- Stock: In Stock

- Product code: 00-00013658

- Shipping Weight: 41.40kg

Bambu Lab H2C Combo: 3D Printing Multicolor Parts in One Load

The Bambu Lab H2C Combo 3D printer is the latest flagship in the H-series lineup. It offers a perfect balance of high-precision engineering printing and advanced multicolor automation.

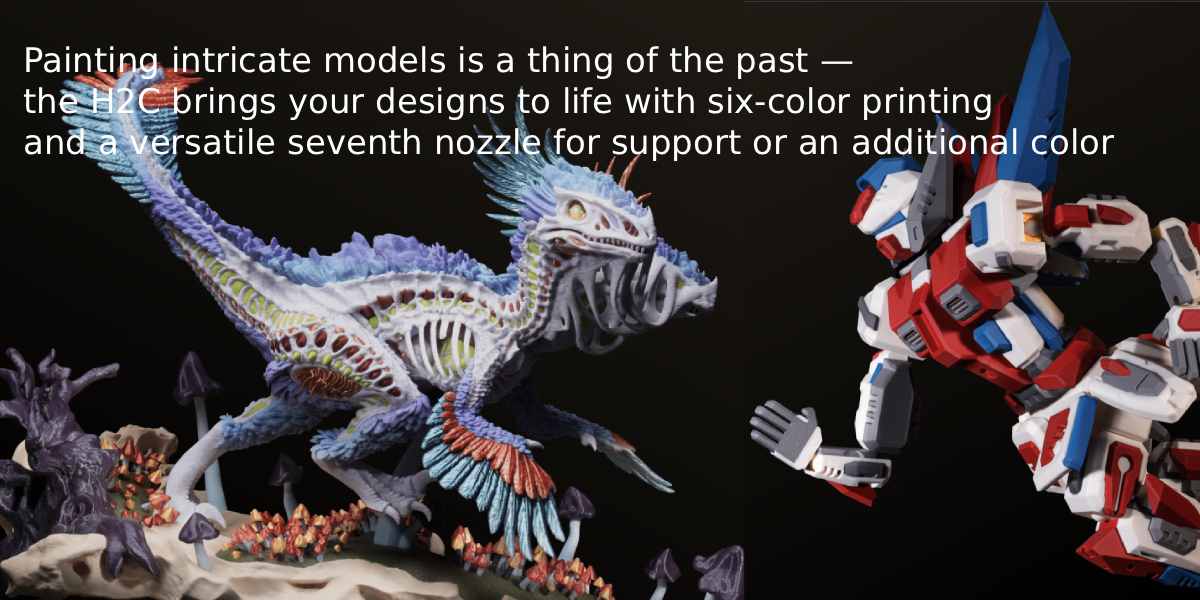

Coloring or assembling multicolor complex parts is a thing of the past. Print the product from start to finish in multiple colors without stopping to change filament and clean nozzles. You can print with up to 7 different materials without the need for nozzle purging, with minimal waste. With the advent of the H2C, multi-material printing of an entire part is no longer a dream – order the Bambu Lab H2C and start printing.

