- Stock: In Stock

- Product code: 00-00013659

- Shipping Weight: 53.00kg

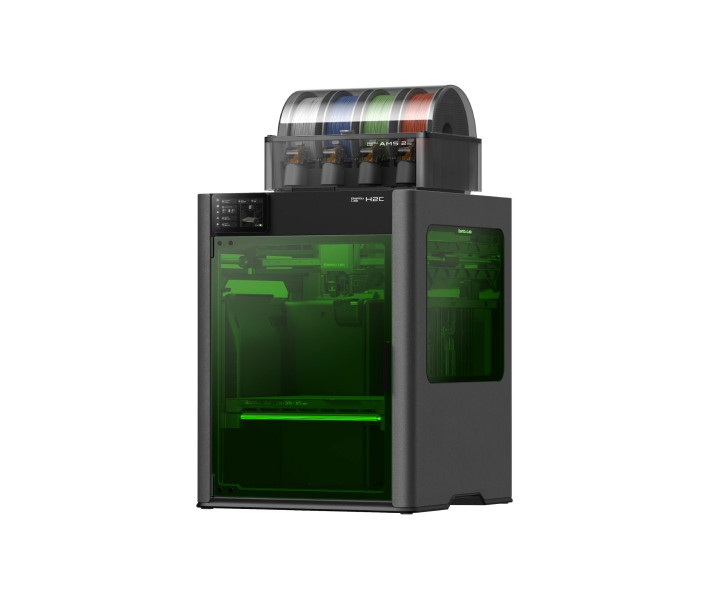

Bambu Lab H2C Laser Full Combo 10W – Desktop Factory for 3D Printing, Engraving, and Cutting

Bambu Lab H2C Laser Full Combo 10W is a set including a 3D printer, a laser engraver, and an AMS. The set allows for maximum multifunctionality in one device. This specialized version of the flagship H2C printer is a comprehensive desktop station, combining the advanced capabilities of high-speed multi-material FDM printing with the functionality of a powerful laser system. The printer is designed for professionals who require the highest flexibility, precision accuracy, and maximum automation in prototyping and small-batch production processes.

This kit is the ideal choice for engineering firms, R&D departments, design studios, and small-scale manufacturing facilities that require rapid task switching: from printing high-temperature polymers to precise laser processing.

H2C Full Combo Configuration and Versatile Positioning

Composition of the Laser Full Combo 10W Kit*

The "Laser Full Combo (10W)" configuration includes everything necessary to start working with 3D printing and laser processing:

- Bambu Lab H2C Printer.

- A 10 W laser module, which transforms the printer into a powerful engraver and cutter.

- One AMS 2 Pro module for automatic filament feeding, a key element for multi-spool printing.

- Nozzle modules (hotends): Several right (inductive) hotends (including spares, with 0.4 mm nozzle diameters, as well as 0.2 mm and 0.6 mm, depending on the package), and two left (standard) hotends (with a 0.4 mm diameter).

- Accessories for maintenance, laser module installation, cables, and documentation.

*The manufacturer may change the configuration without prior notice. Please check the exact contents of the box with your manager during order confirmation.

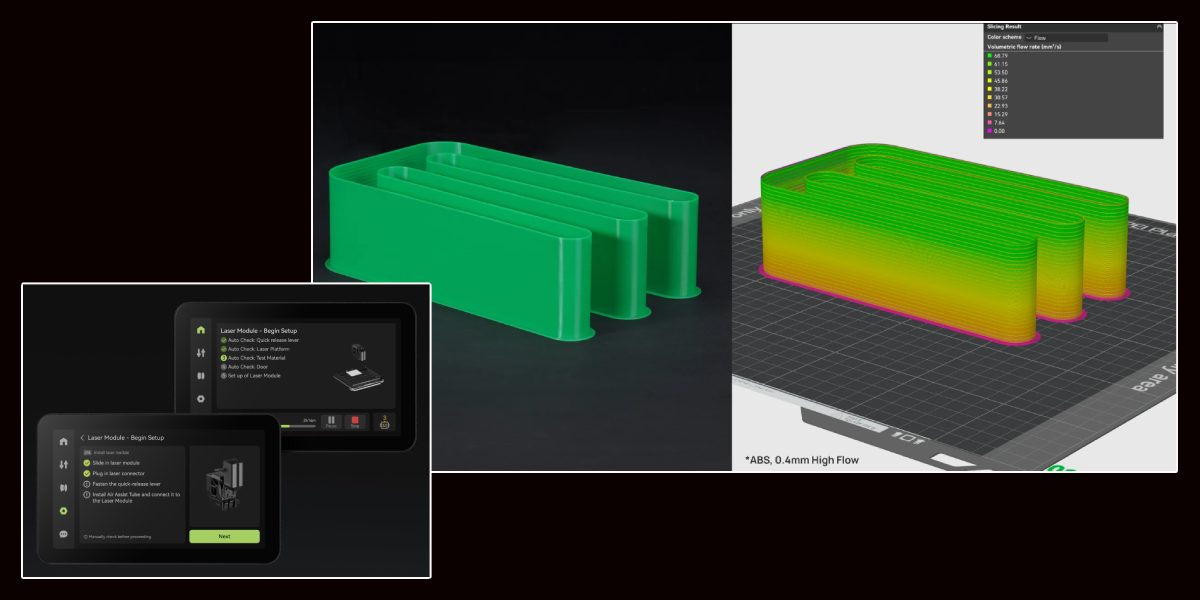

"3-in-1" Versatility on a High-Speed Platform

Bambu Lab H2C in this configuration offers the user a unique combination of:

- High-Speed FDM Printing: thanks to CoreXY kinematics and the Vortek system.

