- Stock: In Stock

- Product code: 00-00013124

- Shipping Weight: 50.00kg

- SKU: H2S Full Laser Combo

Available Options

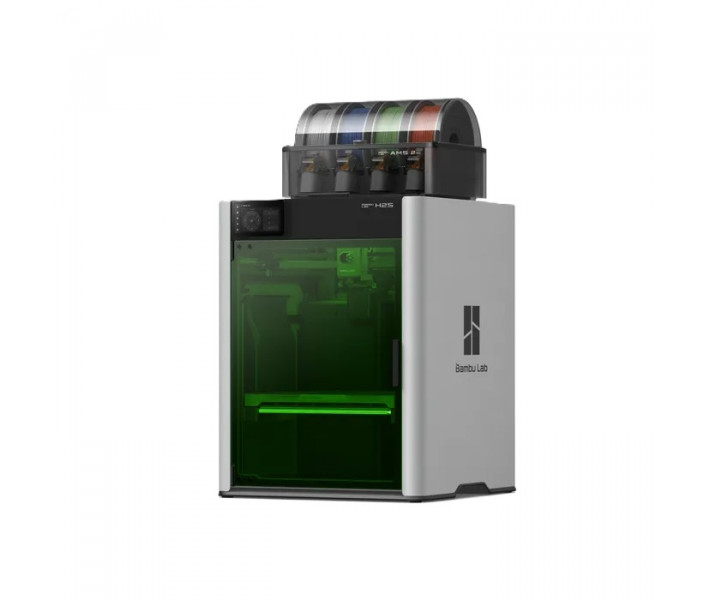

Discover a new era of 3D printing and laser processing with the revolutionary 3D printer Bambu Lab H2S Full Laser Combo. This innovative all-in-one system from Bambu Lab sets unprecedented standards for accuracy, speed, and versatility, empowering engineers, designers, and creators to bring their most ambitious visions to life with unparalleled precision. Whether you're tackling complex engineering filaments or intricate laser engraving projects, the H2S Full Laser Combo is engineered for peak performance and reliability.

Unrivaled Precision in Every Layer

Experience an extraordinary level of accuracy that adapts to your needs. Even as mechanical wear and variances naturally occur over time, the Bambu Lab H2S Full Laser Combo offers an industry-first solution. Thanks to its cutting-edge Vision Encoder, this printer achieves distance-independent motion accuracy of less than 50 μm – a tolerance thinner than a human hair. During calibration, it intelligently compensates for mechanical drift, ensuring consistent, long-term precision and peak operational performance.

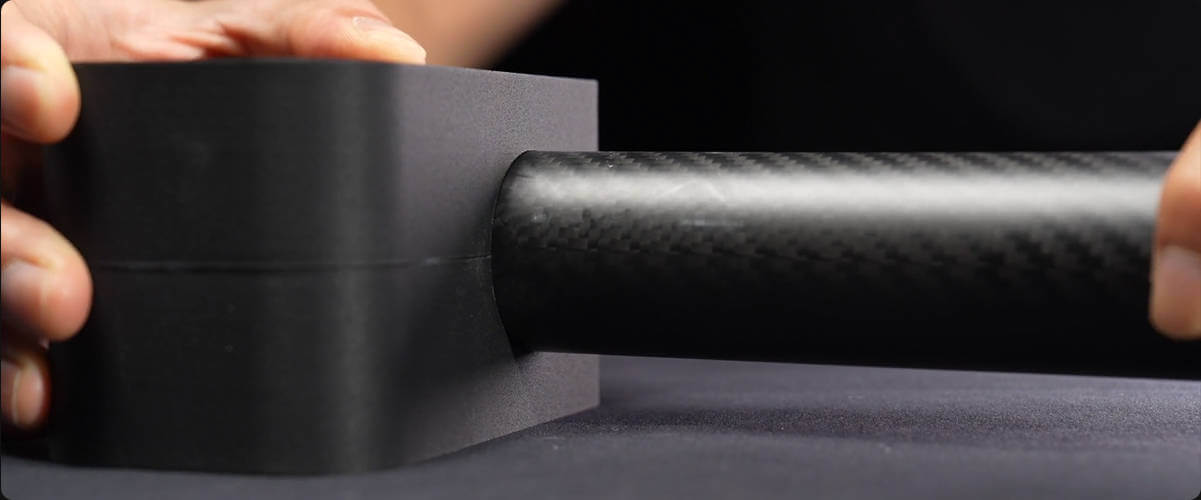

Furthermore, Bambu Lab's innovative Auto Hole/Contour Compensation significantly minimizes printing tolerances, delivering machine-shop-level accuracy for hole dimensions. This empowers you to confidently design and integrate fit-critical parts such as shafts, bearings, and fasteners without the need for frustrating trial and error, making post-print assembly smoother than ever before.