Features of the Bambu Lab H2C 3D Printer

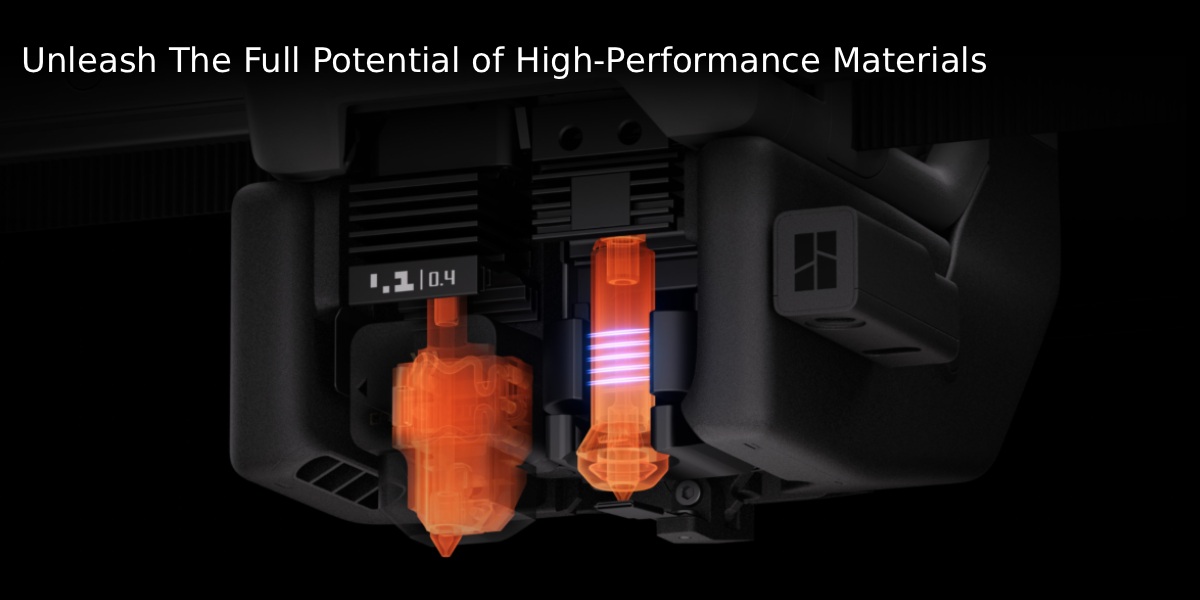

- The patented Vortek Hotend Change system supports up to six interchangeable nozzles.

- Fully automatic filament replacement, specialized hotends for specific filaments.

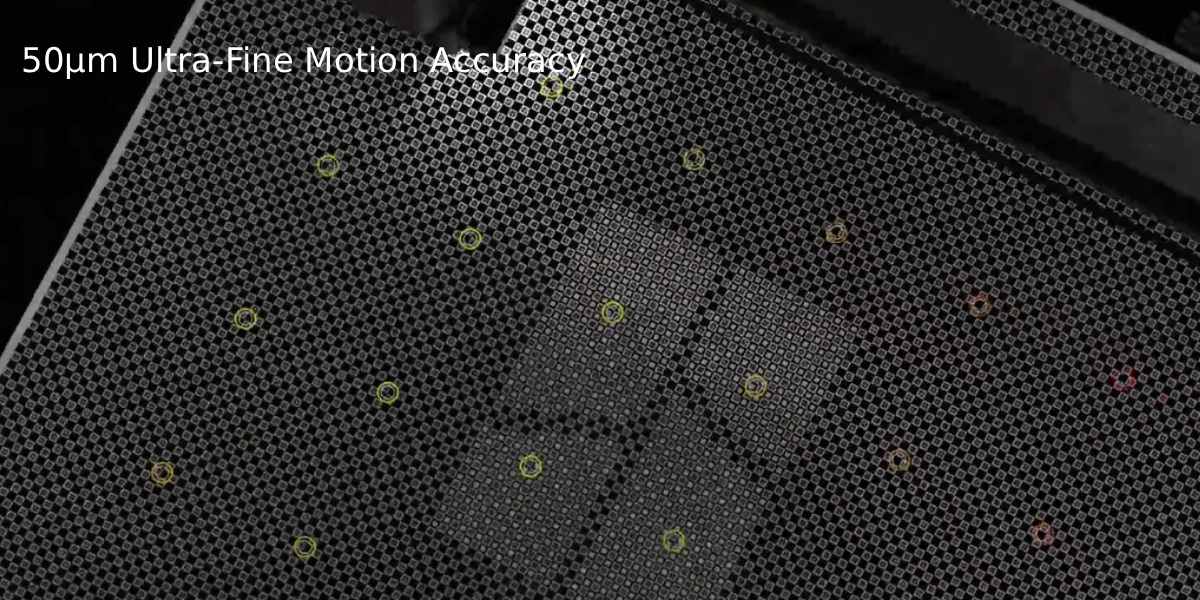

- Fully automatic nozzle offset calibration: movement accuracy of 50 microns.

- 59 sensors read parameters and transmit parameters for settings correction.

- The device can be optimized for printing up to seven colors simultaneously without unnecessary material waste.

