- Stock: Out of stock

- Product code: 00-08800348

- Shipping Weight: 1.30kg

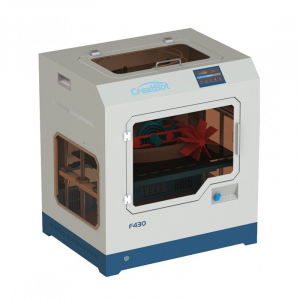

3D PEEK plastic 3DDevice

PEEK plastic occupies a place of honor among advanced polymers for additive manufacturing. It is a strong, refractory material with a high deformation and melting temperature. PEEK 3DDevice plastic is a familiar material in industry, and with the development of 3D technologies, it has gained new prospects. The only obstacle to the use of PEEK with desktop 3D printers is its melting point. The printer extruder must be heated to at least 350˚C.

How can PEEK plastic be used? It is a very strong and reliable material, ideal for engineering applications. It is often used in the aerospace, medical, and automotive industries, as well as in the manufacture of electrical appliances, etc. In consumer 3D printing, it will be useful wherever increased product strength is required and where the properties of other 3D plastics are insufficient. This page features PEEK plastic (70% PEEK, 30% carbon fiber), reinforced with carbon, which significantly increases its strength and improves its characteristics.

Material properties

- Chemical resistance;

- Very high maximum permissible operating temperature;

- High mechanical strength and rigidity;

- Wear resistance;

- High creep resistance;

- Resistance to gamma and X-ray radiation;

- Low flammability and smoke emission during combustion.

Technical specifications

| Parameter | Standard | Value |

| Color | Black | |

| Thread diameter | 1,75 mm | |

| Density | ISO 1183 | 1,4±0,01 g/cm3 |

| Solubility in water (24 hours at 25°C) | ISO 62 | 0,06% |

| Shrinkage percentage | 3 mm, 170˚С, flow direction | 0,1% |

| Perpendicular to the flow direction | 0,5% | |

| Melting point | DSC | 343 ˚С |

| Deformation temperature | ASTM D648 | 315 ˚С |

| Continuous use temperature | UL 74685 | 260 ˚С |

| Coefficient of thermal expansion | ASTM D696 | 1,5*10-5 ℃ |

| Elongation (at 23 ° С) | ISO527-2/1B/50 | 200 MPa |

| Elongation (at 23 ° С) | ISO527-2/1B/50 | 1,8% |

| Flexural strength (at 23 ° С) | ISO 178 | 298 MPa |

| Compressive strength (at 23˚С) | ASTM D695 | 240 MPa |

| Izod impact strength (unnotched) | ISO 180/U | 46 |

| Rockwell Hardness | ASTM D785 | 107 |

| Flammability level | UL 94 | 1,5 V-0 @mm |

| Dielectric strength | IEC 248 | |

| Dielectric constant | IEC 250 | |

| Surface resistance | 3*106 Om | |

| Friction coefficient | 0,28 μ | |

| Coil weight | 1 kg |