Engineered for Demanding Materials

The Bambu Lab H2S Full Laser Combo is ready for a wide array of engineering filaments, providing unmatched material versatility. Equipped with a 350 °C hotend and an actively heated chamber maintained at 65 °C, it effortlessly supports the entire Bambu filament lineup, ranging from standard PLA and PETG to high-performance PC and PPA. With sophisticated closed-loop fan control and precise thermal management, the H2S actively minimizes warping and deformation, while simultaneously improving layer adhesion. This capability allows you to reliably build large, high-performance parts that are not only functional but also exceptionally strong and durable.

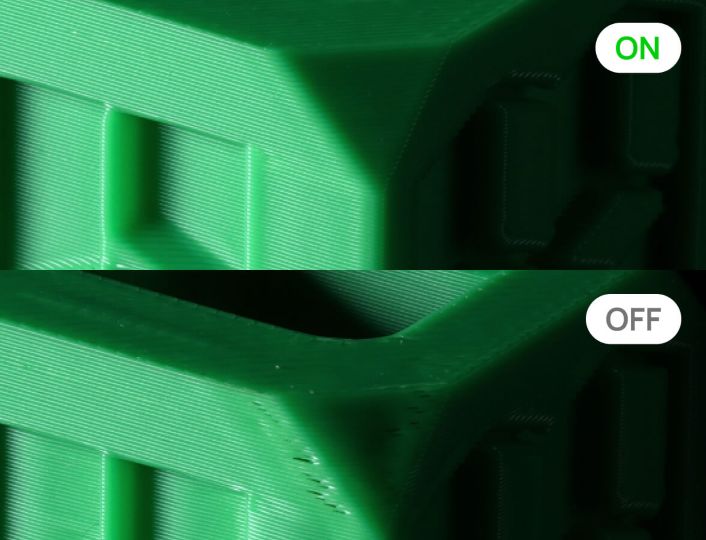

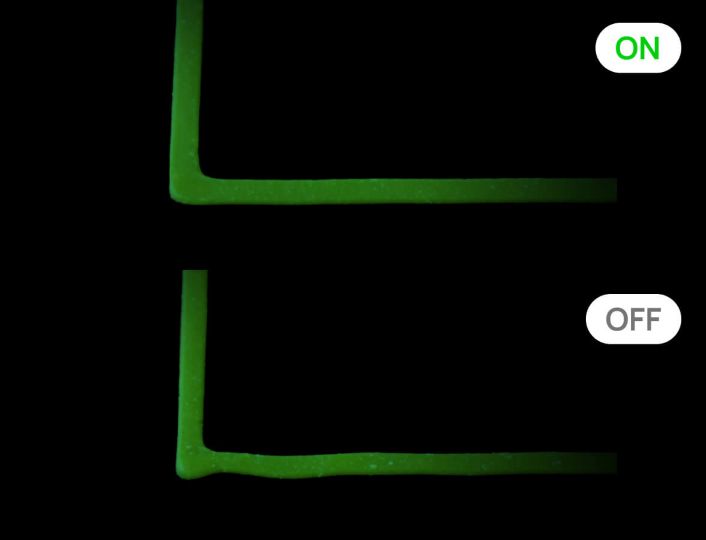

Flawless Surfaces, Razor-Sharp Edges

Achieve truly exceptional print quality with every project. The H2S utilizes a dual-sensing approach, combining the advanced capabilities of its servo motor on the extruder with high-resolution eddy current sensors on the nozzle. This sophisticated system precisely controls extrusion by continuously measuring nozzle pressure and calibrating PA (Pressure Advance) parameters for each specific filament.

The result is consistently smoother surface finishes and remarkably sharp, well-defined edges that elevate the aesthetic and functional quality of your prints.