- Multi-Material and Multi-Color Printing: via the AMS 2 Pro system and multi-nozzle configuration.

- Powerful Laser Engraving and Cutting: with the 10 W laser module.

The printer's dimensions are approximately 492 × 514 × 626 mm (width × depth × height) with a mass of about 32.5 kg, making it a powerful yet compact solution for desktop use. Energy consumption reaches 1800 W at 220 V (depending on the region).

Innovative Architecture for Printing and Materials Science

Print Area Volume and Configuration

The high-precision Bambu Lab H2C 3D printer features an adaptable print volume, which depends on the mode used:

- In single-nozzle mode (left): 325 × 320 × 325 mm.

- In single-nozzle mode (right): 305 × 320 × 325 mm.

- In dual-nozzle mode or other modes: up to 330 × 320 × 325 mm.

It is important to note that the presence of the Vortek system on the right side of the chamber slightly limits the available working space on the X-axis when using the right nozzle or in dual printing mode.

Working with Engineering and Technical Materials

The Bambu Lab H2C is built to work with the widest range of filaments, including: PLA, PETG, ABS, PA (Nylon), PC (Polycarbonate), PPA, and others.

The maximum nozzle temperature of up to 350 °C allows for successful work with demanding technical and high-temperature polymers, which are critically important for creating functional prototypes and parts.

The enclosed chamber helps to maintain stable temperature, which is a key condition for printing materials like ABS and PC, preventing warping and shrinkage.

Thanks to the AMS 2 Pro system, multi-spool printing is possible, which, combined with the high nozzle temperature, allows for the creation of complex composite parts.

Key Technologies: Vortek and AMS 2 Pro

Vortek Hotend Change System – Fast Nozzle Change by Bambu Lab

- The Vortek Hotend Change System significantly increases the efficiency of multi-material printing. It is a modular heater system based on:

- Inductive heating: allows nozzles to reach working temperature in a record short time.

- Magnetic attachment: ensures quick and precise replacement of nozzles without the need for complex manual setup.

- Multi-nozzle capability (up to seven heating modules) in combination with Vortek provides incredible flexibility, allowing for rapid switching between different materials, colors, or nozzles of various diameters (0.2 mm, 0.4 mm, 0.6 mm). The simplicity and speed of maintenance significantly reduce downtime between production cycles.

AMS 2 Pro: Automatic Material Feeding

- The AMS 2 Pro system provides automatic filament feeding from multiple spools. This allows for:

- Multi-color printing without operator intervention.

- The use of auxiliary materials (e.g., soluble supports) in a single job.

- Reliable printing with fragile or moisture-sensitive materials thanks to a controlled storage environment.

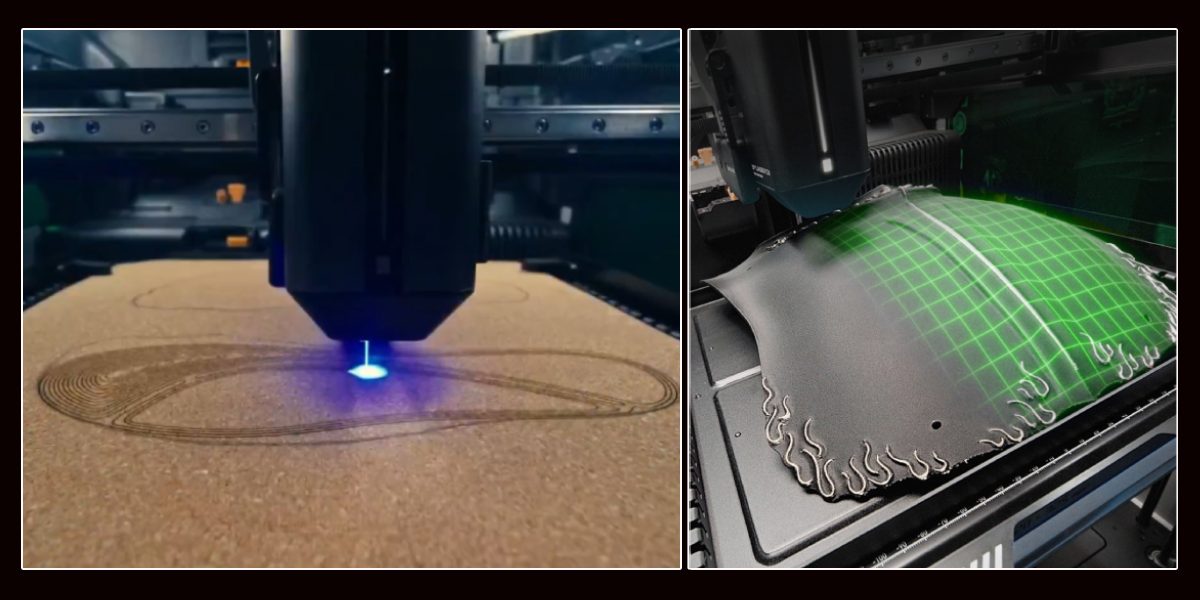

10W Laser Module Functionality and Safety

The 10 W laser power opens up new possibilities for working with flat materials.

