- Stock: In Stock

- Product code: 00-00013660

- Shipping Weight: 41.40kg

Bambu Lab H2C Laser Full Combo 40W – Professional 3D Printer with Laser Module

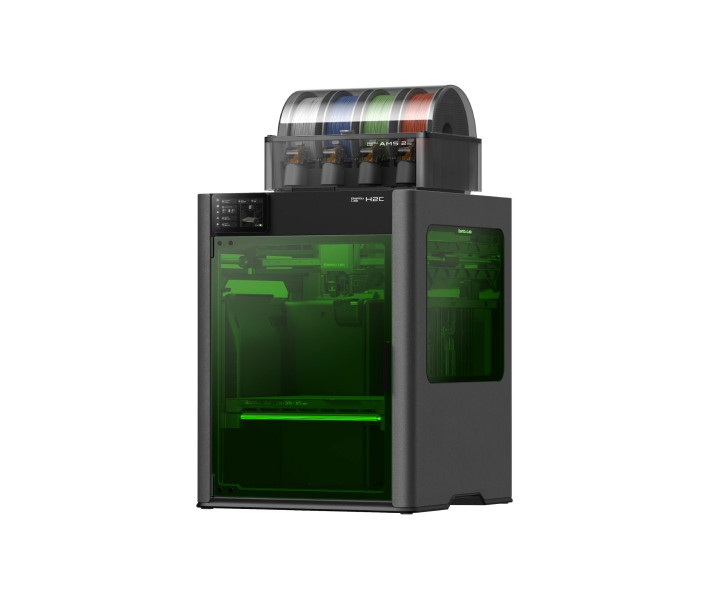

The Bambu Lab H2C Laser Full Combo 40W 3D printer is a versatile professional system combining high-precision FDM printing and powerful laser functions for engraving and cutting. The device is designed for engineers, craftsmen, designers, and manufacturing studios who require stability, multi-material capability, and maximum automation. The H2C Laser Full Combo 40W 3D printer does not take up much space, even in its maximum configuration. It's a factory that easily fits on a desk.

