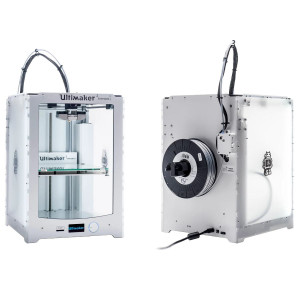

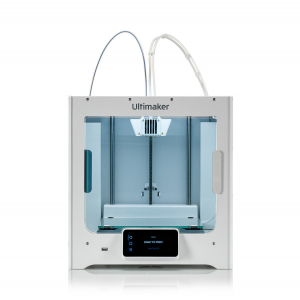

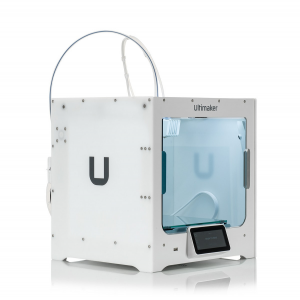

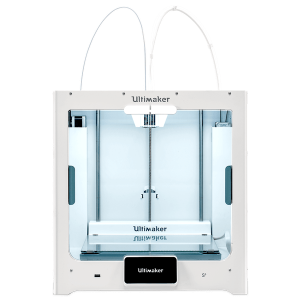

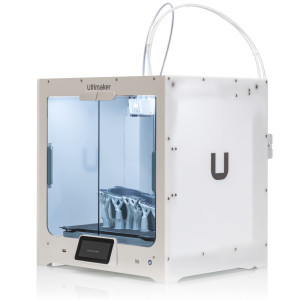

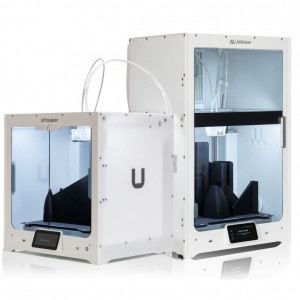

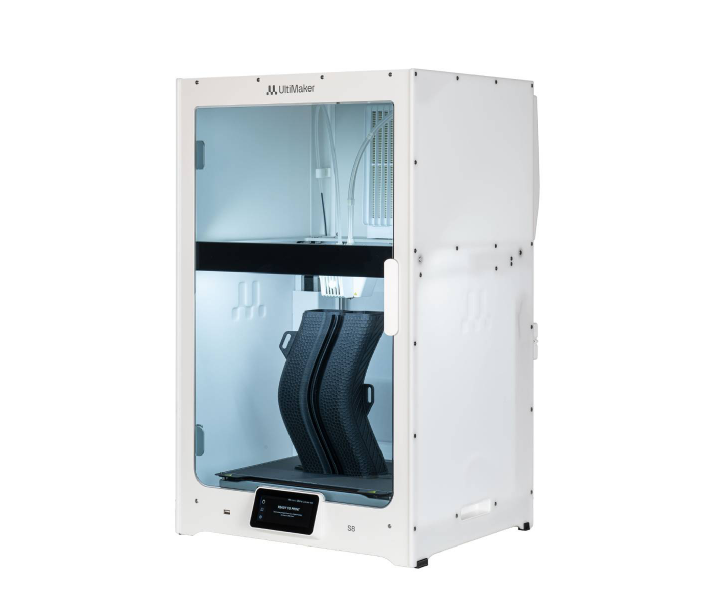

3D printer UltiMaker S8

Price Incl. VAT

- Stock: In Stock

- Product code: 00-00012981

- Shipping Weight: 36.00kg

Based on 0 reviews.

-

Write a comment

₴811 024.00

Ex Tax: ₴811 024.00

Quantity:

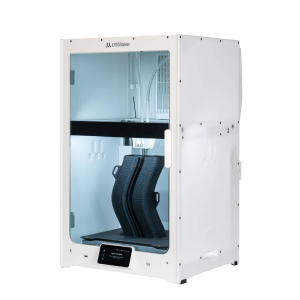

UltiMaker S8 is an improved 3D printer, next-generation

UltiMaker S8 is an improved 3D printer designed for professional use. The printer differs from the 7 model in terms of print quality, reliability and speed. With its innovative technology and advanced design, the UltiMaker S8 takes 3D printing to the next level. Wherever you want to use the S8, it’s a reliable tool for a variety of applications. Its versatility and reliability make it suitable for a wide range of applications.

Applications of the UltiMaker 3D printer

- Industrial production.

- Prototyping.

- Tool and die manufacturing.

- Low-volume production.

- Spare parts manufacturing.

- Engineering and design.

- Architectural modelling.

- Product design.

- Aerospace industry.

- Automotive industry.

- Medicine.

- Medical modelling.

- Manufacturing of prostheses and orthoses.