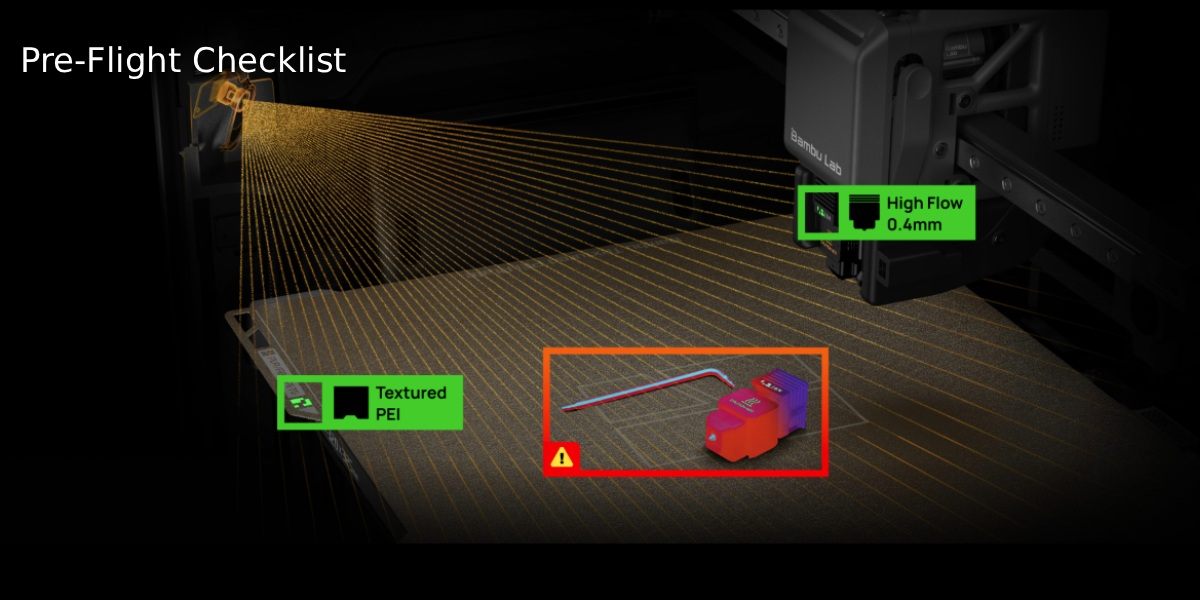

- Full pre-print check, scanning the print surface for debris at each start.

- When connected to the AMS system, the number of filaments can reach 24.

- Contactless communication, memory of each hotend.

- Precise and fast (8 seconds) inductive nozzle heating.