Key Advantages of the Bambu Lab H2C Laser Full Combo 40W

- High precision and multi-material capability

- 40W laser module for cutting and engraving

- Automatic Vortek hotend changing

- Heated chamber and bed

- Speed up to 1000 mm/s

- Intelligent control and AI monitoring

- Safe enclosed chassis made of fire-resistant materials

- Stable printing of engineering polymers and composites

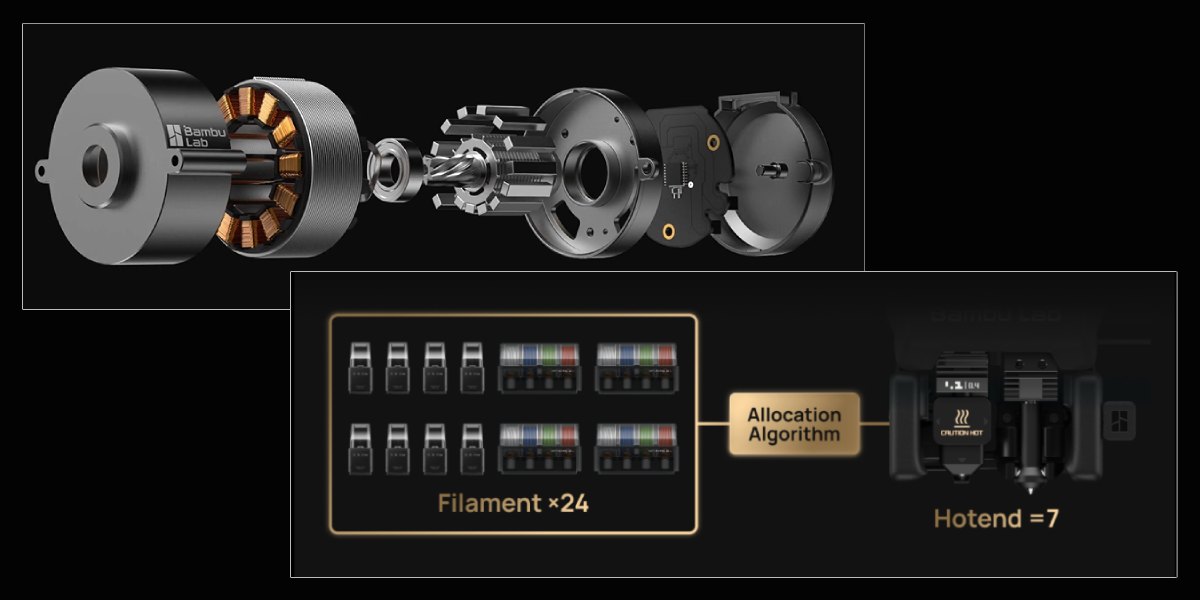

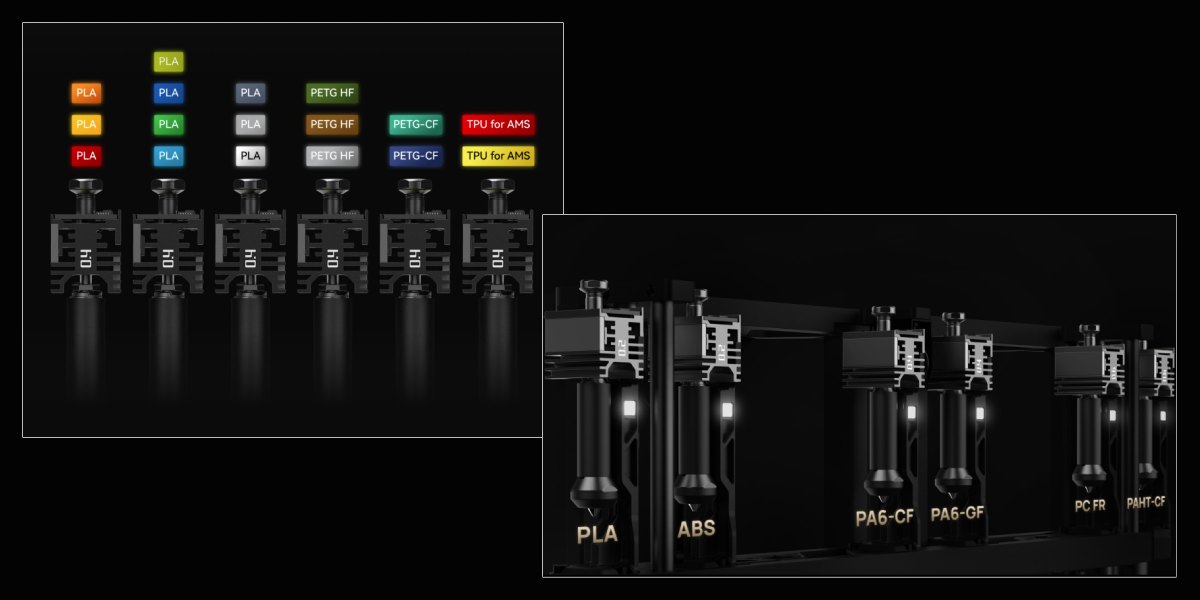

How the Vortek Hotend Change System works in combination with AMS

- The Vortek system works in conjunction with the AMS 2 Pro automatic filament feeding (and in the expanded configuration — with AMS HT), ensuring fully automatic material changing. You no longer need to manually load or switch filaments.

- Each nozzle "remembers" the last filament used on it — its color and type. Therefore, upon the next startup, the printer automatically suggests using the corresponding nozzle for the selected material, which speeds up setup and reduces the likelihood of errors.

- If printing is performed with multiple filaments (for example, when working with different colors, materials, or composites), the built-in algorithm distributes materials to the nozzles as efficiently as possible: it determines which nozzle to select for each filament to reduce waste and minimize the need for purging.

