- Stock: Out of stock

- Product code: 00-00000108

- Shipping Weight: 22.00kg

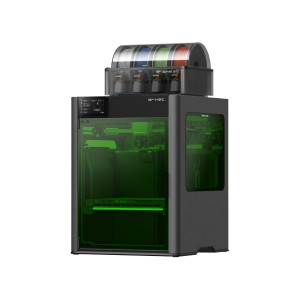

Buy Bambu Lab X1 Carbon 3D Printer in Ukraine

On this page you can buy Bambu Lab X1 Carbon 3D printer, that is conceptualized to avoid common printing problems and combines elegant design with cutting-edge technology in the 3D industry.

The printer creates unrivaled precision finished products at an astounding 500 mm/s and is a versatile enough printer to meet the needs of functional prototyping, decorative and engineering printing, mockups, fixtures, part replacement, and more.

It is the first printer in the X1 lineup and was conceived by the developers to achieve the following 5 goals:

- Easy 3D printing of overhanging parts without the use of unnecessary supports.

- Easy removal of supports from finished products.

- Unattended 24/7 3D printing.

- Bring back the availability and popularity of color 3D printing.

- Creating solid parts from composite materials, for example PA-CF.

Given the claimed performance, they succeeded.

Key features of the X1 Carbon

- Ability to use different colors and materials.

- High quality printing with Lidar 7 µm resolution.

- Ability to upgrade and customize flexibility.

- High-speed CoreXY with an acceleration of 20,000 mm/s².

- Double automatic bed alignment – less manual work.

- Large print volume of 256*256*256 mm – easily print larger and more complex objects.

- Advanced intelligent features to simplify printing and enhance your experience: first layer verified by artificial intelligence, spaghetti detection and automatic bed leveling.

- Print at an astonishing 500 mm/s speed with superb accuracy – reducing waiting times many times over, without compromising on quality. Fast and efficient – while other printers are in the middle of a job, the Bambu Lab X1 Carbon has already completed it!

- Extra cooling, hardened nozzle and direct feeder with carbon reinforced gears – the printer opens up a wide range of material choices including PA, PC, PET and TPU, and specializes in carbon fiber and glass fiber reinforced polymers. This provides greater flexibility in relation to the types of designs that can be created.

State-of-the-art technology for printing from advanced materials

With its performance, advanced technology and sophisticated temperature control system, the X1 is capable of printing more demanding materials.

- All-metal Hotend – 300 °C

- Hardened steel nozzle – 50 HRC.

- Bed heating up to 120 °C.

- Auxiliary 12 W cooling fan of the printing model.

Wide range of printing materials

- PA-CF – super stiff but abrasive carbon fiber filament.

- PA – strong and self-lubricating but very hygroscopic polyamide.

- PC – highly heat-resistant but easily deformed polycarbonate.

- Polymers – multiple polymers for multiple applications in one project.

Evolution based on Artificial Intelligence

- Lidar that measures depth in micrometers

The Bambu Micro Lidar provides micrometer precision in 3D printing. The system measures nozzle height, calibrates flow and scans the first layer.

- Dual Automatic Bed Alignment

The Bambu Lab X1 uses two sets of independent sensors and an algorithm to measure the height of the nozzle relative to the bed. Lidar and analog force sensors cross-check the height – doubly guaranteed.

Inspection system with integrated camera and door sensor

- The built-in camera records the entire printing process so you can monitor printing remotely, or review the recording to determine solutions to potential problems.

- Door Sensor (in development) – A smart sensor allows the printer to pause printing when the door is opened.

- In-camera temperature sensors adjust the speed of the cooler to cool the camera to the desired temperature.

- Filament break sensor.

- Closed loop fan – with tracking of its operation so you can react in time.

- RFID – tracks material type and automatically applies the best settings for your material.

- Odometer – automatically tracks the amount of material used and left behind.

- X1 automatically tracks the belt tension force and offers a semi-automatic way to adjust this parameter using the belt tensioner.

