- Stock: In Stock

- Product code: 00-00013395

- Shipping Weight: 17.40kg

3D Printer Bambu Lab P2S – AI Control, Improved Management

Bambu Lab P2S is a modern desktop 3D printer with an enclosed chamber, an improved modification of the P1S.

It features an updated interface, enhanced airflow control, automation, and extended reliability thanks to AI error control.

The 3D printer has small dimensions and weight, a friendly price, yet its characteristics are close to professional equipment.

Please note! The AMS (Automatic Filament Supply System) is not included. It is available as an optional extra.

Key Features of the P2S Model

- Build volume 256*256*256 mm³.

- 5-inch touchscreen.

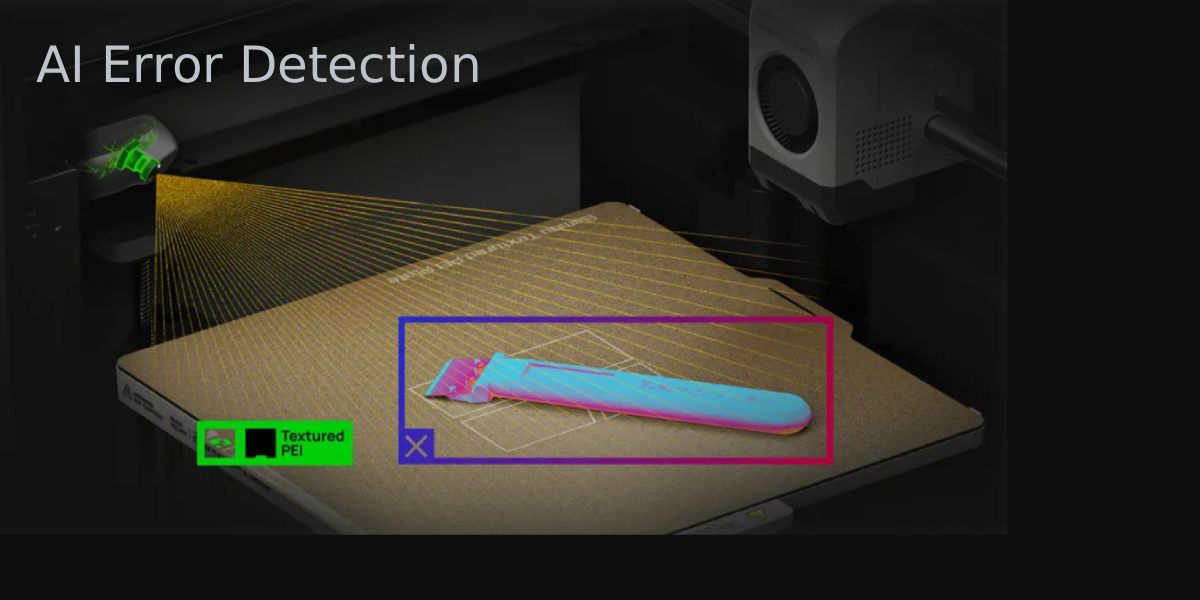

- AI failure detection system.