- At the same time, the printer's working volume remains virtually unchanged, despite the use of six interchangeable nozzles — as only the hotend is replaced, not the entire print head.

Advantages of the comprehensive solution

- Reduced filament consumption — eliminates the need to "purge" the nozzle when changing color or material type, as happens in traditional multi-material systems. This is especially important when working with expensive composites and engineering plastics.

- Increased speed and productivity — inductive heating in ~8 seconds, automatic nozzle changing and filament feeding, as well as intelligent material distribution significantly accelerate the multi-filament printing process.

- Simplified automation — the minimal number of manual actions reduces the probability of errors and makes working with multi-material, multi-color, and technically complex projects much easier.

- Expanded material capabilities — different types of filaments (composites, carbon fiber, flexible, or rigid plastics) can be pre-assigned to specific nozzles, reducing the risk of cross-contamination and ensuring stable feeding.

Bambu Lab 3D Printer for Professional Applications

The 3D printer is equipped with the innovative Vortek Hotend Change automatic hotend replacement system, allowing work with different nozzles and materials within a single job without stops or manual reconfiguration. This approach ensures layer accuracy, reduces the number of filament changes, and optimizes filament consumption. Support for PLA, PETG, TPU, ABS, ASA, PC, PA, and composite materials makes the device universal for production tasks.