AI helps with 3D printing

AI checks the first layer: tired of waiting for the first layer? Bambu Lab X1 has you covered. The lidar sensor can check your first layer so you can get back to… something else. Spaghetti detection: our artificial intelligence keeps an eye out for spaghetti monsters, so you can sleep easy knowing your printer is protected from this scourge. Spaghetti failure is detected with 86% confidence.

Bambu Lab X1 Carbon superfast 3D printing

How did Bambu Lab get such a speed boost?

- Ultralight carbon fiber rail

- 40W ceramic heater.

- Powerful 12W cooling fan

- Welded steel XY chassis

- Flow 32 mm3/s

- Acceleration 20 m/s²

- Speed 500 mm/s

Use one printer instead of multiple printers without sacrificing productivity. Less latency means faster iteration. Use a default layer height of 0.1mm without worrying about print time. Less time means a smaller carbon footprint on keeping the bed hot.

Clear and smooth lines

The secret to the X1’s smoothness lies in active XY vibration compensation and precise layer height (Z) setting, which, together with high throughput and flow control, results in incredibly smooth and accurate printed lines.

Out-of-the-box printing

The X1 is assembled, configured, calibrated and tested before shipping, so you can enjoy printing right out of the box.

Remote printing from any device

You can send files using Bambu Studio, and you can control your printer anywhere at any time using Bambu Handy, we also support SD card and LAN for printing projects.

It’s time to embrace 3MF

In the STL era, you had to manage model files, print parameters, build instructions, license information, and model images in different locations with different software. With built-in support for 3MF by default, the X1 takes away all of that hassle and now you can manage your entire project in one cloud.

Eco-friendly 3D printing with X1 Carbon

- Up to 80% reduction in carbon footprint

- Up to 20% plastic savings

- 50 dB in silent mode

- VOC filter with activated carbon

Specifications

| Printing Technology | FDM |

| Minimum Layer Height (µm) | 100 |

| Build Field (mm) | 256*256*256 |

| Ø Of Plastic (mm) | 1,75 |

| Maximum Nozzle Temperature (°C) | 300 |

| Number Of Extruders | 1 |

| Chamber Type | Closed |

| Filament Chamber Type | Closed |

| Plastic Drying | Yes |

| Autocalibration | Yes |

| Feeder Type | Direct |

| Extruder Construction Type | All-Metal |

| Leveling System | Micro Lidar Assisted Bed Leveling |

| Nozzle Diameter (mm) | 0.4 (optional 0.2, 0.6, 0.8) |

| Build Speed (mm3/s) | 32 |

| Print Speed (mm/s) | 500 |

| Acceleration (mm/s2) | 20 000 |

| Platform Heating | Yes |

| Maximum Platform Temperature (°C) | 110 |

| Platform Material | Flexible Steel Plate + Bambu Cool Plate, Bambu Engineering Plate (Bambu High Temperature Plate – optional) |

| Open Filament System | Yes |

| Supported Materials | PLA, PETG, TPU, ABS, ASA, PVA, PET, PA, PC |

| Running Noise, dB | < 50 |

| Air Filter | Optional |

| CPU | Quad ARM A7 1.2 GHz |

| Control | 5-inch 1280×720 Touch Screen |

| Assembly Type | Assembled |

| Body Material | Plastic & Glass |

| Video Camera | Optional |

| Features | Bambu Micro Lidar Sensor, Door Sensor, Door Lock During Print, Filament Run Out Sensor, Power Loss Recover, Filament Odometry (Optional with AMS), Cloud Control |

| Operating System | MacOS, Windows |

| Software | Bambu Studio, Superslicer, Prusaslicer, Cura |

| Connectivity | Wi-Fi, Bambu-Bus, Micro SD Card |

| Power Input | 100-240 V, 50/60 Hz |

| Power Output | 1000W |

| Onboard Flash (Gb) | 4 |

| Manufacturer Country | China |

| Warranty Period (months) | 12 |

| Weight Netto (kg) | 13,18 |

| Dimensions Netto (mm) | 389×389×457 |