10 W Laser Module: Engraving and Cutting

- High-speed engraving with this module reaches speeds of about 400 mm/s (depends on the material and settings).

- Material cutting: with optimal parameters, the laser can cut thin sheets of materials, such as plywood or balsa, up to 5 mm thick (depends on density).

- Laser type: The laser module's wavelength is approximately 455 nm.

Safety During Operation (Class 4)

- Mandatory adherence to safety measures when working with a Class 4 laser module:

- Protective eyewear must be used.

- An exhaust fan or local ventilation system is highly recommended to remove smoke and harmful particles generated when cutting wood, plastic, and other materials.

- Adherence to the manufacturer's safety instructions for installation and operation is critically important.

Integration and Performance of the H2C Laser Full Combo 10W

Bambu Lab Ecosystem

- The intelligent Bambu Lab H2C 3D printer is fully integrated into the manufacturer's digital ecosystem.

- Software: full compatibility with Bambu Studio (slicer) and the Bambu Handy mobile app for remote control.

- Network Interaction: Wi-Fi support, built-in cameras, and sensors ensure continuous monitoring and diagnostics of the printing process.

The printer can operate very fast, reaching hundreds of millimeters per second in high-speed motion modes, which, combined with fast nozzle changes (Vortek) and automatic filament feeding (AMS 2 Pro), provides outstanding throughput for complex prototyping.

The Bambu Lab H2C Laser Full Combo 10W is an investment in manufacturing flexibility and speed. Appreciate all the advantages of this desktop factory, which, thanks to the combination of FDM, multi-material capability, and laser processing, allows you to implement the most complex engineering and design projects as quickly as possible, ensuring high precision and minimal operating costs. Call us – our experienced managers will help you choose a 3D printer for any task.

Technical Specifications of the Bambu Lab H2C 3D Printer

| Element | Specification | |

| Printing Technology | Fused Deposition Modeling | |

| Enclosure | Build Volume (W*D*H) | Single Print: 325x320x325 mm cube Dual Print: 300x320x325 mm cube Total Volume for Dual Nozzles: 350x320x325 mm cube |

| Frame and Shell | Aluminum, Steel, Plastic, and Glass | |

| Laser Safety Windows | Present in Laser Edition, standard H2D can be upgraded with Laser Upgrade Kit | |

| Air Assist Pump | Present in Laser Edition, standard H2D can be upgraded with Laser Upgrade Kit | |

| Physical Dimensions | Physical Dimensions | 492x514x626 mm cube (Package Size: 620x620x755 mm cube) |

| Mass | 31 kg (Gross: H2D: 38.5 kg; H2D AMS Combo: 42.3 kg; H2D Laser Full Combo: 46.2 kg) | |

| Print Head | Hotend | All-Metal |

| Geared Extruder | Hardened Steel | |

| Nozzle | Hardened Steel | |

| Maximum Nozzle Temperature | 350 degrees Celsius | |

| Installed Nozzle Diameter | 0.4 mm | |

| Supported Nozzle Diameters | 0.2 mm, 0.4 mm, 0.6 mm, 0.8 mm | |

Additional Information about Bambu Lab H2C

- All presented data on print time and purge consumption are calculated by Bambu Studio.

- The claimed features and benefits of Vortek are based on the full utilization of 6 inductive hotends and corresponding AMS units.

- All H2C product data is based on Bambu Lab's internal testing. Actual results may vary depending on individual product characteristics, user habits, and environmental conditions. Refer to actual usage data for reference.

- An additional video encoder is required for enhanced motion accuracy.

- Automatic hole contour compensation must be enabled in Bambu Studio, and the specified Bambu filament must be used.

- The DynaSense extruder filament grinding function is limited by filament type.

- "59 sensors" refers to the fully equipped H2C Laser Edition with the Bird's Eye camera and 6 inductive hotends.

- High-flow hotends are optional equipment purchased from the official store.

- In accordance with the security protocol, developer mode cannot be enabled when using laser and cutting functions.

- Push notifications require the use of Bambu Handy and a cloud connection.

- Creator projects are provided for illustrative purposes only. Bambu Lab does not endorse or make any representations or warranties regarding creator projects, including but not limited to the safety, competitiveness, or usability of any 3D printed works based on such projects. See our Terms of Service for details.

- The 8-second heating time for the inductive hotend is calculated based on the base printing temperature of Bambu PLA.

- The "no purging" claim does not include the initial purge required when loading new filament into the hotend.

- The fire-retardant chamber is made of UL94 V-0 class materials.