- 1. 3D Printing Cocooner — a New Development!

- 2. 3D Printing Cocooner — a New Development!

- 3. 3D Printing Cocooner — a New Development!

- 4. 3D Printing Cocooner — a New Development!

- 5. 3D Printing Cocooner — a New Development!

- 6. 3D Printing Cocooner — a New Development!

- 7. 3D Printing Cocooner — a New Development!

3D printing Cocooner — a new development by the German company Festo!

Although 3D printing is an evolving technology, with many possibilities yet to be discovered, it already provides a wide field of opportunities for developers and designers. Many of them strive to go beyond the usual additive manufacturing techniques, creating truly unimaginable structures. Fortunately, thanks to 3D modeling, any imagination can now be realized, and designers can freely unleash their creative potential.

3D Printing Cocooner — a New Development!

One practice gradually gaining popularity among individuals and organizations alike is the combination of innovative technologies and biological systems. Among the organizations practicing this approach is the German company Festo, which has previously amazed us with a series of stunning robotic biomimetic systems created using a 3D printer. These systems include remarkable 3D-printed insects, birds, butterflies, and animals capable of performing complex tasks and connected wirelessly.

3D Printing Cocooner — a New Development!

The new development represents a unique 3D printing technique that allows creating complex fiberglass structures in mid-air. The polymer feed device itself is unusual and is an original modification of a 3D printer. Interestingly, the mechanism’s design was inspired by caterpillars.

3D Printing Cocooner — a New Development!

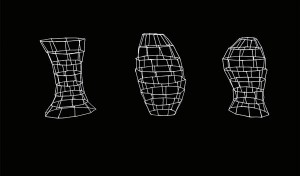

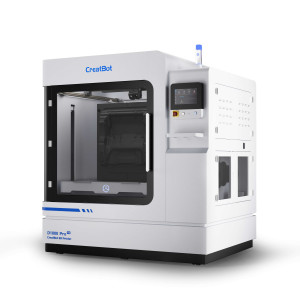

3D Cocooner is currently Festo’s most significant development in the world of 3D printing. Its unique design, consisting of a vertically positioned stand and a robotic extruder, allows the device to quickly and precisely reproduce complex, freely-standing lattice 3D structures that do not require additional support. This is because, unlike traditional manufacturing methods, the fiberglass in 3D Cocooner solidifies directly in the air thanks to the built-in UV curing system.

3D Printing Cocooner — a New Development!

The control system of the mechanism receives parametric data from the 3D model through connected software. This software displays not only the product’s design information but also the processing system itself, calculating the optimal construction path in real time. Polymer fibers can be redirected and cut for reconnection with other parts of the structure, enabling even more complex architectures. Additionally, the company claims that finished objects exhibit excellent tensile and bending strength.

3D Printing Cocooner — a New Development!

Currently, 3D Cocooner has a working space of 450x300x600 mm and a printing speed of 10 mm/s. Festo believes the platform can be used to create complex 3D shapes that are impossible to produce with traditional 3D printing methods. Additionally, the lightweight but strong lattice structures can be covered with film or fabric to form solid enclosed objects.

3D Printing Cocooner — a New Development!

Festo is not the only organization developing such constructions. News about a 3D-printed chameleon capable of changing color and a 3D-printed scorpion with an active stinger are widely known. However, 3D Cocooner is one of the first inventions using biomimetic technologies. It not only employs 3D printing principles but also visually demonstrates the construction scheme of 3D objects. 3D Cocooner will debut at Hannover Messe in Germany from April 25 to 29. But you can already see it in action by watching the video linked below:

3D Printing Cocooner — a New Development!

https://www.youtube.com/watch?time_continue=96&v=9QCOTisgIHQ

Leave a Comment