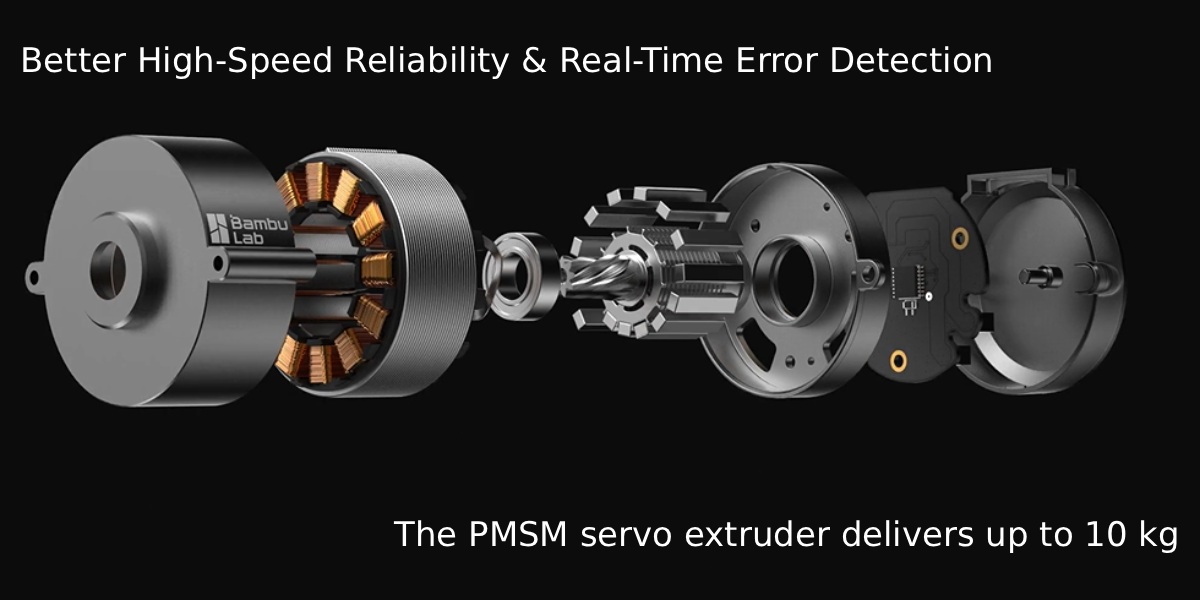

- Closed-loop servo extruder.

- Build volume of 330*320*325 mm³.

- Error detection throughout the filament path using real-time AI.

- Nozzle heating up to 350°C.

- Active chamber heating up to 65°C.

- Additional laser and cutting module with 10W/40W power.

To make the most of the H2C, you will need at least two 4-slot AMS modules and six corresponding inductive hotends. The Ultimate Set includes these modules, as well as additional hotends for expanded capabilities.

Main Characteristics and Features of the H2C

Vortek System — Innovation in Multicolor Printing

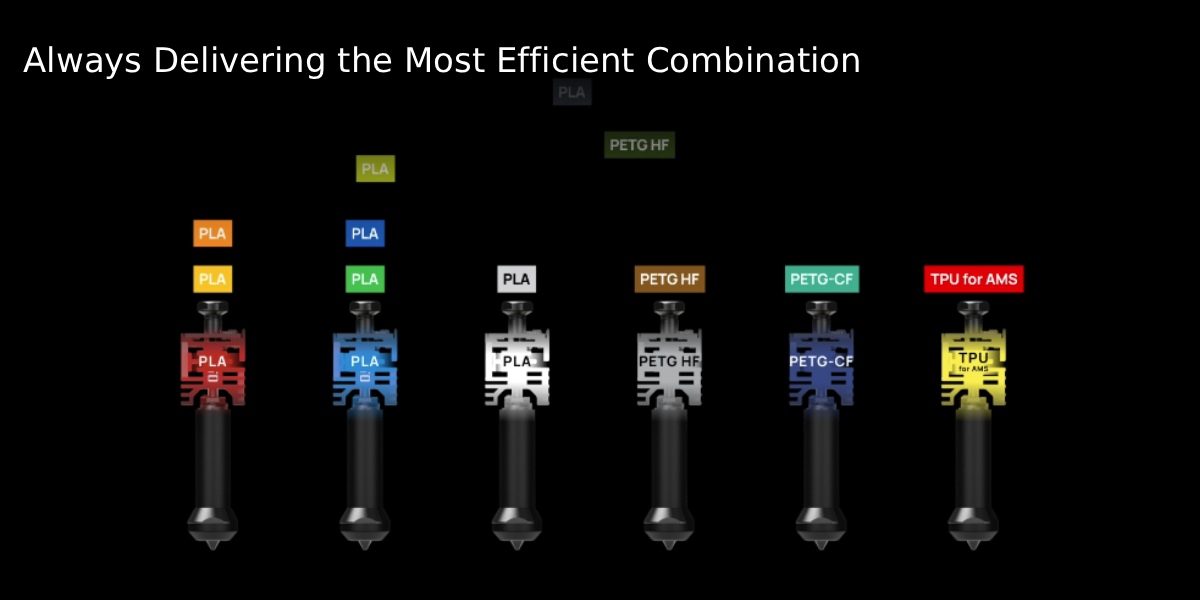

The operating principle is based on automatic nozzle change: the right part of the extruder can robotically switch up to six magnetically attached interchangeable nozzles, each identified by an embedded chip.

This architecture means that each nozzle can be "linked" to a specific filament, significantly reducing or completely eliminating the need for purging, especially when using up to seven colors.

Thanks to this, material losses are minimal, and printing remains fast — the system itself determines which nozzle was previously associated with the given filament and suggests reusing it.

Intelligence and Memory of Nozzles

- Each interchangeable nozzle has built-in memory that stores information about the last used filament.

- When starting a new task, the printer itself suggests using already familiar nozzle–filament combinations, reducing the likelihood of errors and saving time on setup.

