- Stock: In Stock

- Product code: 00-08800490

- Shipping Weight: 0.50kg

Available Options

Ultrafuse® Support Layer – support material for metal filaments

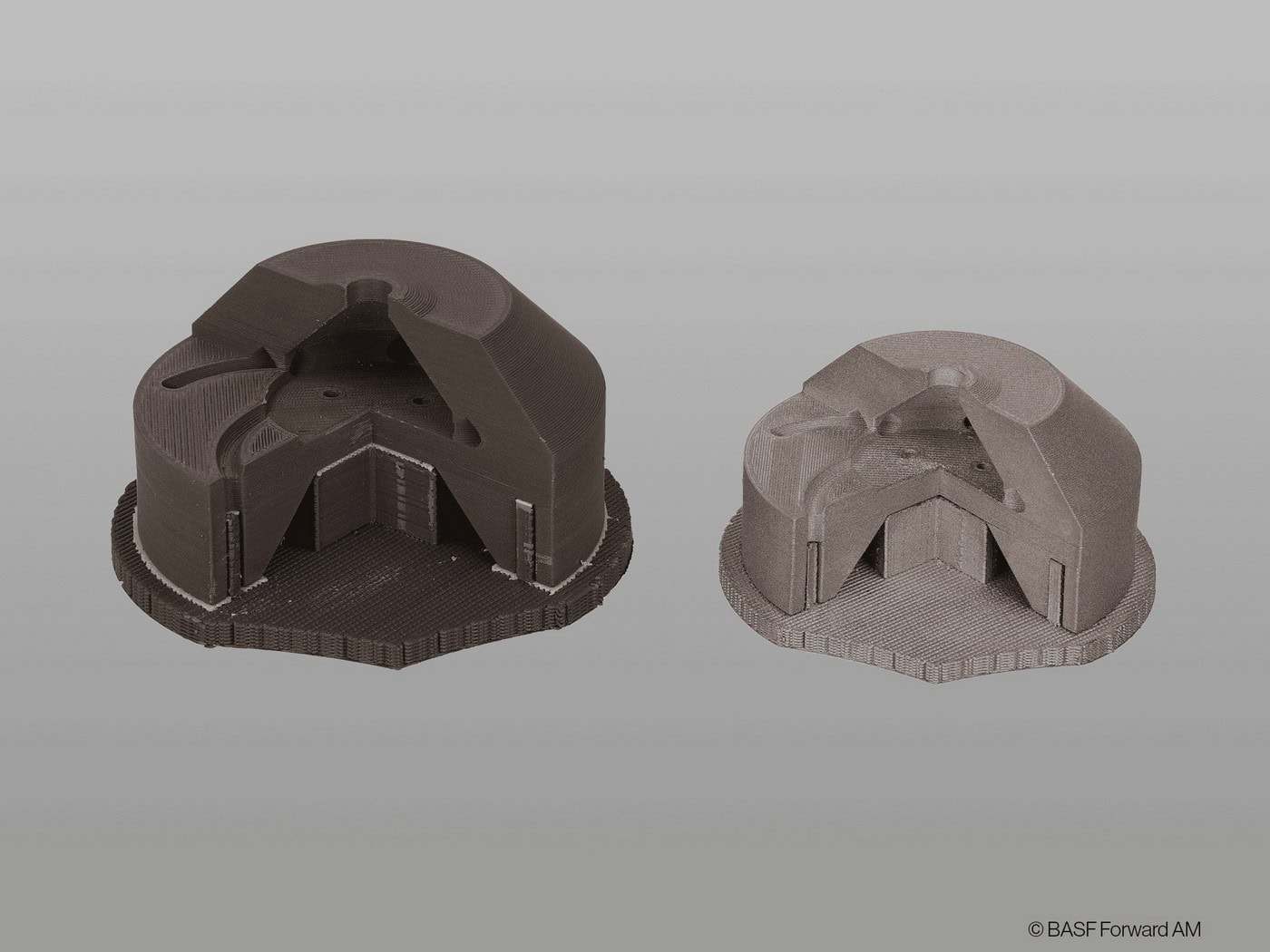

Ultrafuse Support Layer Filament for Metal 3D Printing in combination with Ultrafuse® metal filaments. The advantage of the material is that it forms a barrier between the support structures and the object during sintering, making it easier to separate the support from the metal part.