Dynamic Speed, Consistent Quality

Experience precision in motion like never before. The printer's Active Vibration Compensation technology intelligently neutralizes micro-vibrations and resonance in real-time. This crucial feature allows the H2S to maintain premium print quality even at significantly higher speeds, ensuring that efficiency never compromises the integrity of your creations. The proprietary PMSM servo system from Bambu Lab delivers an impressive 67% more extrusion force, providing robust support for high-flow printing. Paired with a toolhead speed of up to 1000 mm/s and acceleration rates up to 20,000 mm/s², your H2S can operate at full throttle, cutting your printing time by up to 30% while consistently delivering top-tier quality.

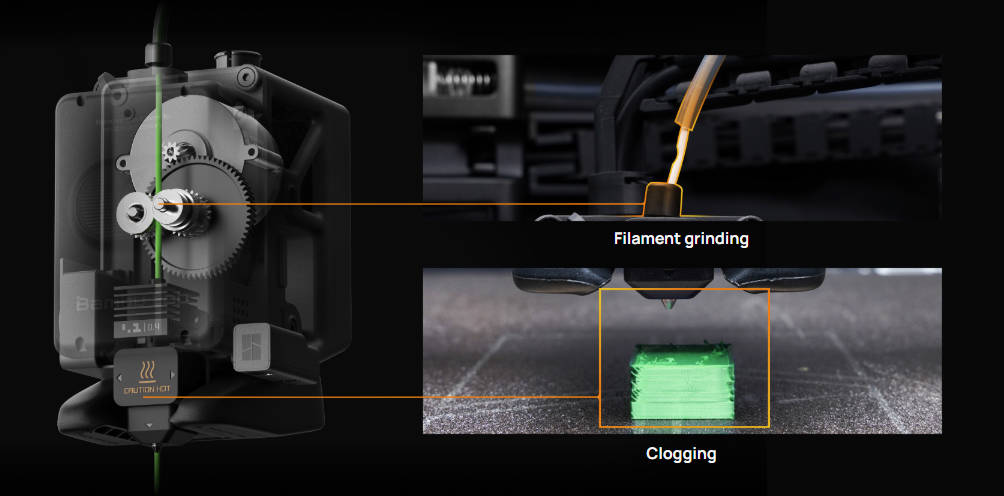

Intelligent Monitoring and Enhanced Safety

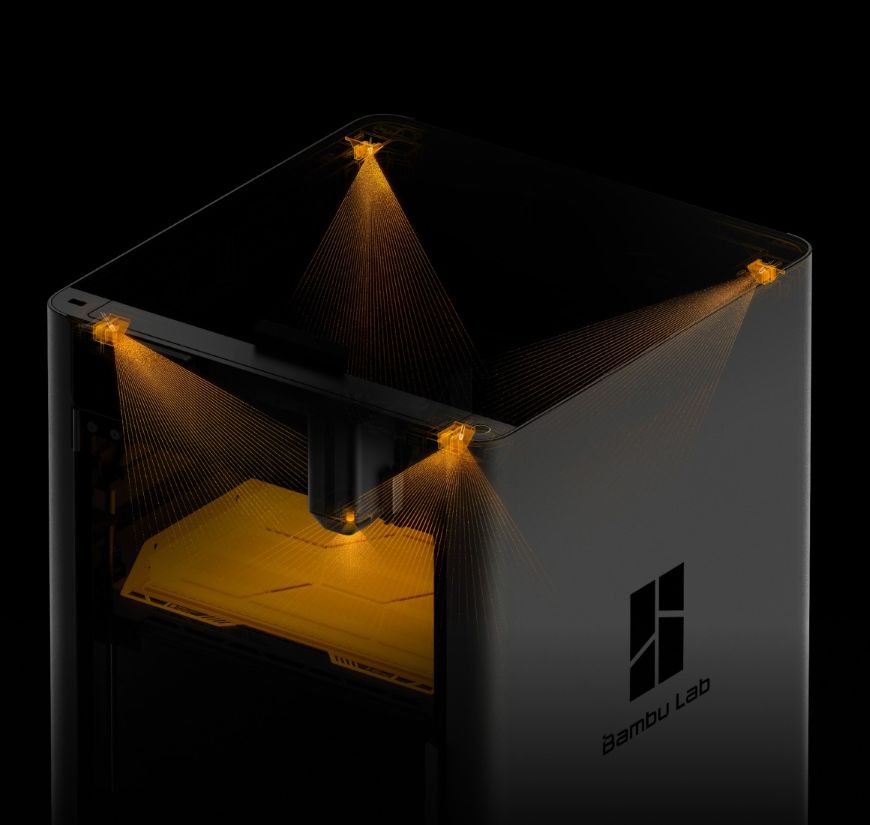

The H2S Full Laser Combo is designed with intelligence that supports your workflow, performing 20,000 checks per second through its closed-loop feedback, real-time control system. The proprietary PMSM servo system dynamically modulates electromagnetic torque vectors, stabilizing extrusion and actively detecting potential grinding or clogs in real-time.