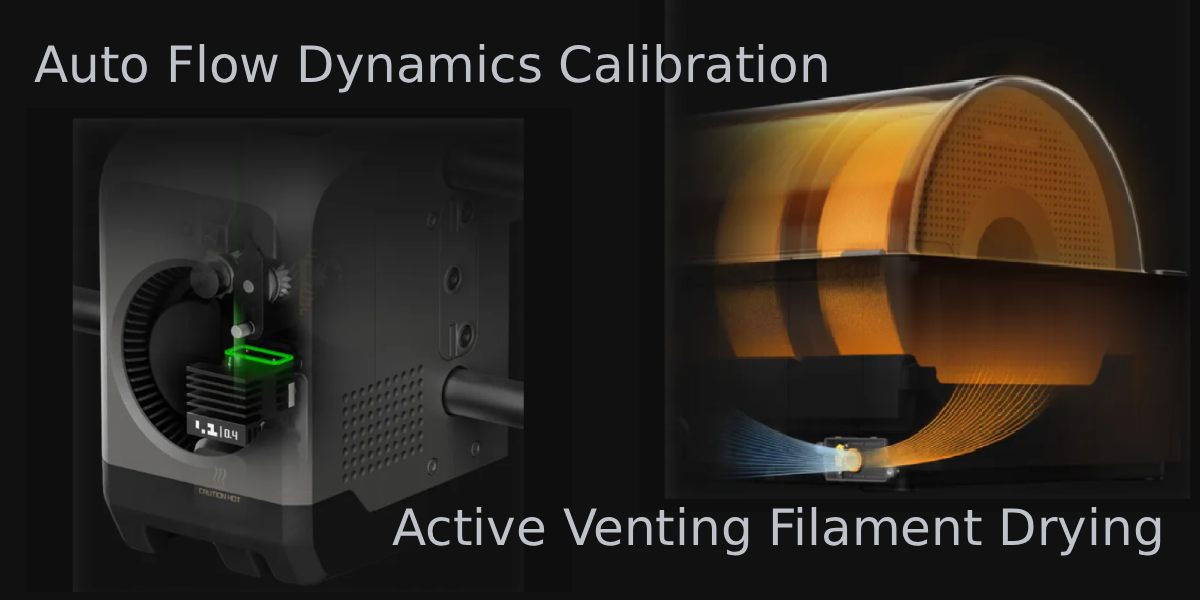

- Automatic flow rate calibration.

- Support for multi-color printing.

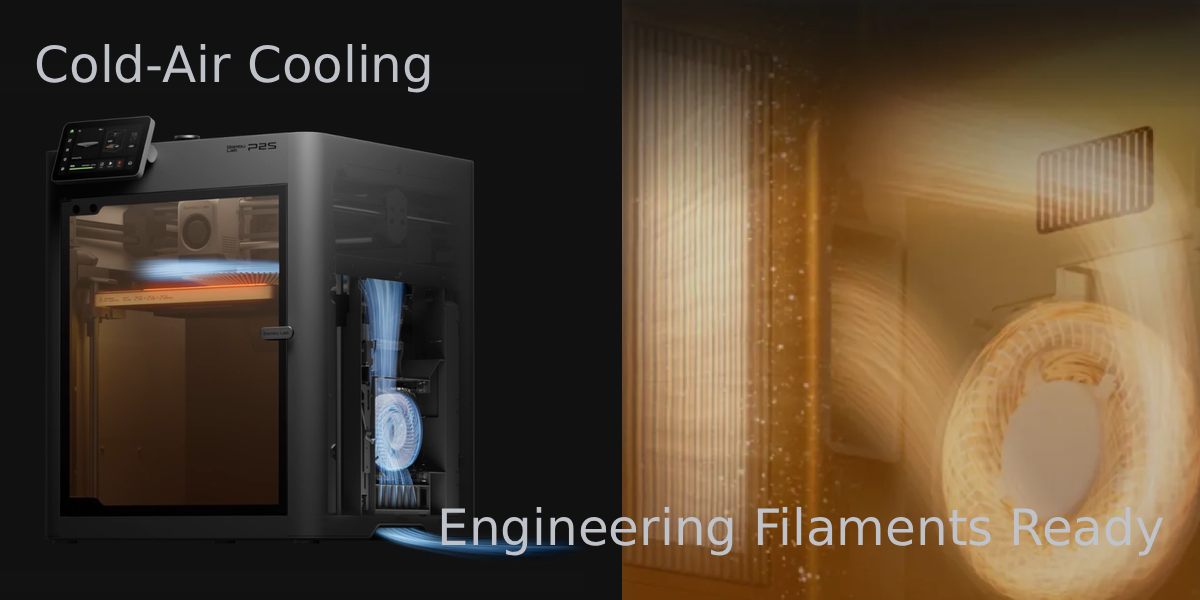

- Cold air stream cooling.

- Active filament drying ventilation.

Key Technical Parameters

- Print Area: 256 × 256 × 256 mm.

- Control: 5-inch touchscreen.

- Nozzle: 0.4 mm, hardened steel.

- Supported Materials: PLA, TPU, ABS, PC (up to 300 °C).

- Machine Dimensions: 392 × 406 × 478 mm.

- Weight: 14.9 kg.

- Connectivity: USB, WiFi, Bluetooth.

The P2S is equipped with the Adaptive Airflow system featuring dampers that regulate air flow and chamber sealing, and also filter the internal air through an activated carbon filter. This allows for better printing of engineering materials, minimizing warpage.

AI Error Detection (monitoring for filament tangles, clogs, printing errors) through visual recognition, which can pause printing upon detecting a problem.

It also includes a camera for monitoring, a filament run-out sensor, and air filtration within the chamber structure.