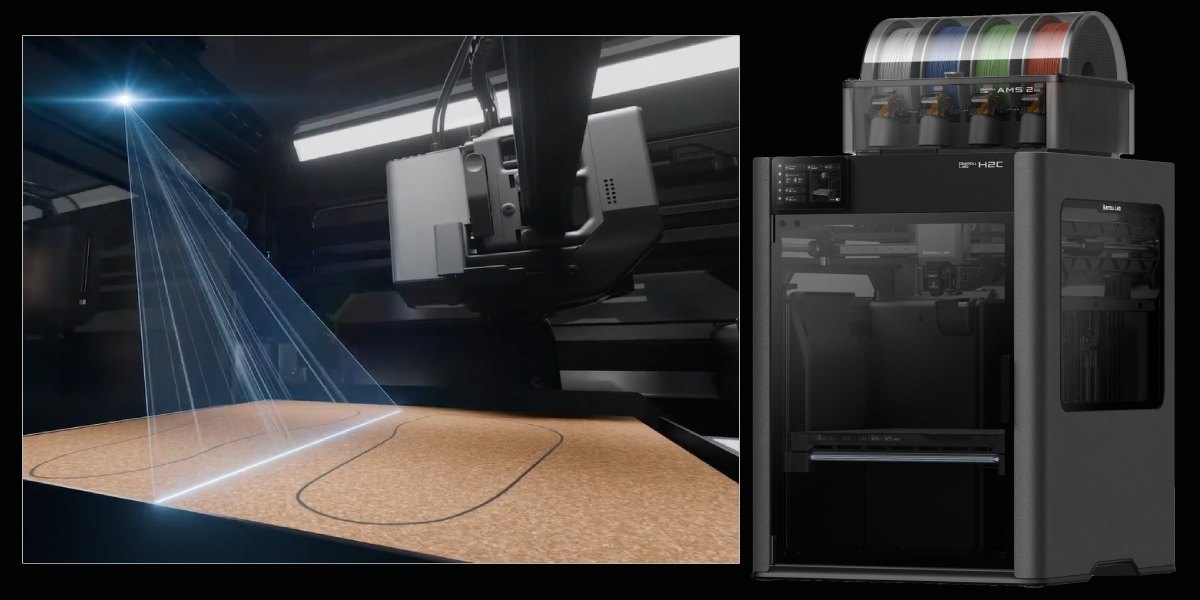

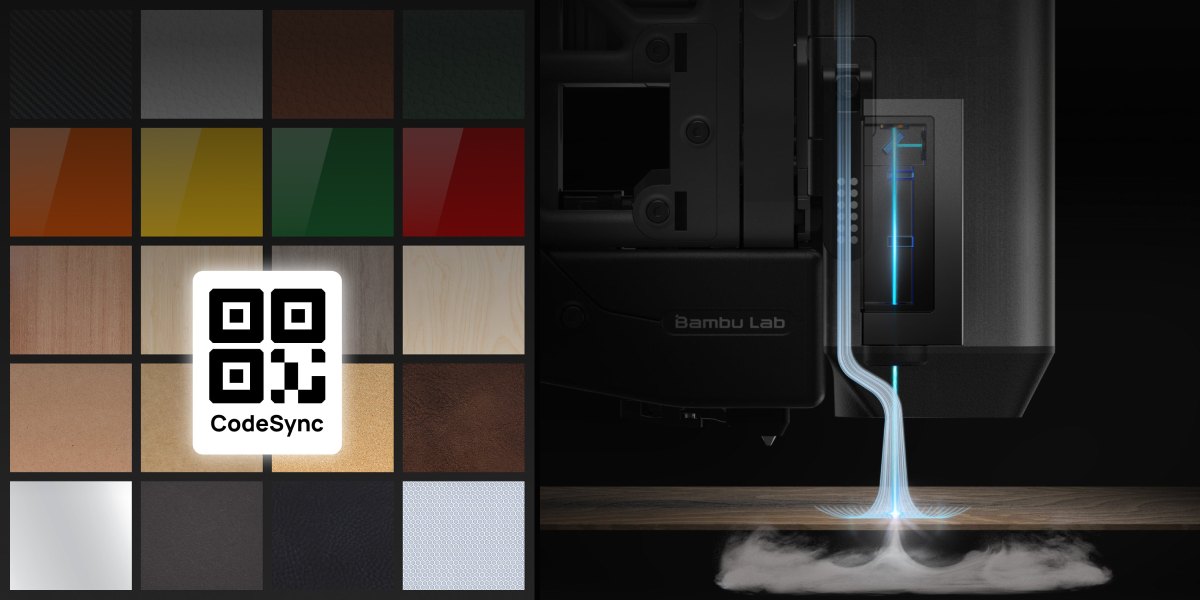

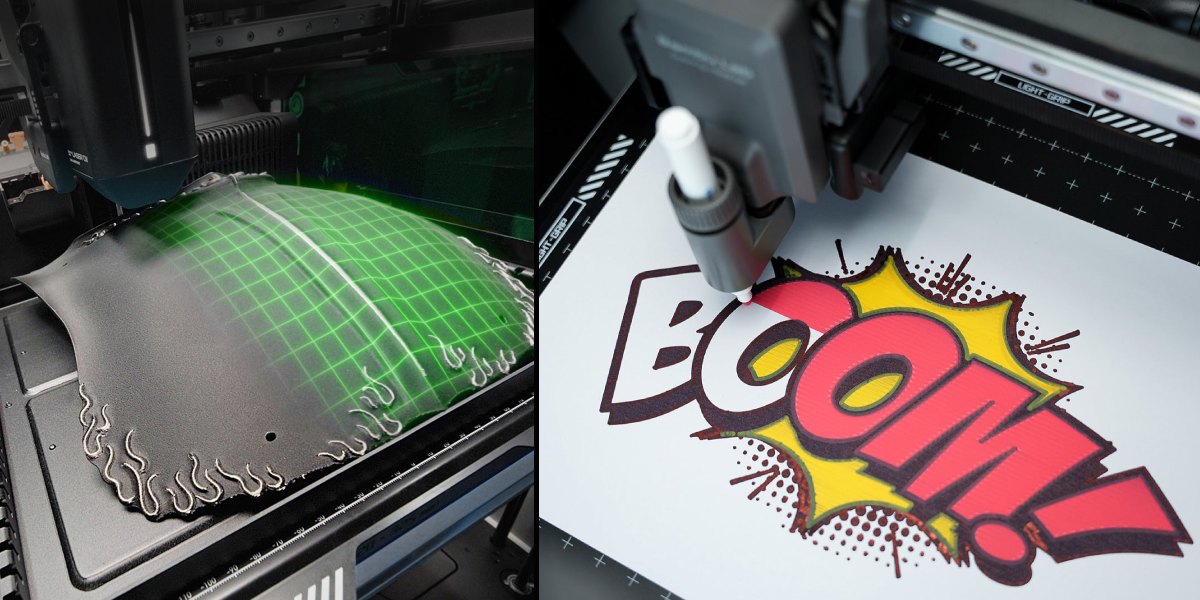

40W Laser for expanded capabilities

The 40W laser module provides engraving and cutting of wood, plywood, leather, and acrylic, and also allows for deep cuts up to 15 mm in wood. A high speed of up to 1000 mm/s and a fine working spot maintain detail even with complex trajectories. Built-in protective filters and sensors guarantee safe operation in enclosed spaces.

High precision and intelligent control system

High printing accuracy is achieved thanks to the Vision Encoder, which tracks axis movement with micron precision. Fully automatic calibration, a set of several built-in cameras (nozzle camera, tool camera, bird's eye camera), and an AI-based print monitoring system allow real-time control of the manufacturing process. The device is capable of automatically adjusting filament feeding and stopping printing upon error detection.

Thermal stability and work with engineering polymers

The high-temperature hotend (up to 350 °C), heated chamber (up to 65 °C), and bed (up to 120 °C) ensure stable printing of complex materials, including fiber-reinforced ones. The enclosed chassis made of UL94 V-0 class fire-resistant materials guarantees safety and a uniform temperature regime.

High speed and powerful extruder

The FDM system is built on a fast and stable CoreXY drive, providing movement speeds up to 1000 mm/s. The PMSM servo extruder develops a force up to 10 kg, allowing for even feeding of even rigid and filled filaments. Multi-layer items and large-sized models are printed without oscillations or material skipping.

Compatibility characteristics of the Bambu Lab 40W laser module with materials*

| Material / Blank | Recommended Tasks | Approximate Parameters* (Power / Speed / Passes) |

|---|---|---|

| Plywood / Wood (thin, ~3–6 mm) | Engraving / Cutting / Lettering / Contours | For cutting 3 mm plywood: ~ Power = 100%, speed ≈ 16 mm/s (one pass) — For engraving: reduce power, increase speed; for example, 40-60% power, speed ~ 300-600 mm/s — start testing. |