With 23 sensors and 3 cameras strategically placed, every potential risk has its own dedicated detector.

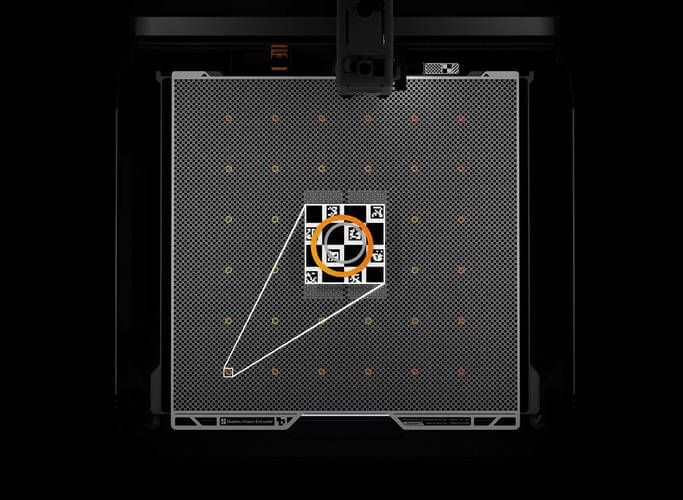

The AI-driven vision system provides real-time monitoring, detecting issues such as clumping, spaghetti failures, and purge chute jamming as they occur, actively preventing failed prints. This same vision system powers advanced features like Live Spatial Alignment for precise laser and cutting calibration, and enhances positional accuracy via Vision Encoder technology.

A comprehensive safety system, including five flame sensors, front-door and top-cover sensors, and an emergency stop button, ensures maximum protection for your projects and workspace.