- Dentistry.

- Education and research

- 3D printing training.

- Scientific research.

Design and

- Art.

- Manufacturing of design products.

- Art Sculpture Fabrication.

Other areas

- Robotics: Manufacturing components for robots.

- Jewelry: Making prototypes for jewelry.

- Consumer Product Manufacturing: Prototyping and finishing products for the consumer market.

UltiMaker S8 Technical Parameters

- Printing Technology: Fused Deposition Modeling (FDM)

- 2 extruders (can print with 2 materials)

- Soluble support printing material can be used

- Filament diameter: 2.85 mm

- Dimensional accuracy: ± 0.15 mm ± 0.15% of nominal length of element

- XY speed, acceleration, jerk: Up to 500 mm/s, up to 50,000 mm/s², up to 100,000,000 mm/s³

- Extrusion Capacity: Up to 35 mm³/sec.

- Nozzle temperature: Up to 340 °C

- Heated stage temperature: Up to 120 °C

- Build area: 330*240*300 mm

- Printer weight: 30 kg

UltiMaker S8 Features

- Fastest desktop 3D printer with two materials.

- Open platform for materials.

- UltiMaker Cheetah is an innovative motion planner.

- Powered by the UltiMaker ecosystem.

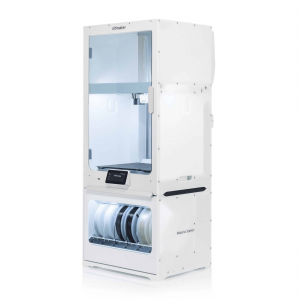

- Improved material feeding system.

- High-precision printing cores.

- Compatible with a variety of plastics (Tough PLA, PLA, PETG, ABS, CPE, CPE+, Nylon, TPU 95A, PP).

Advantages of UltiMaker S8

- High performance

- UltiMaker Cheetah motion planner.

- High performance upgraded print cores.

- New filament feed system.

- Built-in accelerometer.

- Improved software.

Dual extrusion

- Print with multiple materials with different properties.

- Multicolor printing.

- Minimized waste.

- Increased reliability.

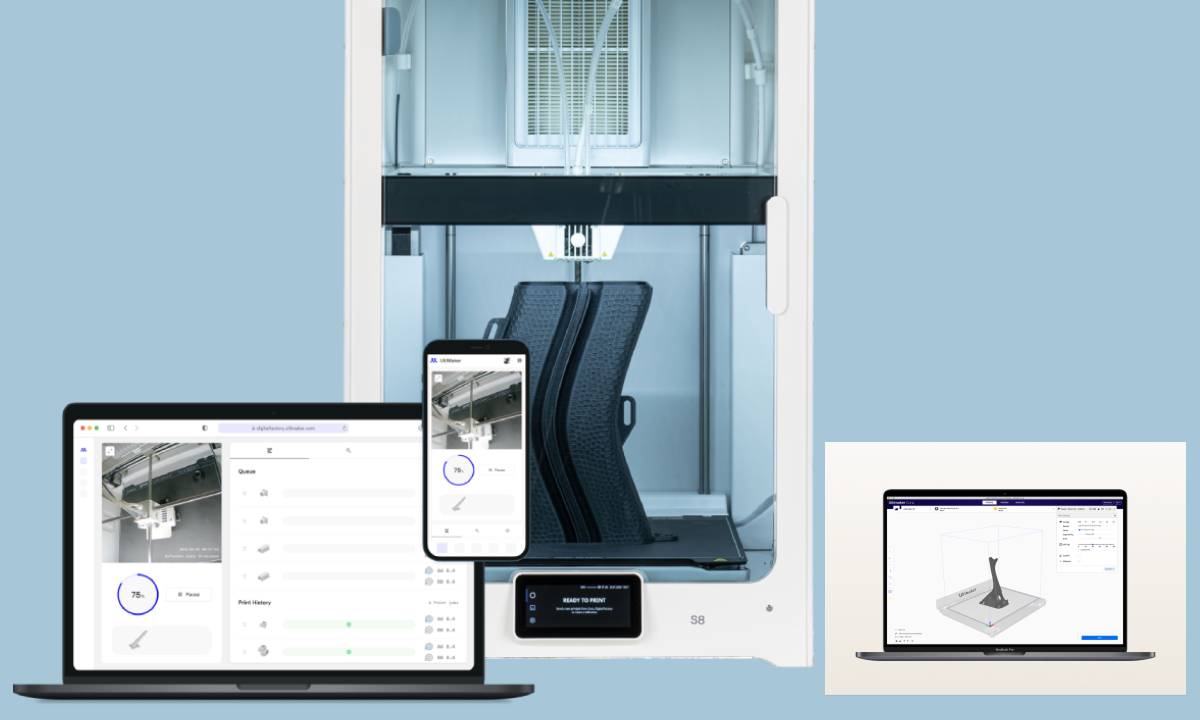

Digital Factory

- The convenience of slicing and printing in one solution.