- The nozzle calibration system is contactless, which reduces wear and simplifies maintenance.

Performance and Precision

- The extruder's servo motor (PMSM) can develop an extrusion force of up to 10 kg, which is about 70% more than stepper motors — this ensures stable filament feeding, especially at high printing speeds.

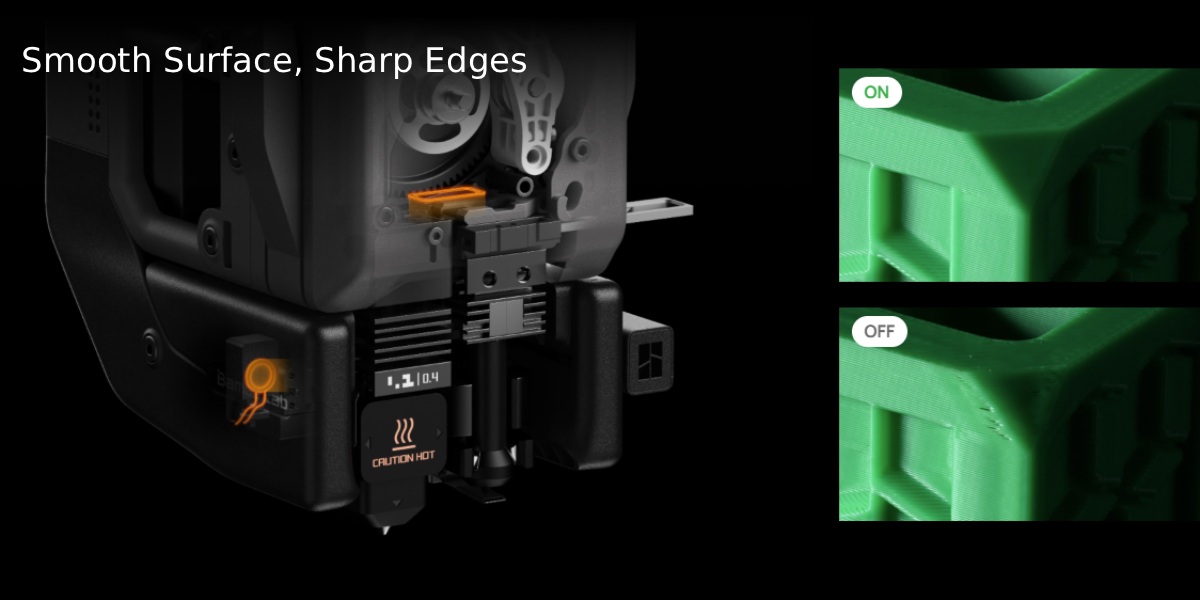

- The Vision Encoder system provides movement accuracy of less than 50 micrometers, ensuring high repeatability and minimal mechanical deviations.