Integrated Laser Capabilities

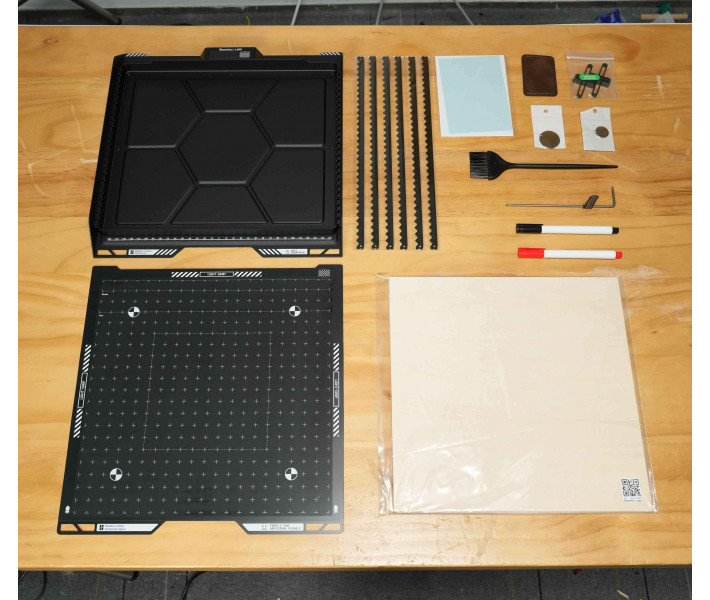

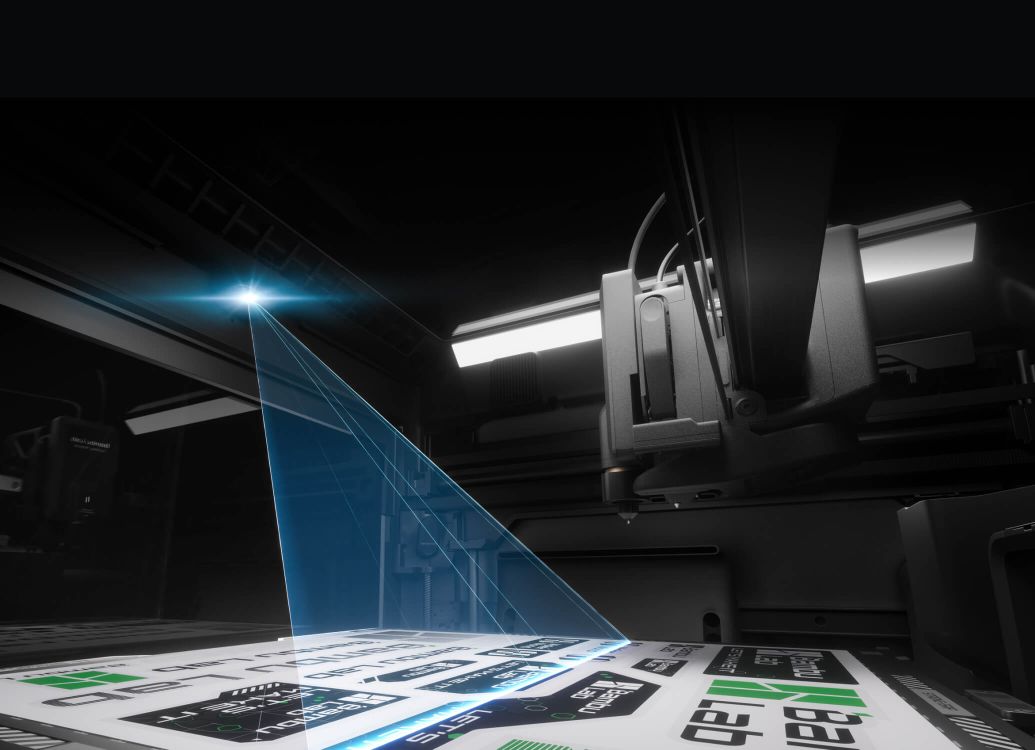

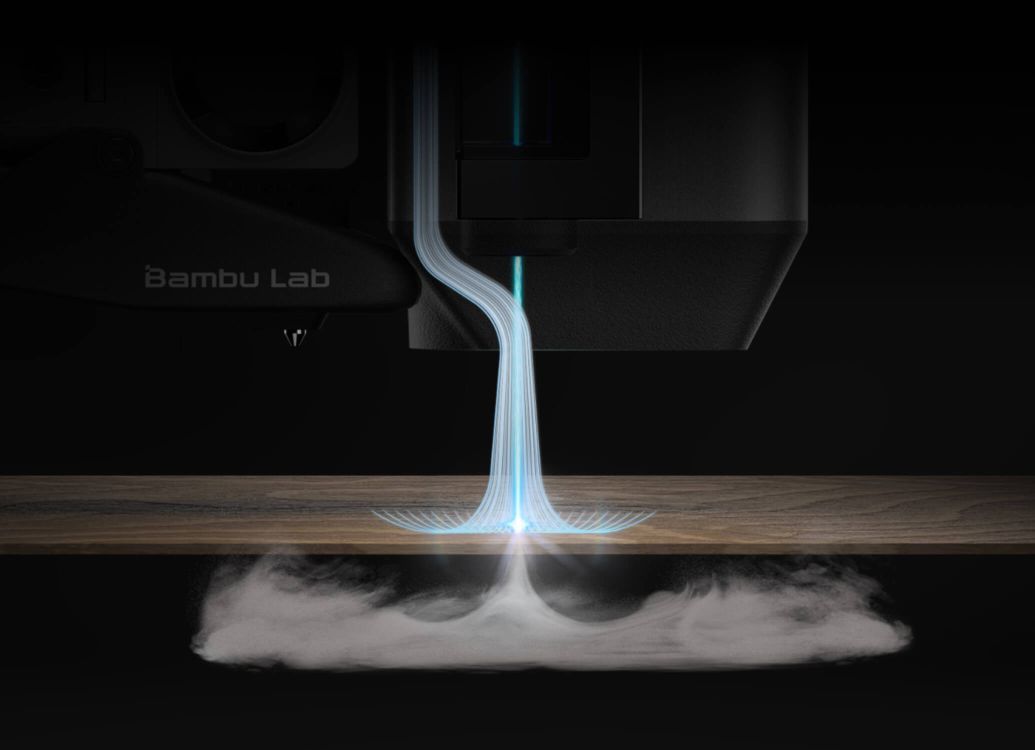

Unleash new creative possibilities with the compact, capable, and all-in-one laser functionality. The 10W 455nm laser module allows you to effortlessly cut through materials like 5 mm plywood, acrylic, or PU with precision and speed.

