Прес-форми на 3D принтері Formlabs

Прес-форма – це складної геометрії пристрій з металу для лиття пластмасових виробів. Ідея створення прес-форми на 3D принтері давно лежала “на поверхні”. Пошуки більш дешевих і більш швидких способів виробництва звертають погляди в бік 3Д друку. Нові технології швидко розвиваються. Ще вчора 3Д друк створював досить грубі макети і прототипи, вже сьогодні адитивні технології готові запропонувати досить точні та функціонально-робочі деталі і пристосування.

Американська компанія Formlabs створила повністю автоматизований життєвий цикл промислового фотополімерного 3D друку. У Formlabs зробили упор на 3Д друк виключно своїми фотополімерами (які також називають смолами). Таким чином, відповідаючи на постійно зростаючий попит, у Formlabs розробляють нові формули, які знаходять застосування в тому числі в дрібносерійному виробництві. Ряд інженерних смол Formlabs легко справляються з жорсткими умовами процесу лиття під тиском. 3D-друковані прес-форми з жорстких і міцних смол Formlabs відмінно підходять для дрібносерійного виробництва без поломок і витоків.

У порівнянні з традиційною обробкою на металевих прес-формах, доступність 3D-друкованих форм, надрукованих на 3D-принтерах, призводить до більш швидкої окупності інвестицій і допомагає клієнтам швидко виводити продукти на ринок.

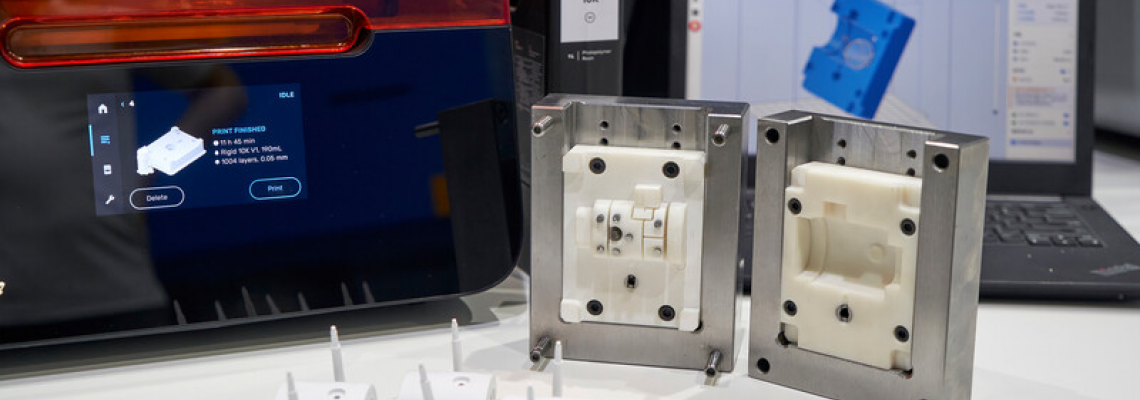

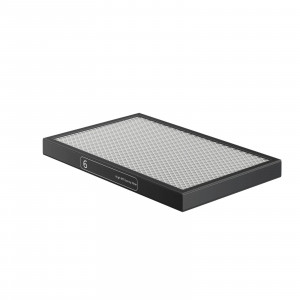

Лиття під тиском у прес-форми, надруковані на 3D-принтері

Такі форми використовуються для лиття під тиском. Для успішної роботи у цьому технологічному процесі, форми мають витримувати: тиск затиску, тиск впорскування і температуру уприскування. Крім цього, витримувати будь-які охолоджуючі рідини або мастила для форм, які можуть використовуватися. Стабільність форми до дії цих факторів гарантує, що її можна буде довго і багаторазово використовувати. І при цьому, вона повинна стабільно виробляти деталі, ідентичні оригінальній конструкції. Це важливо!

Форми, роздруковані на 3D-принтерах Formlabs, були протестовані на настільних і промислових машинах для лиття під тиском в широкому діапазоні умов. Ці прес-форми невеликого обсягу здатні витримувати від сотень до тисяч впорскувань в залежності від декількох факторів:

- конструкція деталі;

- матеріали прес-форми і лиття під тиском;

- параметри формування;

- охолоджуючі рідини і мастила для вилучення з форми.

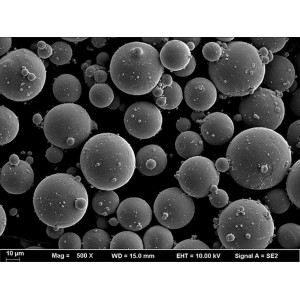

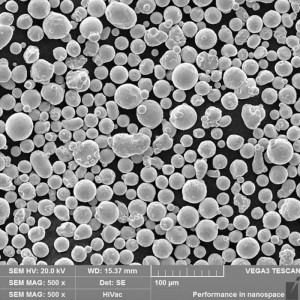

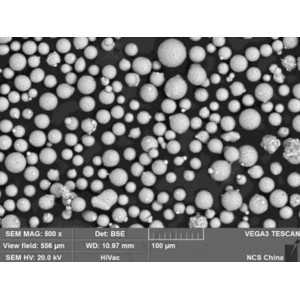

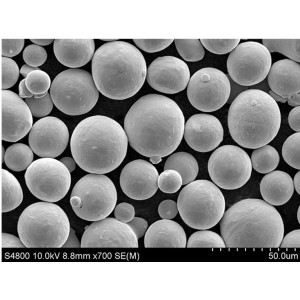

Фотополімери для 3D друку прес-форм

Formlabs пропонує ряд матеріалів, які можуть замінити алюмінієві форми для виробництва невеликих серій продукції.