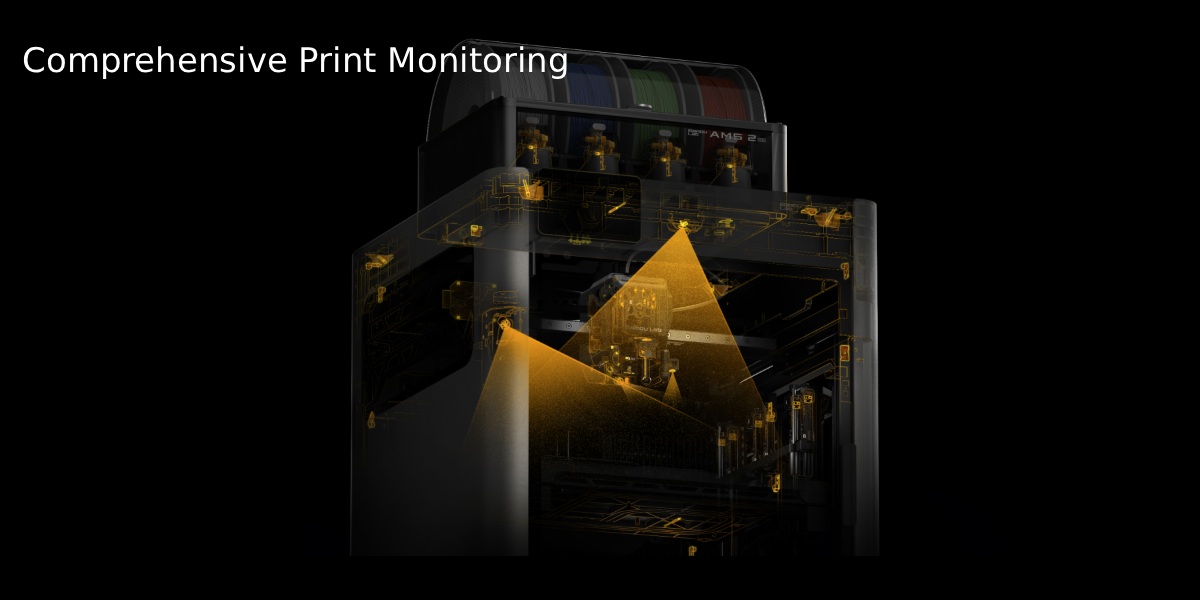

- Cameras and sensors: the printer is equipped with a machine vision system — Live View camera, nozzle camera, BirdsEye camera — together they detect possible defects in real-time.

Temperature Modes and Safety

- Maximum nozzle temperature — 350 °C, which opens up the possibility of using high-temperature engineering materials.

- The build-plate heats up to 120 °C, and the printer chamber can heat up to 65 °C, which is important for minimizing warping when printing with technical plastics.

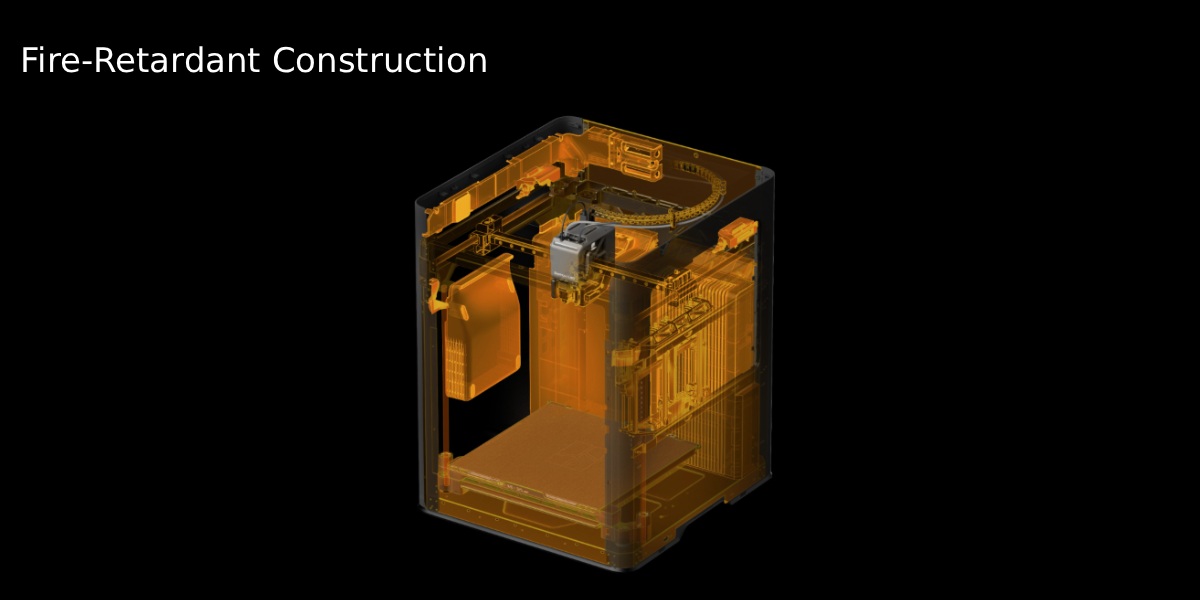

- The body is made of fire-resistant materials, and the ventilation system includes a three-stage filter: G3 pre-filter, HEPA H12, and activated carbon — to remove harmful particles and odors when working with aggressive materials.

Speed and Stability

- The maximum printing speed can reach 1000 mm/s, with acceleration up to 20,000 mm/s², making the H2C a very fast machine without compromising quality.

- Maximum filament flow — up to 40 mm³/s for test parameters (example: cylinder Ø250 mm, ABS at 280 °C).