Features like Live Spatial Alignment, enabled by top-down BirdsEye and onboard toolhead cameras, let you preview toolpaths with 0.3 mm accuracy directly on your material.

Air Assist keeps lines crisp by blowing away smoke and char, preventing soot buildup and beam distortion.

Additionally, a digital cutting module handles paper, vinyl, and PU leatherette,

while the drawing module automates linework and sketches, all with incredible precision.

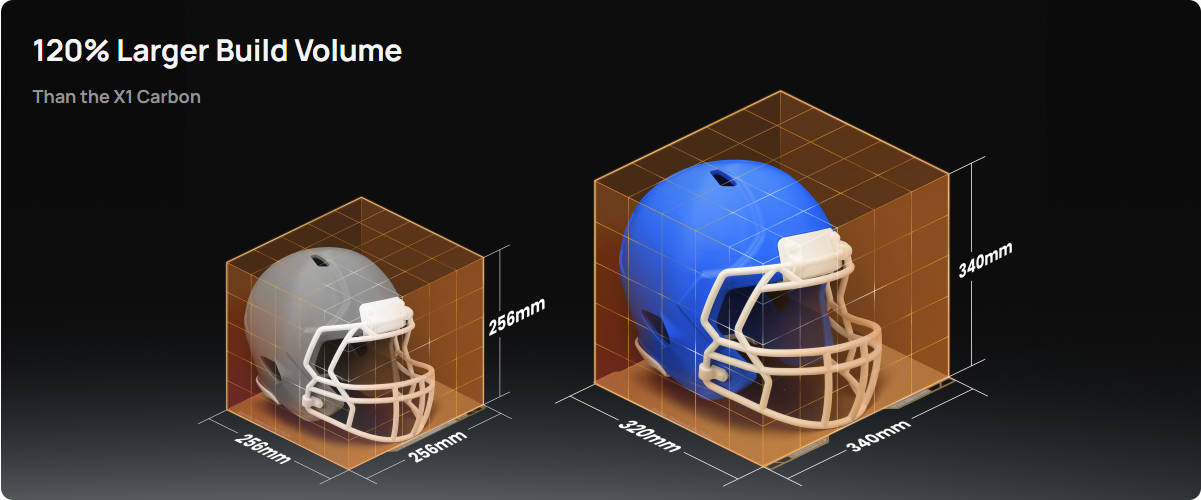

Expanded Build Volume, Uncompromised Performance

The Bambu Lab H2S Full Laser Combo offers an expansive build volume of 340×320×340 mm³, making it the largest print space among all Bambu Lab printers. This provides 120% more build volume than the X1 Carbon, allowing you to fully realize your vision in a single print, tackling bigger projects with fewer plate changes and maximizing your productivity.