- Смола Rigid 10K Resin поєднує в собі такі корисні якості як міцність, жорсткість і термічний опір. Саме тому, вона є ідеальним матеріалом для ливарних форм. Підвищена міцність гарантує, що прес-форма з Rigid 10K зможе витримувати тиск затиску і впорскування без руйнування. А висока жорсткість дозволяє прес-формі зберігати свою форму під цим тиском і виготовляти точні деталі.

- High Temp Resin – це більш дешевий альтернативний матеріал, що витримує температуру до 238 °C. Його використання можна допустити, якщо тиск затиску і уприскування не надто високий. У тих випадках, коли Rigid 10K Resin не може відповідати необхідним температурам уприскування.

- Якщо точність розмірів формованих деталей менш важлива, обирайте Grey Pro Resin. Вона працює за більш низького тиску і температури. І, в той же час, більш гнучка. Форма з цього матеріалу потенційно більш довговічна, тому що це більш гнучкий матеріал, який гнеться перед тим, як зламатися. У той же час, це потенційно знижує точність з часом у міру використання форми.

Скільки циклів витримує прес-форма, надрукована на 3D принтері?

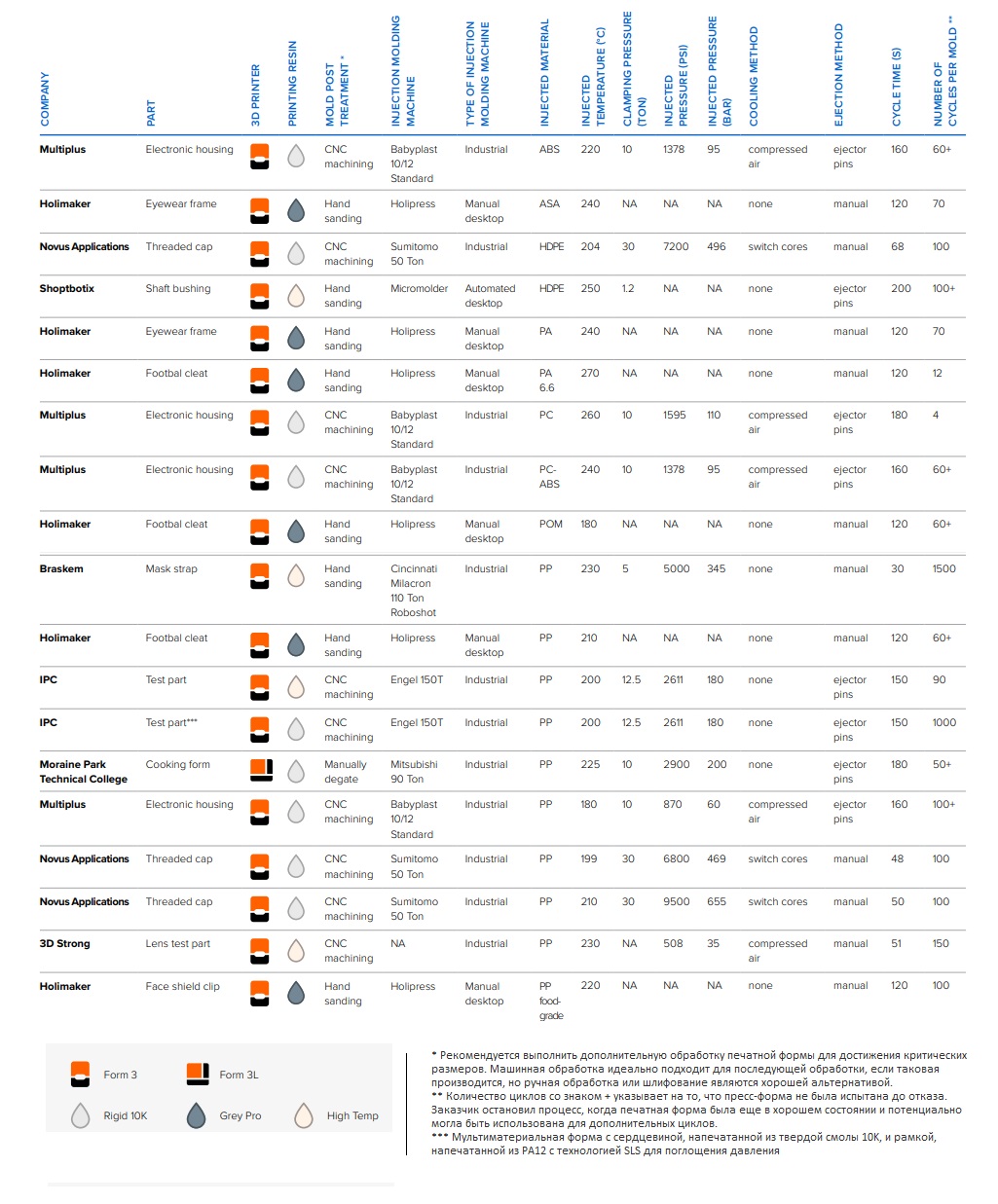