Ultrafuse® Support Layer is not designed for printing individual parts and should be printed as a layer attached to the support structures in dual extrusion prints.

Key Benefits

- Can be printed on any FFF metal printer*.

- Allows printing of a wider range of designs and complex geometries.

- Excellent surface quality of the support areas of the part.

- Minimizes distortion of the printed part during binder removal and sintering.

- Simplified workflow for preparing parts for sintering.

* It is recommended to use a coated hardened nozzle or a ruby nozzle for printing.

Easy 3D printing with metal from BASF Ultrafuse

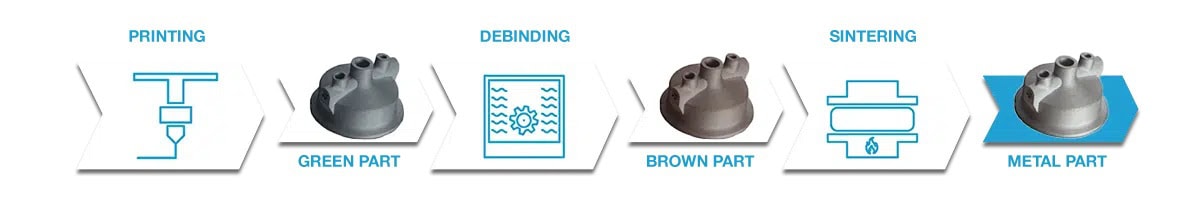

BASF Ultrafuse metal filaments are specially designed for easy use on standard FFF/FDM 3D printers – the most common type of printing equipment. Ultrafuse® 316L and 17-4 PH materials offer more design options at a reduced cost of ownership, making the process of printing metal parts easier, faster and more cost-effective. The additional Ultrafuse® Support Layer material enables printing with easily removable supports and supports the necessary post-processing processes. This significantly expands the range of use and application of the material. The final post-processing steps – debinding and sintering – are carried out via specialized online portals Debinding & Sintering or on equipment in-house.

Printing

Printing with BASF Ultrafuse® metal filament is very similar to FFF printing with plastic, but there are a few important details that need to be taken into account to ensure that a fully metal part can be produced.

Washing and Sintering

Once the part has been printed, the next step is washing and sintering – processes that differentiate metal printing from typical FFF 3D printing. Only after these are completed do we have a fully metal part.

Ultrafuse® Support Layer: applications

- Tooling

- Clamping devices and fixtures

- Series production of solid metal parts

- Functional parts and prototypes

Material details

- Technical Data Sheet (EN)

- User Guide for Support Layer

- User Guide for Metal Printing

- Removal of Bonds Modeling Guidelines

- Workflow Guidelines

- Safety Data Sheet (EN)

- Print Profiles for Raise3D

Specification

| Printing technology | FFF |

| Plastic Diameter (mm) | 1,75/2,85 |

| Diameter tolerance (mm) | ±0.050 |

| Roundness (mm) | ±0.050 |

| Coil outer diameter (mm) | 200 |

| Inner diameter of coil (mm) | 50.5 |

| Width (mm) | 55 |

| Printing Temperature (°C) | 240 – 260 °C |

| Build chamber temperature | Passively heated, closed chamber |

| Nozzle diameter (mm) | ≥ 0.4 |

| Print speed (mm/s) | 15 – 20 |

| Compatibility with materials | BASF Ultrafuse 316L, BASF Ultrafuse 17-4PH |

| Compatibility with printers | Verified printer brands: UltiMaker, MakerBot, Raise3D, BCN3D, Zortrax |

| Country of Origin | Germany |

| Weight of Plastic (kg) | 0,3 |