| Thick plywood / Dense wood (~6–15 mm) | Cutting, contour cutting | Maximum depth (for 40 W) — up to ~ 15 mm (for basswood plywood). May require multiple passes, slow speed, high power. |

| Dark acrylic / Painted plastic (dark, opaque) | Engraving, lettering, drawings | As a starting point: moderate–high power (e.g., 70-100%), medium speed — test. (Many laser cutting systems require manual fine-tuning.) There is no official table for all plastics. |

| Leather / Faux leather / Leather blanks | Engraving logos, ornamentation, decorative carving | The laser works well on natural/faux leather, at moderate power and speed. (Material is declared compatible.) |

| Rubber / Soft polymers (stamp gums, soft plastic) | Engraving — drawings, stamps, labels | Theoretically possible, but the result strongly depends on the rubber's composition. Start with low power + small number of passes. Tests are needed. |

| Metal sheets (brass, aluminum, stainless steel, etc.) | Marking / Engraving (not cutting) | Engraving is possible provided the surface is matte or matted (sanded, polished, sandblasted) so the laser "grips". Users on forums report success at: Power = 100%, speed ≈ 250 mm/s, 5–6 passes (for a matte aluminum tag). |

| Stone / Minerals / Tiles (thin slabs) | Engraving — text, ornaments, logos (surface) | Theoretically listed as a "supported" material. Settings: high power, slow speed, possibly many passes. Test on a small area first. |

| Cardboard / Paper / Thin cardboard / Plywood ~1–3 mm | Engraving, cutting — stencils, decor, souvenirs | Can use cutting/engraving mode; for thin materials — reduce power, increase speed, minimize the number of passes; work on small blanks and with extraction (to avoid ignition). |

* Settings are given in relative values (e.g., "power 70-100%") — because for a 40 W system, the exact absolute power value may depend on the software's "slippage"; and "speed" is the linear speed of the laser during engraving/cutting. The data in the table are indicative.