Нижче ви можете побачити, що форми, роздруковані на 3Д принтері, витримують достатню кількість циклів для виробництва дрібних партій товарів. Це досить надихаюча інформація, адже дрібносерійне виробництво завжди було витратною і клопіткою справою. Традиційні прес-форми з металу коштують дорого і залежать від тривалих поставок. І це значно позначається на собівартості дрібнопартійних виробів. Застосування ж 3D принтера Formlabs для друку прес-форм, істотно знижує тимчасові і матеріальні витрати!

Умови процесу лиття під тиском з використанням форм, надрукованих на 3D-принтері. Кількість циклів використання прес-форм

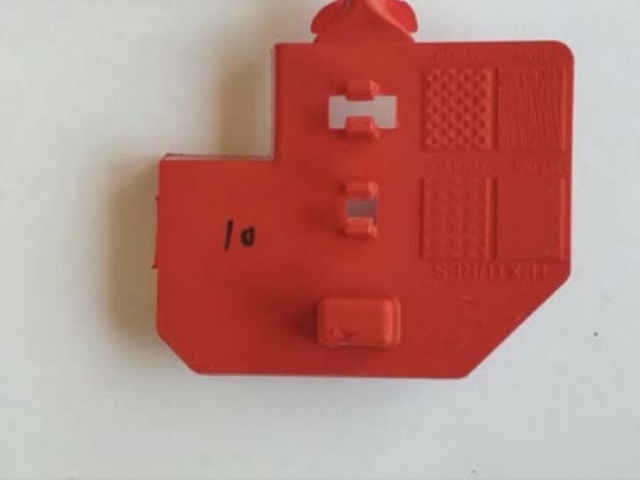

Зразки виробів, відлитих у 3Д-друковані прес-форми

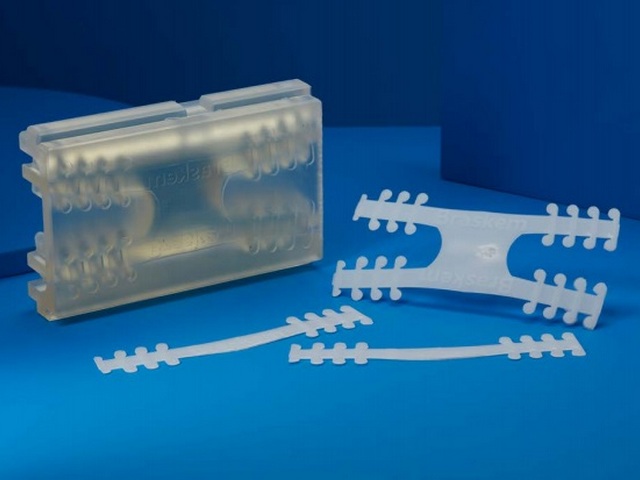

Кришка з різьбленням від Novus Applications. Матеріал прес-форми: смола Formlabs Rigid 10K

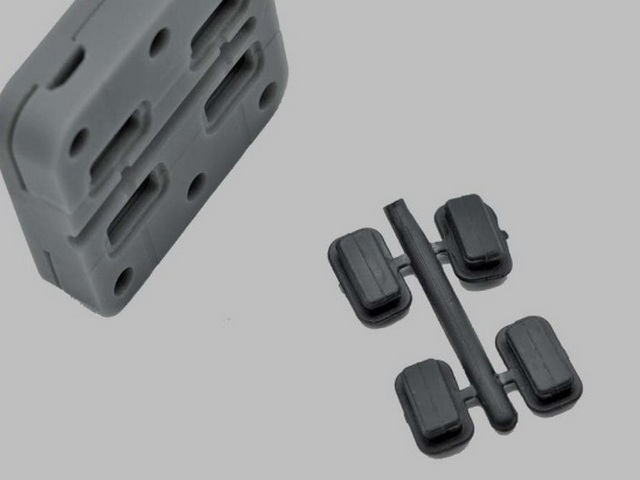

Тримач для медичної маски від Braskem. Матеріал прес-форми: смола Formlabs High Temp

Футбольний шип від Holimaker. Матеріал прес-форми: смола Formlabs Grey Pro

Корпус електронного пристрою від Multiplus

Втулка вала от Shopbotix

Затискач для захисту обличчя від Holimaker

Оправа окулярів від Holimaker

Тестова деталь від IPC

Залишити коментар