- The cooling system is closed-loop, both for part cooling and for hotend and electronics cooling, which increases stability during long and resource-intensive tasks.

Autonomy and Diagnostics

- The device is equipped with 59 sensors and four cameras, controlled by a neural algorithm: during printing, intelligent monitoring, diagnostics, and deviation warnings are performed.

- There is a power-loss recovery function, as well as filament run-out and filament tangle sensors.

- Calibration is performed without physical contact, which simplifies maintenance and prolongs the working unit's resource.

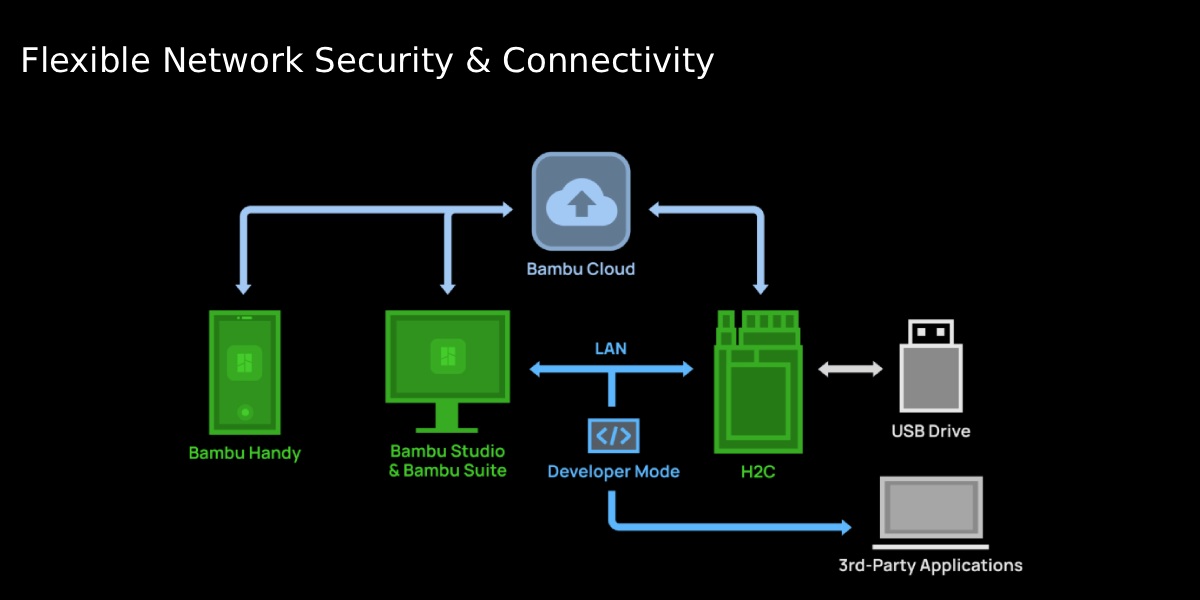

Connectivity and Control

- The printer supports Wi-Fi, LAN, as well as output from USB or built-in memory (built-in eMMC 8 GB), allowing convenient work with print files.

- Control is carried out via a 5-inch touchscreen (720×1280), a PC application, or a mobile app and the proprietary Bambu Studio slicer.

- The filament distribution algorithm in Bambu Studio automatically suggests optimal filament placement across nozzles, minimizing waste and maximizing the capabilities of Vortek / AMS.

Modularity and Expandability

- The H2C is compatible with AMS: when connecting AMS (Automatic Material System), it is possible to scale up to 24 filaments.

- Additional modules can be installed: laser (10W or 40W) for engraving and cutting, turning the printer into a versatile platform for creativity.

- Important! Note that according to the safety protocol, the developer mode cannot be enabled when using laser and cutting functions.

- For those who already have an H2D, Bambu Lab declares an upgrade path to H2C (head replacement, assembly).

Conditions for Achieving High Performance with Bambu Lab H2C

To unlock the full potential of the Bambu Lab H2C, it is important to pay attention to optimal usage conditions:

- Proper filament configuration — especially if using the AMS system: the choice of filament and nozzle combination significantly affects the efficiency of the distribution algorithm and minimizes losses. The Bambu Studio algorithm helps optimally distribute filaments among hotends.

