- Stock: In Stock

- Product code: 00-08800482

- Shipping Weight: 1.30kg

Available Options

Metal 3D Printing with Ultrafuse® 17-4 PH

Metal 3D Printing with Ultrafuse® 17-4 PH metal filament is a plastic for 3D printing of stainless steel metal

components for applications requiring high hardness and mechanical strength.

Ultrafuse® 17-4 PH is a

material designed for the production of 17-4 stainless steel metal components on standard Fused Filament

Fabrication (FFF) printers.

Ultrafuse® 17-4 PH offers an efficient way to produce metal parts with high mechanical strength. The material is compatible with most FFF 3D printers, giving you a high degree of flexibility and freedom.

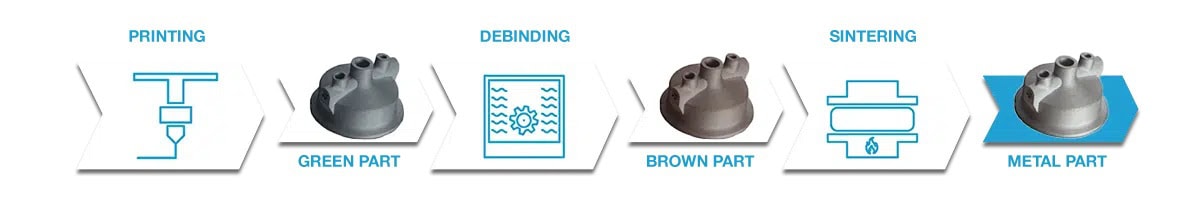

This stainless steel can be fully heat-treated to achieve high levels of strength and rigidity. Therefore, it is ideal for the petrochemical, aerospace and automotive industries. Parts printed with Ultrafuse® 17-4 PH metal-polymer composite filament achieve their final properties through a catalytic debinding and oven sintering process known from traditional metal injection molding.

Material Properties

Heat Treated Stainless Steel Parts

Increased Strength and Rigidity through Dispersion Strengthening

Martensitic

Magnetic

Key Benefits

- Lightweight and affordable metal 3D printing

- High mechanical strength and rigidity

- Good corrosion resistance

- Fully hardened for high strength

- Wide range of post-processing options for green parts

Lightweight metal 3D printing with BASF Ultrafuse

BASF Ultrafuse metal filaments are specially designed for easy use on standard FFF/FDM 3D printers – the most common type of printing equipment. Ultrafuse® 316L and 17-4 PH materials offer greater design flexibility at a reduced cost of ownership, making the process of printing metal parts simpler, faster and more cost-effective.

The optional Ultrafuse® Support Layer material enables printing with easily removable supports and supports the necessary post-processing processes. This significantly expands the range of possible uses and applications of the material. The final post-processing steps – debinding and sintering – are carried out via specialized online Debinding & Sintering portals or on equipment in-house.

Printing

Printing with BASF Ultrafuse® metal filament is very similar to FFF printing with plastic, but there are a few important details that need to be taken into account to ensure that a fully metal part can be produced.

Washing and Sintering

Once the part has been printed, the next step is washing and sintering – processes that differentiate metal printing from typical FFF 3D printing. Only after these are completed do we have a fully metal part.

BASF Forward AM Ultrafuse® 17-4 PH Metal Filament: applications

Tools

Clamps and Fixtures

Functional Prototypes

Material details

- Product card

- Technical data sheet (EN)

- User instructions

- Process instructions

- Safety data sheet (EN)

- Printing profiles for Raise3D

Specifications

| Printing technology | FFF |

| Plastic diameter (mm) | 1,75 / 2,85 |

| Diameter tolerance (mm) | ±0.050 |

| Circumference (mm) | ±0.050 |

| Coil outer diameter (mm) | 200 |

| Inner diameter of coil (mm) | 50.5 |

| Width (mm) | 55 |

| Printing Temperature (°C) | 230 – 250 °C |

| Table temperature | 90 – 100 °C |

| Table material | Glass + approved adhesives* / polyimide tape (*Magigoo® recommended) |

| Nozzle diameter (mm) | ≥ 0.4 |

| Print speed (mm/s) | 15 – 50 |

| Compatibility with supporting materials | Ultrafuse® Support Layer |

| Compatibility with printers | Tested printer brands: UltiMaker, MakerBot, Raise3D, BCN3D, Zortrax |

| Density of sintered parts | 7850 кг/м3, ISO 3369 |

| Country of origin | Germany |

| Weight of plastic (kg) | 1.0 / 3.0 |