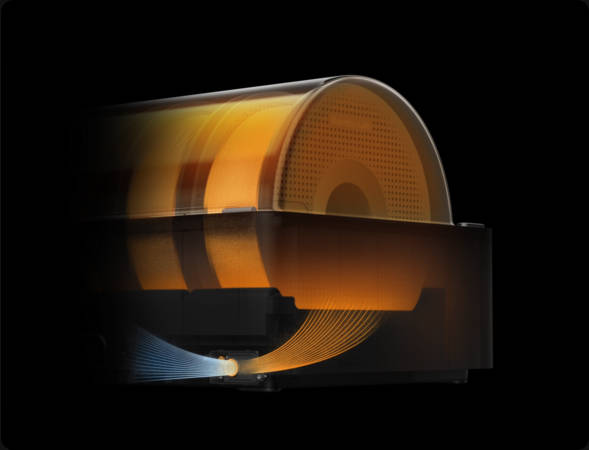

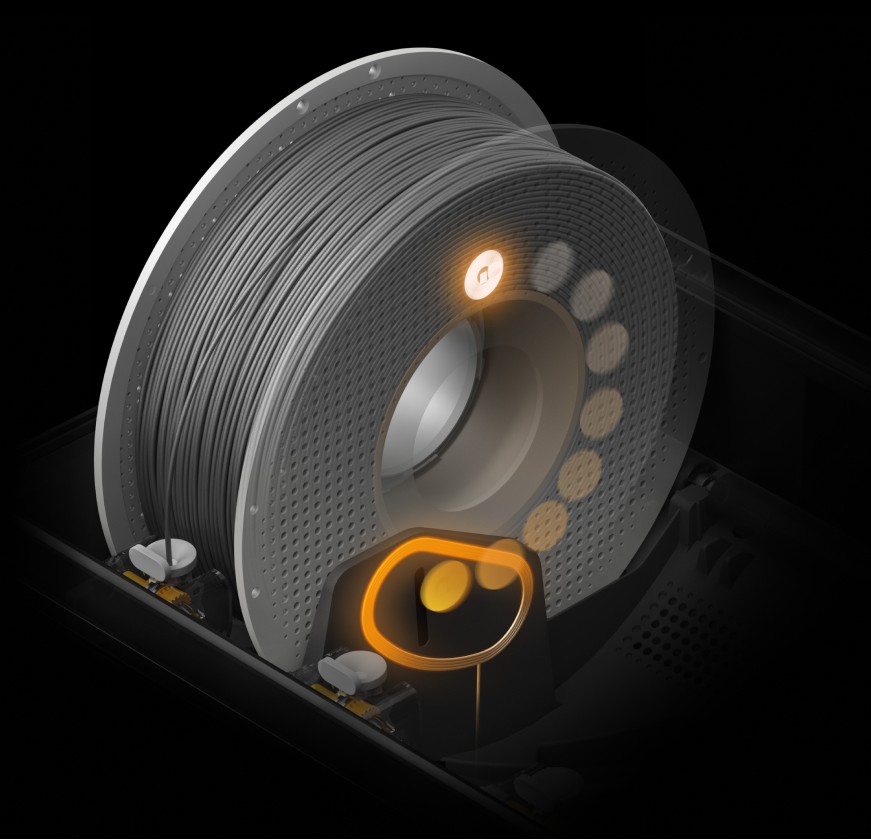

Bambu Lab AMS 2 Pro – Multi-Color & Material Mastery

The included Bambu Lab AMS 2 Pro Automatic Material System elevates your printing capabilities with multi-color and multi-material functionality.

It features active air vent 65°C filament drying, ensuring your filaments are always in optimal condition. With airtight storage and support for up to 24-color/multi-material printing, the AMS 2 Pro provides unparalleled flexibility. Its brushless servo feeding motor accelerates filament feeding by 60%, saving an average of 10 minutes per 100 filament changes.

RFID filament sync automatically matches drying settings for official Bambu filaments, and tool-free filament tube access makes maintenance simple.

Key Technical Specifications for the Bambu Lab H2S Full Laser Combo:

- Printing Technology: FDM (Fused Deposition Modeling)

- Toolhead Speed: Up to 1000 mm/s

- Nozzle Diameter: 0.4 mm

- Filament Diameter: 1.75 mm

- Max Temperature: 350 ℃

- Build Volume: 340 × 320 × 340 mm³

- Bambu Lab AMS 2 Pro - Automatic Material System: Supplied

- Filament Drying: Supported

- RFID Identification: Supported

- Active Moisture Discharge: Supported

- Temperature & Humidity Detection: Supported (Real-time display on screen, Bambu Studio, Bambu Handy)

- 10W Laser Module: Supplied

- Laser Type: Semiconductor Laser

- Engraving Area: 310*260 mm²

- Air Pump: 30 kPa, 30 L/min

- Cutting Module: Supplied

- Cutting Area: 297.5*300 mm²

- Drawing Area: 300*255 mm²

- TFT Touchscreen: 5" (720*1280)

- Sensors: Filament Run Out Sensor; Tangle Detection; Odometry Supported via AMS

- Operating System Compatibility: MacOS, Windows, Linux

- Connectivity: IEEE 802.11 a/b/g/n Wi-Fi enabled

- AIR Filtration System: Pre-filter Grade G3; HEPA Filter Grade H12

- Power: 2050 W@220 V / 1170 W@110 V

Your Partner in 3D Innovation

Elevate your capabilities with the Bambu Lab H2S Full Laser Combo. Purchase it today from 3DDevice – your trusted experts in 3D printing and scanning since 2012. We offer comprehensive consultations, personalized assistance in choosing the right equipment, and qualified support before, during, and after your purchase. Choose 3DDevice for unparalleled expertise and dedicated customer care.