- Calibration and alignment — thanks to contactless calibration, the tool head aligns automatically, but it is important to maintain cleanliness and stability of the platform, especially when changing nozzles.

- Temperature parameters — for high-temperature engineering materials, a chamber with active heating up to 65 °C and a build-plate up to 120 °C are used. These modes must be set correctly to avoid warping and ensure good adhesion.

- Air filtration quality — when printing with aggressive/technical plastics, it is important to use a filtration system (HEPA + activated carbon) to minimize odors and harmful particles.

- Maintenance and sensor check — regular checking of the condition of cameras, sensors, and nozzle change mechanisms allows maintaining stable print quality and reliability.

- Firmware and software — updating Bambu Studio and the printer's built-in software ensures optimal operation of the filament distribution and nozzle change algorithm.

- By fulfilling these conditions, the printer will reveal its full potential as a multicolor, multi-material, highly accurate 3D printer ready for professional and advanced tasks.

Applications

Thanks to the unique properties of the Bambu Lab H2C, it can be effectively used in the following areas:

- Prototyping and design — multicolor printing up to 7 colors without losses allows creating complex visual prototypes, mock-ups, and functional models.

- Small production and workshops — the combination of high speed, stability, and multi-filament capability makes it ideal for serial printing of small batches of products.

- Engineering and testing — the ability to work with high-temperature engineering plastics (ABS, PC, PA, etc.) allows creating functional parts, testing the strength of connections, and the geometry of complex structures.

- Education and research laboratories — thanks to automatic nozzle change and intuitive control, the printer is easy to use for educational projects, material research, and multi-filament printing.

- Cosplay, art studios, and decorative elements — seven-color printing opens up new possibilities for creating bright, complex figurines, decorations, art panels, and decorative items.

- Engraving and cutting (when installing a laser module) — the optional laser (10W or 40W) adds cutting and engraving functions, turning the H2C into a universal tool for laser engraving, cutting, and artistic work.

Uniqueness and Innovation

The Bambu Lab H2C is not just another 3D printer — it is a breakthrough platform that combines industrial precision with elegant multicolor and automation. The Vortek system, nozzle memory, loss minimization, high speed, servo reliability, and intelligent control — all of this makes the H2C one of the most advanced desktop 3D printers for creators, engineers, and professionals.

Choose a multicolor 3D printer that can handle multicolor and multi-material printing at the level of industrial equipment today. Act, and tomorrow you will already be several steps ahead of your competitors. After all, the Bambu Lab H2C is a compact and relatively inexpensive 3D printer, yet in terms of functionality and reliability, it is not inferior to industrial equipment. We invite you to get to know this device better, evaluate its capabilities, and take a step towards a new quality of 3D printing — call us!

Video of multicolor printing on Bambu Lab H2C

Additional Information about Bambu Lab H2C

- All presented data on printing time and purging consumption are calculated by Bambu Studio.

- The stated characteristics and advantages of Vortek are based on the full use of 6 inductive hotends and corresponding AMS blocks.

- All data on the H2C product is based on internal Bambu Lab tests. Actual results may vary depending on individual product features, user habits, and environmental conditions. For reference, see actual usage data.

- Additional video encoder is required to increase movement accuracy.

- Automatic hole contour compensation must be enabled in Bambu Studio, and the specified Bambu filament must be used.

- The DynaSense extruder filament grinding function is limited by the type of filament.

- "59 sensors" refers to the fully equipped H2C Laser Edition version with Bird's Eye camera and 6 inductive hotends.

- High-flow hotends are optional equipment available in the official store.

- According to the safety protocol, developer mode cannot be enabled when using laser and cutting functions.

- Push notifications require the use of Bambu Handy and cloud connection.

- Author projects are provided for illustrative purposes only. Bambu Lab does not endorse or make any representations or warranties regarding author projects, including, but not limited to, the safety, competitiveness, or usability of any 3D-printed works based on such projects. See our Terms of Service for more details.

- The 8-second inductive hotend heating time is calculated based on the basic Bambu PLA printing temperature.

- The "no purge" statement does not include the initial purge required when loading new filament into the hotend.

- The fireproof chamber is made of UL94 V-0 class materials.