- Stock: Out of stock

- Product code: GEN-08155291

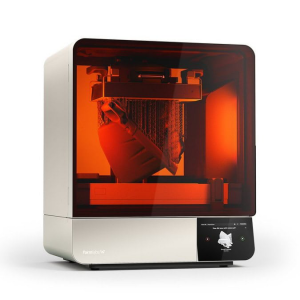

ProJet MJP 2500W Plus 3D Printer from 3D Systems

Introducing the ProJet MJP 2500W Plus — a high-performance 3D printer for printing high-quality wax patterns for metal jewelry casting.

High-yield production of master patterns for jewelry from pure wax for investment casting.

The ProJet MJP 2500W Plus is a wax 3D printer that burns out 100% ash-free, just like standard wax in traditional jewelry casting. The production of such jewelry patterns adapts to your workflow, printing from a few small batches per day to larger assemblies with high throughput.

This affordable printer combines high speed with a large build volume of 294×211×144 mm for high productivity of precise and fine models for jewelry casting using a 3D printer.

Casting Quality

The ProJet MJP 2500W Plus prints using 100% VisiJet wax materials, creating durable, high-quality jewelry models that ensure reliable casting with excellent results in traditional investment casting processes and equipment.

VisiJet wax materials melt the same way as standard casting waxes, with zero ash content, ensuring defect-free castings. It's durable for handling and casting fine details, and high-contrast colors make it easy to visualize minute features.

High Productivity

With the ProJet MJP 2500W Plus printer, you'll have high-volume production of pure wax casting patterns or fast single-pass printing with high print speeds to boost foundry efficiency — from short runs to high throughput. Thanks to the large build volume and 24/7 operation, the high productivity of this low-cost printer means rapid amortization and a high return on investment.

Optimize your workflow from 3D model to pattern with advanced 3D Sprint software capabilities, MJP's fast and versatile print speed, and batch support removal to obtain high-quality, cast-ready jewelry patterns.

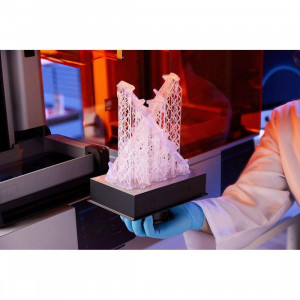

High-Detail Wax Patterns

Seamlessly print CAD jewelry patterns with excellent feature translation, featuring thin, even sharp edges and extremely crisp detail. Superior resolution and dissolvable and melt-away supports provide excellent surface quality, which reduces labor costs for finishing and polishing expensive precious metals. These high-precision, thin wax models are printed directly, without the time, waste, and geometric constraints associated with tooling.

Applications

- Custom and serial production of metal jewelry.

- Manufacturing custom metal jewelry.

Advantages

- Rapidly delivers many patterns, ensuring the seamlessness of your metal casting workflow.

- High-precision patterns you can rely on.

- Exceptionally sharp edges, crisp details, and smooth surfaces.

- Great geometric freedom due to efficient dissolvable support removal.

- Highly efficient, durable casting wax.

- Low Total Cost of Ownership (TCO).

Technical Specifications

- MultiJet Printing (MJP) Technology.

- Maximum Build Volume (W×D×H): 294×211×144 mm.

- 100% wax cast models for use in standard processes.

- Optimized workflow from file to print with 3D Sprint software capabilities.

- Cloud connectivity for predictive and rapid service with 3D Connect™.

- Fast and easy post-processing with dissolvable support.

Print Mode Parameters

| XHD Print Mode | ZHD Print Mode | |

|---|---|---|

| Resolution (dots/inch) | 1200*1200*1600 | 1200*1200*3200 |

| Layer Thickness (µm) | 16 | 8 |

| Single-pass build | ||

| Throughput (cm3/h) | 147 | 75 |

| 1 inch / 2.54 cm Height Accumulation (hours) | 4 | 8 |

| Dual-pass build | ||

| Throughput (cm3/h) | 141 | 72 |

| 1 inch / 2.54 cm Height Accumulation (hours) | 8 | 16 |

| Triple-pass build | ||

| Throughput (cm3/h) | 134 | 69 |

| 1 inch / 2.54 cm Height Accumulation (hours) | 12 | 24 |