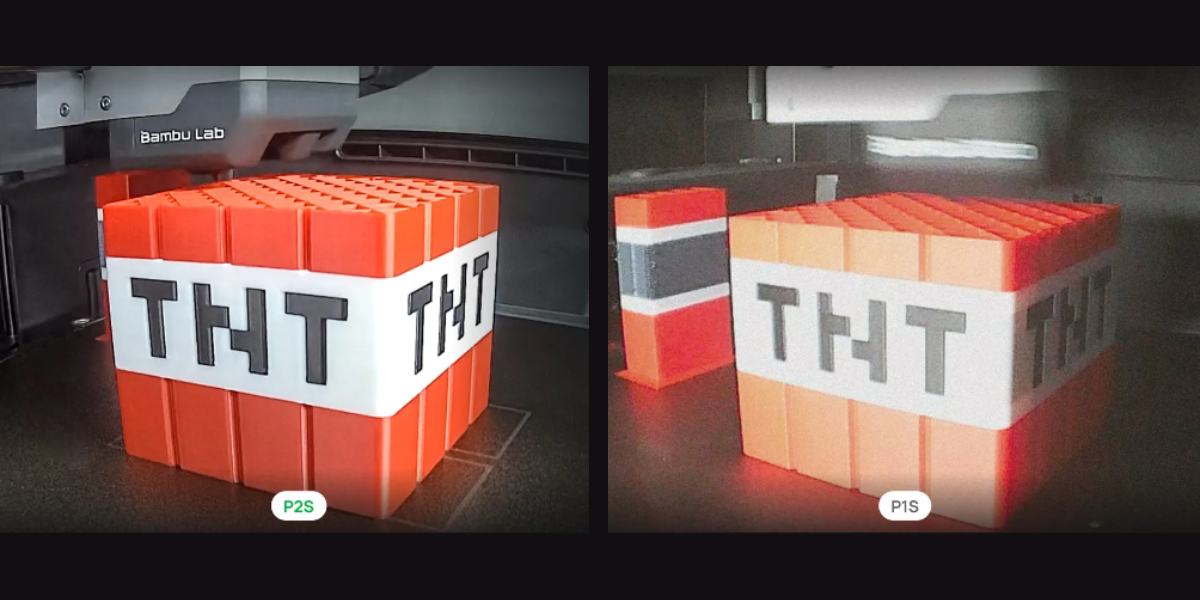

Comparison of Bambu Lab P1S and P2S Models

Comparison with the P1S: The P2S retains the same volume and many basic features in many aspects, but introduces improvements, especially in terms of airflow management, interface, AI monitoring, and reliability.

Advantages and Features of the Bambu Lab P2S

Improved Interface and Control

The Bambu Lab P2S offers a new 5-inch touchscreen, providing a more responsive and modern interface compared to previous solutions.

Adaptive Airflow — Air and Heat Control

The Adaptive Airflow system with dampers regulates the intake/exhaust of air inside the chamber, retaining heat while simultaneously providing filtration through an activated carbon filter. This allows for better handling of materials prone to deformation (ABS, PC) and reduces the influence of the room's microclimate.

AI Error Control

Using built-in AI vision software, the P2S can automatically detect typical defects: "spaghetti," clogs, incorrect filament feeding, and pause printing if necessary, which enhances reliability, especially in long-term tasks.

Software and System Updates

The manufacturer emphasizes that the P2S uses advanced firmware and intelligent system control, making the workflow smoother and more stable.

Compatibility with AMS and Multi-Material Capabilities

The P2S retains support for the AMS (Automatic Material System) for printing with multiple filaments simultaneously; the model can work with the AMS 2 Pro, just like older Bambu Lab models.