- Built-in hardware and software security features.

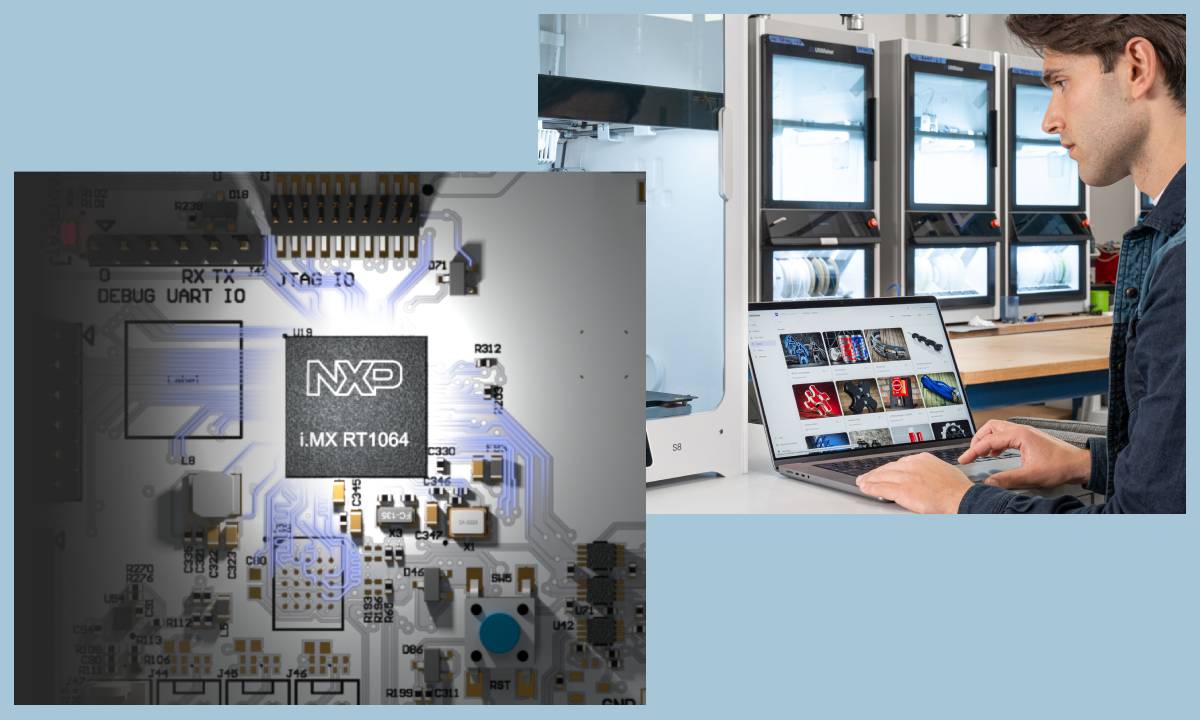

High level of security

- Safe reliable hardware.

- Advanced firmware.

- UltiMaker S8 3D printer designed in Europe.

Improved Material Handling System

- Reinforced feed module for reliable material control.

- More accurate adhesion.

Dual extrusion design and new printing cores

- High-flow AA and CC+ print cores with a unique four-chamber design.

- Increased throughput by 2.5 times.

- Optimized print head pressure.

- Two extruders with high flow rate support.

Efficient air filtration

- Integrated EPA filter that removes up to 95% of ultrafine particles.

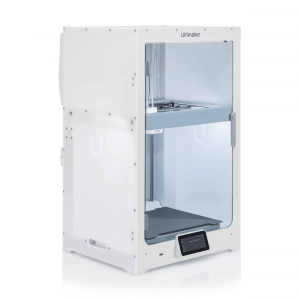

- Fully enclosed print chamber for stable conditions.

Flexible build plate

- PEI coating for easy removal of parts.

- 25 magnets and 4 pins for perfect alignment.

Integration with Cura

- Intent profiles for easy parameter customization.

- Remote printing.

- Advanced features for enhanced print quality and convenience.

UltiMaker S8: the ultimate solution for professional-grade 3D printing

The UltiMaker S8 combines innovative technology, safety and performance. It’s the 3D printer of choice for design and manufacturing professionals.

