- Stock: In Stock

- Product code: 00-08800486

- Shipping Weight: 1.30kg

Available Options

Ultrafuse® 316L Metal Filament

BASF Forward AM Ultrafuse 316L stainless steel composite metal filament for FFF 3D printers.

Ultrafuse® 316L is an innovative 316L stainless steel part material designed to seamlessly run on conventional Fused Filament Fabrication (FFF) 3D printers, offering a cost-effective and simple solution for creating high-quality metal parts. This advanced filament combines design freedom with a lower total cost of ownership, making metal 3D printing faster, easier, and more affordable.

Ultrafuse® 316L is designed to support a wide range of applications such as tooling, fixtures, fasteners, small-scale production, functional parts, prototypes, and even jewelry. The filament is a cutting-edge metal-polymer composite containing approximately 90% highly purified metal particles combined with thermoplastic binders for ease of use.

With its non-slip surface, Ultrafuse® 316L is compatible with most Bowden or direct drive extruders and easily navigates complex filament paths. Its high flexibility eliminates the need for additional drying, and the composite avoids the safety risks associated with handling fine metal powders, making printing affordable, simple and safe.

Material properties:

Excellent corrosion resistance

Temperature stability

Austenitic

Non-magnetic

Key benefits:

- Easy and affordable metal 3D printing

- Quick material exchange and easy use

- For all open source FFF printers

- Production of parts from 316L stainless steel.

- Uniform particle distribution improves mechanical properties.

- High filament flexibility allows successful printing on any FFF printer.

- Compatible with both Bowden and direct drive extruders.

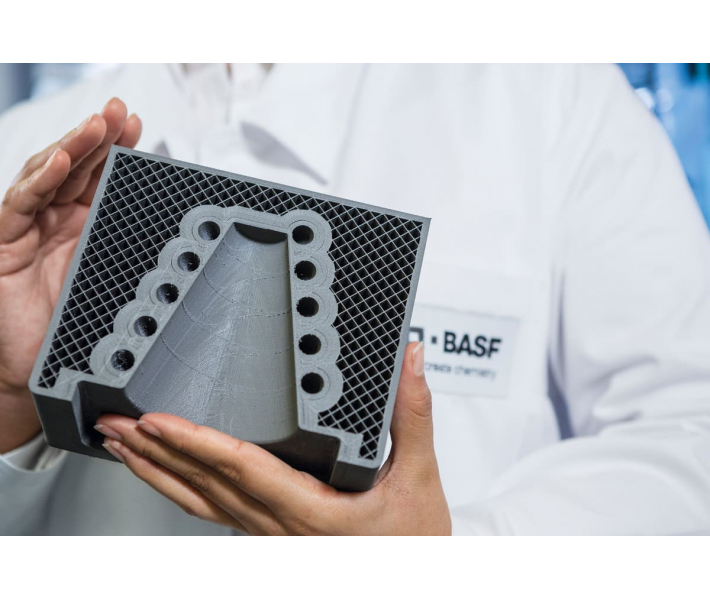

Lightweight Metal 3D Printing with BASF Ultrafuse

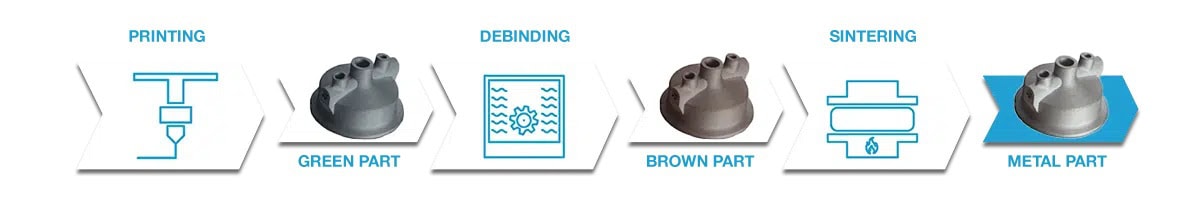

The final properties of the printed parts, including stiffness and strength, are achieved through a catalytic debonding and sintering process. This industry-standard process, originally developed and introduced by BASF, delivers excellent results while meeting metal injection molding (MIM) standards.

BASF Ultrafuse metal filaments are specifically designed for easy use on standard FFF/FDM 3D printers – the most common type of printing equipment. Ultrafuse® 316L and 17-4 PH materials provide greater design flexibility at a reduced cost of ownership, making the process of printing metal parts simpler, faster and more cost-effective.

The optional Ultrafuse® Support Layer material enables printing with easily removable supports and supports the necessary post-processing processes. This significantly expands the range of uses and applications of the material. The final post-processing steps – debinding and sintering – are carried out via dedicated online portals Debinding & Sintering or on equipment in-house.

Printing

Printing with BASF Ultrafuse® metal filament is very similar to FFF printing from plastic, but there are a few important details that need to be taken into account to ensure that a fully metal part can be produced.

Rinse and Sinter

Once the part has been printed, the next step is rinse and sinter – processes that differentiate metal printing from typical FFF 3D printing. Only after these are completed do we obtain a fully metal part.

BASF Forward AM Ultrafuse® 316L Metal Filament: applications

Tools

Clamps and Fixtures

Functional Prototypes

Small-Scale Production

Material details:

- Product card

- Technical data sheet (EN)

- User instructions

- Removal of union modeling recommendations

- Process instructions

- Safety data sheet (EN)

- Printing profiles for Raise3D

Specification:

| Printing technology | FFF |

| Plastic diameter (mm) | 1,75 / 2,85 |

| Diameter tolerance (mm) | ±0.050 |

| Circumference (mm) | ±0.050 |

| Coil outer diameter (mm) | 200 |

| Inner diameter of coil (mm) | 50.5 |

| Width (mm) | 55 |

| Printing Temperature (°C) | 230 – 250 °C |

| Table temperature | 90 – 100 °C |

| Table material | Glass + approved adhesives* / polyimide tape (*Magigoo® recommended) |

| Nozzle diameter (mm) | ≥ 0.4 |

| Print speed (mm/s) | 15 – 50 |

| Compatibility with supporting materials | Ultrafuse® Support Layer |

| Compatibility with printers | Tested printer brands: UltiMaker, MakerBot, Raise3D, BCN3D, Zortrax |

| Density of sintered parts | 7850 кг/м3, ISO 3369 |

| Country of origin | Germany |

| Weight of plastic (kg) | 1.0 / 3.0 |