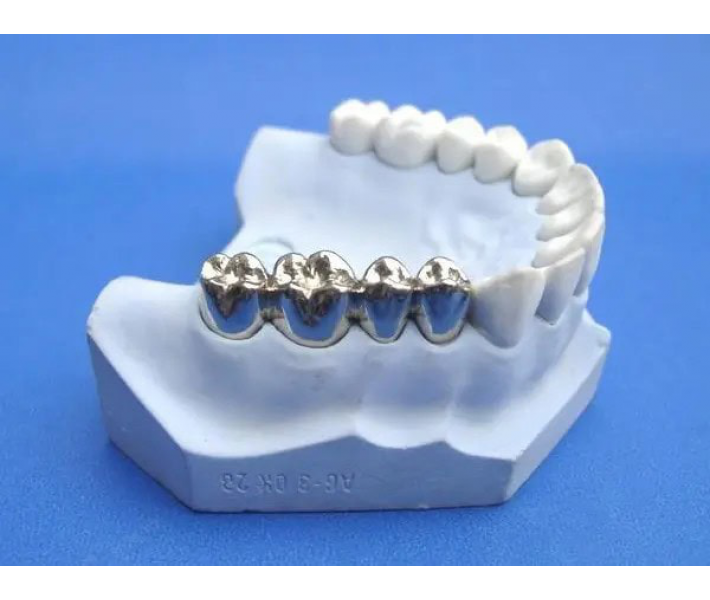

- Each substrate can print up to 120~150 teeth or 12~15 assemblies.

- Metal powders are available in CoCr (cobalt chromium alloy), titanium alloy, pure titanium, and built-in database of Fastform dental 3D printing software.

- Our 3D printer is equipped with a high-brightness laser source with higher power density, which can increase the printing speed with the same printing quality.

- The top-down powder supply system is safer and saves more powder. It is also convenient to add powder when the powder runs out.

- High-precision galvanometer, high accuracy, small drift, accurate position monitoring.

- Adopts powder bed laser sintering technology, additive manufacturing (laser 3D printing).