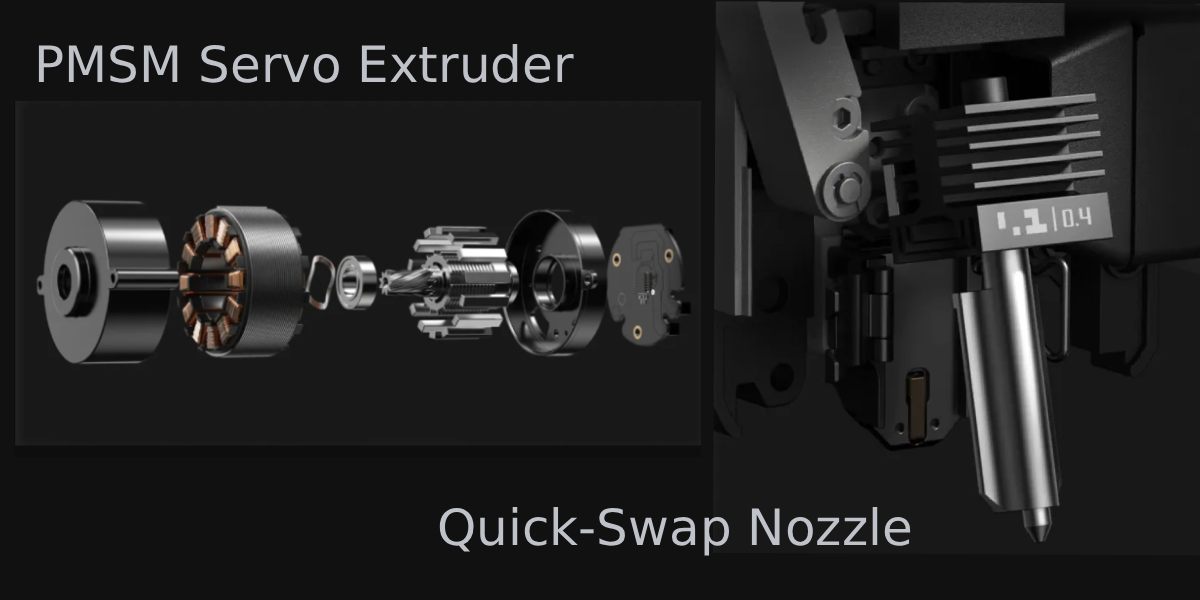

Nozzle Replacement: Ease of Use

As with more advanced models, the P2S allows for quick change of nozzles (0.2 / 0.4 / 0.6 / 0.8 mm) and fast system maintenance, which is important for users printing with a variety of materials.

Balance Between Compactness and Functionality

The machine remains relatively compact (392 × 406 × 478 mm) and not excessively heavy (14.9 kg), making it suitable for workshops, laboratories, and home studios.

Tasks for which the P2S is Designed

- Prototyping — quickly creates precise parts from PLA, ABS, PC.

- Models and layouts — architectural elements, mock-ups, souvenirs.

- Printing technical products — housing parts, functional elements, spare parts.

- Multi-material printing — thanks to AMS.

- Long-term and automated tasks — thanks to AI control and stability.

- Hobby projects — from figurines to parts for DIY devices.

Advantages of 3D Printing with Bambu Lab P2S

- Reliability and stability — automatic error control and adaptive airflow functions reduce the amount of waste.

- Simplified workflow — a modern interface and automation increasingly eliminate manual operations.

- Material versatility — capable of working with technical plastics with chamber support and protection.

- Multi-material capability — the ability to print with multiple filaments via AMS expands the creative range.

- Quality at high speeds — maintaining a volume of 256³ and high speed, it combines efficiency and precision.

- Ease of maintenance — quick replacement of extruder components, AMS support, user-friendly interface.

- Modern technologies — AI monitoring, adaptive airflow control, improved display make it "smarter."

- A buffer between the amateur and professional segments — combining affordability and power.

Technical Specifications Bambu Lab P2S*

| Parameter | Value |

|---|---|

| Build Volume | 256 × 256 × 256 mm |

| Maximum Nozzle Temperature (Hotend) | 300 °C |

| Default Nozzle Diameter | 0.4 mm |

| Supported Nozzle Diameters | 0.2 / 0.4 / 0.6 / 0.8 mm |

| Maximum Bed Temperature (Heatbed) | 110 °C |

| Extruder Type / Feeding | Servo Extruder, increased feeding precision |

| Flow Calibration System | Built-in sensor (eddy current) for material feeding control and regulation |

| Adaptive Airflow | Dampers for regulating air intake/exhaust and activated carbon filter for chamber stabilization |

| AI Error Detection | Built-in computer vision for detecting "spaghetti," clogs, and other defects |

| Camera / Monitoring | High-resolution Live View Camera and improved lighting |

| Quick Nozzle Change | Quick-attachment design for fast replacement of nozzles/modules |

| Sensors and Protection | Door sensors, filament run-out, tangle detection, filament length tracking, power loss recovery |

| AMS Support (Multi-filament) | AMS Support (including the P2S Combo option with AMS 2 Pro) |

| Enclosure Dimensions | ≈ 392 × 406 × 696 mm |

| Weight | ≈ 14.9 kg |

| Additional Features | RFID filament recognition (in AMS), print recovery after power loss, improved firmware |

*The manufacturer may introduce changes to the product's technical parameters without prior notice

Thanks to the expanded capabilities of the Bambu Lab P2S, 3D printing will become even simpler and more comfortable, even for inexperienced users. The manufacturer strives to enable everyone who wants to master modern technologies. Their product is reliable, easy to set up and use, with a high degree of process automation.

New Bambu Lab products and models established in the market can be purchased with delivery in Kyiv on the website or by phone – call us! We will help you quickly master 3D technologies. We offer free training on using the device, warranty and post-warranty service, and information support during operation.

Video about the Bambu Lab P2S capabilities