Intelligent automation and ease of management

The modern control interface includes a touch screen, Wi-Fi, LAN, and USB, allowing jobs to be launched both locally and remotely. Developer mode support provides the ability to integrate the device into production processes and remote control systems.

Extended functionality for workshops and production

The combined capabilities of 3D printing and laser cutting make the H2C Laser Full Combo 40W an optimal solution for prototyping, small-batch production, manufacturing of decor, souvenirs, functional parts, and engineering assemblies. The printer is equally effective in tasks of creating visual models, mechanical parts, stencils, packaging, structural elements, and artistic products.

Technical specifications of the Bambu Lab H2C 3D printer

| Element | Specification | |

| Printing Technology | Fused Deposition Modeling | |

| Chassis | Build Volume (W*D*H) | Single Print: 325x320x325 mm cube Dual Print: 300x320x325 mm cube Total volume for two nozzles: 350x320x325 mm cube |

| Frame and Shell | Aluminum, Steel, Plastic, and Glass | |

| Laser Safety Windows | Present in Laser Edition, standard H2D can be upgraded with Laser Upgrade Kit | |

| Air Assist Pump | Present in Laser Edition, standard H2D can be upgraded with Laser Upgrade Kit | |

| Physical Dimensions | Physical Dimensions | 492x514x626 mm cube (Package Size: 620x620x755 mm cube) |

| Weight | 31 kg (Gross: H2D: 38.5 kg; H2D AMS Combo: 42.3 kg; H2D Laser Full Combo: 46.2 kg) |

|

| Print Head | Hotend | All-Metal |

| Geared Extruder | Hardened Steel | |

| Nozzle | Hardened Steel | |

| Max Nozzle Temperature | 350 degrees Celsius | |

| Installed Nozzle Diameter | 0.4 mm | |

| Supported Nozzle Diameters | 0.2 mm, 0.4 mm, 0.6 mm, 0.8 mm | |

Additional information about Bambu Lab H2C

- All presented data on printing time and purging consumption are calculated by Bambu Studio.

- The stated characteristics and advantages of Vortek are based on the full use of 6 inductive hotends and corresponding AMS units.

- All data about the H2C product are based on internal tests by Bambu Lab. Actual results may vary depending on individual product characteristics, user habits, and environmental conditions. Refer to the actual usage data for reference.

- An additional video encoder is required to enhance movement accuracy.

- Automatic hole contour compensation must be enabled in Bambu Studio, and the specified Bambu filament must be used.

- The DynaSense extruder filament grinding feature is limited by the filament type.

- "59 sensors" refers to the fully equipped H2C Laser Edition with the Bird's Eye Camera and 6 inductive hotends.

- High-flow hotends are optional equipment purchased in the official store.

- In accordance with the safety protocol, developer mode cannot be enabled when using laser and cutting functions.

- Push notifications require the use of Bambu Handy and connection to the cloud.

- Creator projects are provided for illustrative purposes only. Bambu Lab does not endorse or make any representations or warranties regarding creator projects, including but not limited to the safety, competitiveness, or usability of any 3D-printed works based on such projects. See our Terms of Service for more details.

- The 8-second inductive hotend heating time is calculated based on the base printing temperature of Bambu PLA.

- The "no purging" statement does not include the initial purge required when loading a new filament into the hotend.

- The fire-resistant chamber is made of UL94 V-0 class materials.