Software Features

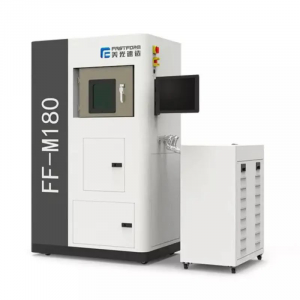

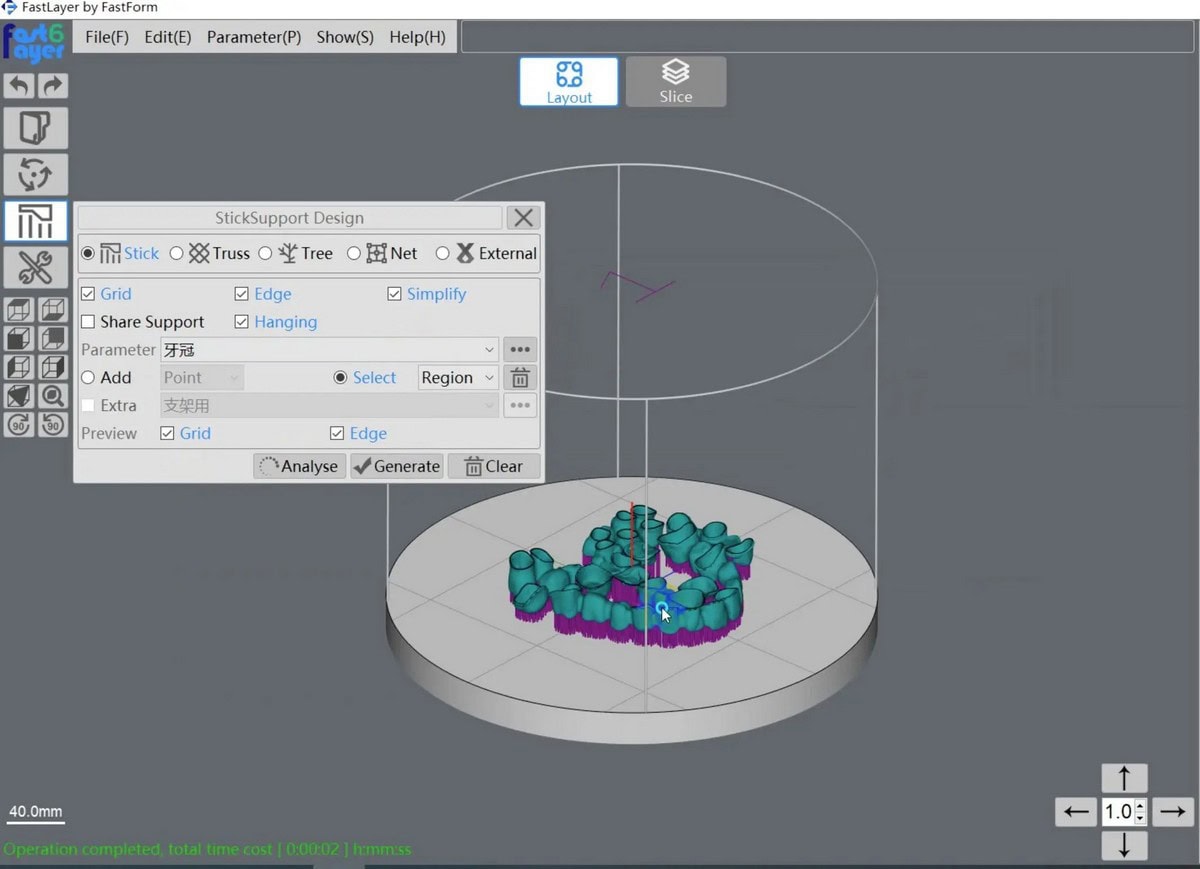

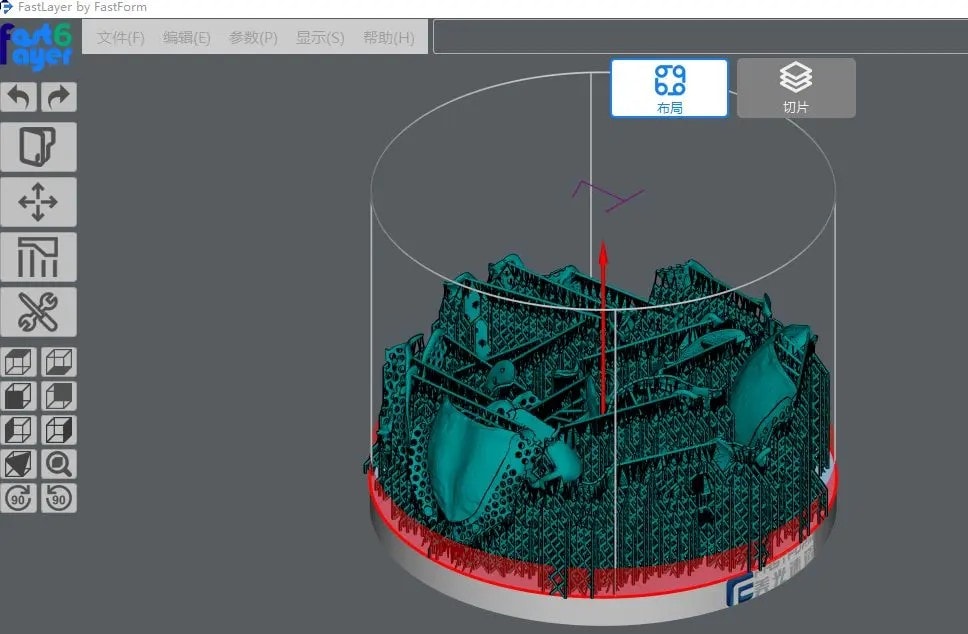

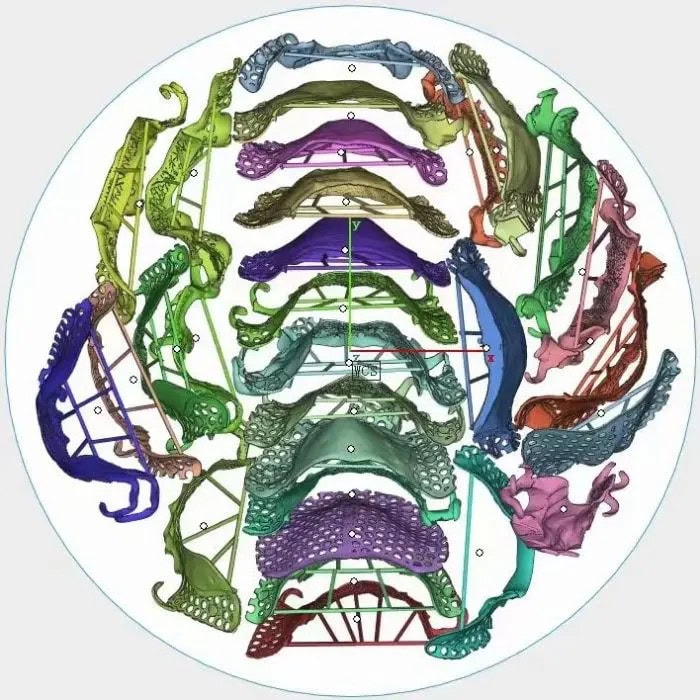

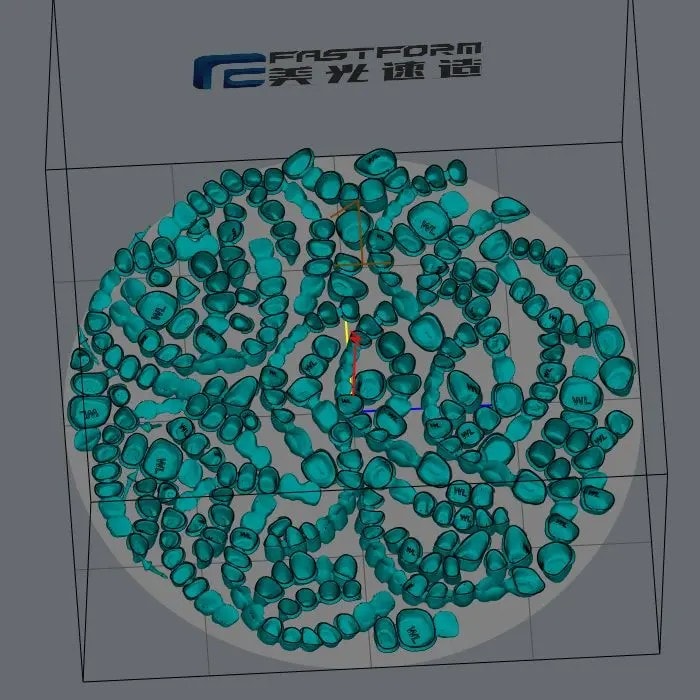

Fastlayer Software

After 8 years of independent research and development, the 3D cutting software can be automatically programmed for precise dental and industrial design.

Complete layout and path planning in one click. Adjust the printing platform according to the size and evaluate any model.

Suitable for various 3D printing files: STL, OBJ, CAD, STEP, 3MF.

Integrate printing parameter databases for various metal materials, independently develop precision parameter libraries for dental cobalt-chromium alloys and titanium alloys, and provide customers with independent development and customized parameter functions.

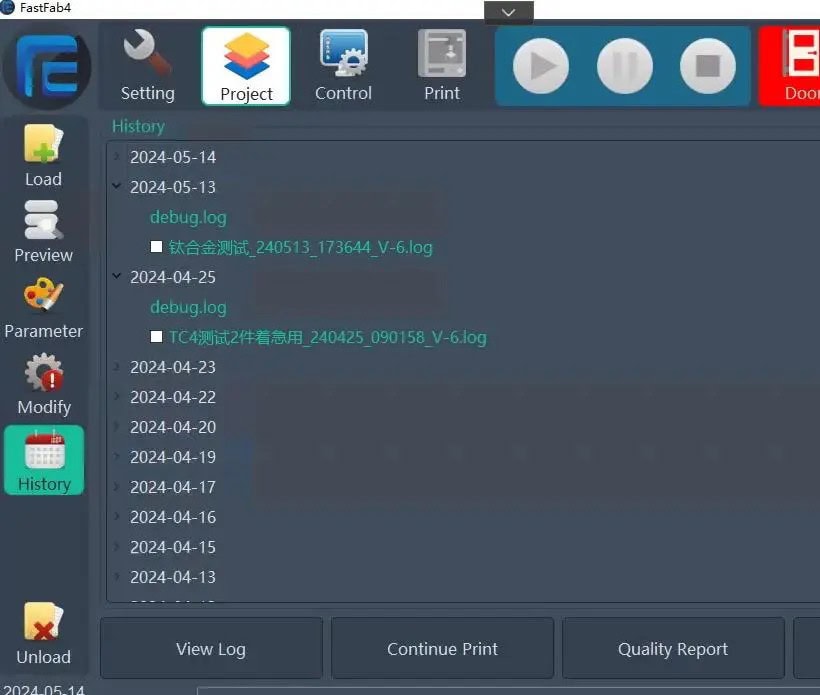

FastFab

Simple user interface, logical and organized layout with various tools and functions.

The performance and responsiveness of the software ensures smooth user experience. It can be easily operated in 5-10 minutes.

The integrated video camera helps operators easily monitor the printing process without the risk of laser radiation.

Print logs record all print data and allow easy auditing of all print applications.

A troubleshooting and analysis helpdesk to improve powder metal print quality.

FastLayer Software – Efficient Layout and Cutting Management

Layout management and cutting processing of complex models.

Up to 100 slicing parameters can fully meet the needs of personalized slicing.

Different models use different slicing parameters, and all slicing processes are completed with one click.

Intelligent multi-core acceleration and slicing processing of any very large and complex model (binary slicing data volume > 10G).

Intelligent slicing repair, even if the model has serious errors, will not significantly affect the printing quality of the model.

A variety of multi-laser welding modes (maximum 36 welding galvanometers) greatly increases the printing size and keeps the printed model from stress concentration.

Accessories and spare parts

- Cleaning kit

- Silicone blade for recoating

- Hardware hand tool

- Stainless steel base plate

- Other necessary tools and accessories

Auxiliary equipment (purchased separately)

- Nitrogen generator

- Vacuum cleaner

- Sieving machine

- Powder drying oven

- Heat treatment furnace

- Sawing machine

- Explosion-proof vacuum cleaner

- Vacuum oven for heat treatment

- Sand blasting machine

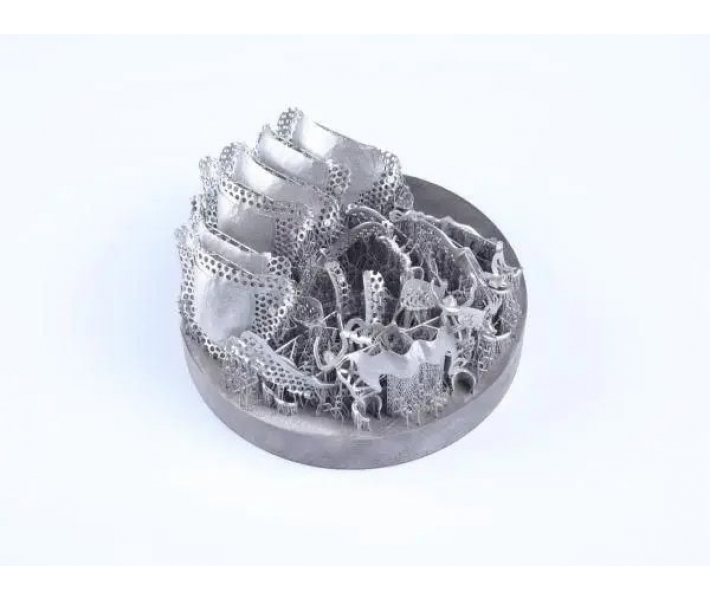

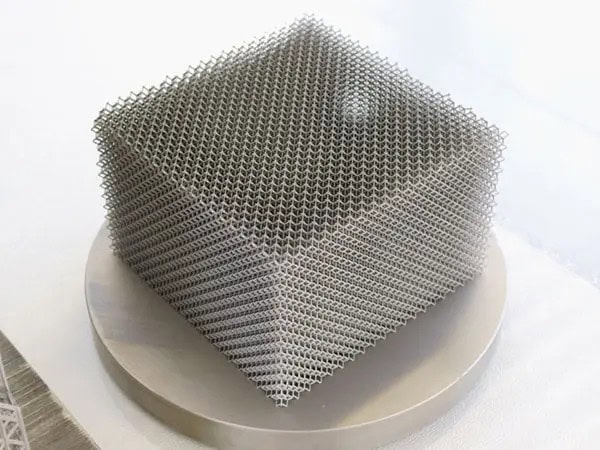

Samples of printing on a metal 3D printer

After-sales service

- 24/7 English language remote service

- On-site assistance

Fastform FF-M140C specifications

- Printing Technology: SLM

- Build Field (mm): D140 x H100 or D140 x H160

- Layer Height (micron): 20 – 150

- Laser Spot Size (mm): 0.05 – 0.08

- Printing Accuracy (µm): 50

- Maximum Scan Speed (mm/s): 10 000

- Production Capacity: 2000 pieces/Year

- Laser Characteristics: 500W (single or dual-laser optional)

- Hopper Capacity (L): 2.5L

- Gas Supply: Ar / N₂

- Oxygen Content: ≤ 0,1%

- Supported Materials: Cobalt-chrome, Titanium, Aluminum alloy, Stainless steel, Nickel alloy, Tool steel

- Cooling System: Water cooling

- Features: Resume printing after power failure, Automatic power off, Top powder feed

- Supported File Types: STEP, IGES, SLC, CLI, STL

- Operating System: Windows 10

- Software: Fastlayer, FastFab

- Connectivity: WiFi

- Power Requirements: Single phase 220V, 1.5 kW

- Air Handling: Permanent filter, service life of at least 30,000 hours

- Manufacturer Country: China

- Warranty Period (months): 12

- Certifications: CE, FDA

- Weight Netto (kg): 450

- Dimensions Netto (mm): 1050 x 870 x 1750

Auxiliary equipment*

For a complete and safe metal 3D printing workflow, you may need additional equipment. We offer a wide range of accessories for FastForm 3D printers.

📌 For more information and assistance in choosing equipment, please contact your manager.

*Not included in the price of the printer.