Technical specifications of the UltiMaker S8 3D printer

| Printing Technology | FDM |

| Build Field (mm) | 330*240*300 |

| Ø Of Plastic (mm) | 2,85 |

| Maximum Nozzle Temperature (°C) | Up to 340 °C |

| Number Of Extruders | 2 |

| Chamber Type | Closed |

| Heating The Chamber | No |

| Filament Drying | Optional |

| Autocalibration | Yes |

| Feeder Type | Bowden |

| Layer Height (micron) | 0.25 mm nozzle: 150 – 60 μm / 0.4 mm nozzle: 200 – 20 μm / 0.6 mm nozzle: 300 – 20 μm / 0.8 mm nozzle: 600 – 20 μm |

| Nozzle Diameter (mm) | 0,25 / 0,4 / 0,6 / 0,8 |

| Nozzle Warm-Up Time (min) | 2 |

| Positioning Accuracy (µm) | XY: 6.9; Z: 2.5 |

| Platform Heating | Yes |

| Maximum Platform Temperature (°C) | 140 |

| Platform Warm-Up Time (min) | Up to 5 (from 20 to 60 °C) |

| Platform Material | PEI-coated flexible steel build plate |

| Supported Materials | Tough PLA, PLA, PETG, ABS, CPE, CPE+, Nylon, TPU 95A, PP. |

| Material Recognition | Automatic – NFC scanner |

| Running Noise, dB | Up to 50 |

| Air Filter | Replaceable HEPA filter |

| Control | 4.7″ color touchscreen |

| Video Camera | Yes |

| Features | • 2 extruders with high-precision cores. • New UltiMaker Cheetah motion planner. • Productivity increased 4 times. • Improved material feed system. • The fastest 3D printer on the market that prints with 2 materials. • Print speed up to 500 mm/s. • Active leveling system, automatic leveling. • Built-in air manager. • Filament presence sensor. • Filament clogging sensor. |

| Supported File Types | UltiMaker Cura: STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG Print formats: G, GCODE, GCODE.gz, UFP |

| Software | UltiMaker Cura, UltiMaker Digital Factory, UltiMaker Essentials. Plugin integration: SolidWorks, Siemens NX, Autodesk Inventor |

| Connectivity | Wi-Fi (2.4 and 5 GHz), Ethernet, USB |

| Power Requirements | 100-240 VAC, 50-60 Hz |

| Power Output | 500W |

| System Requirements | Mac OS, Windows, Linux |

| Warranty Period (months) | 12 |

| Certifications | CE, FCC, VPAT, RoHS, REACH, CB, BIS, KC, PSE, RCM, SRRC, MIC, NCC, safe for professional unattended use. |

| Weight & Dimensions | |

| Weight Netto (kg) | 29,1 |

| Dimensions Assembled (mm) | 495×585×800 |

| Environment Parameters | |

| Operating Temperature Range (°C) | 15 – 32 |

| Operating Humidity Range (%) | Up to 70 |

| Storage Temperature (°C) | 0 – 32 |

3D Printing

Build Speed (mm3/s)

35

Printing Technology

FDM

Layer Height (µm)

60 - 400

Build Volume (mm)

330*240*300

Filament Diameter (mm)

2.85

Number of Extruders

2

Feeder Type

Direct

Nozzle Diameter (mm)

0.25, 0.4, 0.6, 0.8

Maximum Nozzle Temperature (°C)

340

Maximum Bed Temperature (°C)

140

Supported Materials

Tough PLA, PLA, PETG, ABS, CPE, CPE+, Nylon, TPU 95A, PP

Details

Air Filter

Replaceable HEPA filter

Platform Warm-Up Time (min)

Up to 5 (20 to 60 °C)

Heating The Chamber

No

Filament Drying

Optional

Leveling System

Advanced active leveling with more accurate inductive sensors

Maximum Power (W)

500

Positioning Accuracy (µm)

XY: 6.9; Z: 2.5

NFC Filament Sensor

Automatic – NFC scanner

Platform Material

Flexible steel plate with PEI coating

Running Noise, dB

≤ 50

Control

4.7″ color touchscreen

Features

• 2 extruders with high-precision cores. • New UltiMaker Cheetah motion planner. • Productivity increased by 4 times. • Improved material feed system. • The fastest 3D printer on the market, printing with 2 materials. • Print speed up to 500 mm/sec. • Active leveling system, automatic leveling. • Built-in air manager. • Filament presence sensor. • Filament clogging sensor.

Supported File Formats

UltiMaker Cura: STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG Printable formats: G, GCODE, GCODE.gz, UFP

Supported Operating System

Mac OS, Windows, Linux

Software

UltiMaker Cura, UltiMaker Digital Factory, UltiMaker Essentials. Plugin integration: SolidWorks, Siemens NX, Autodesk Inventor

Connectivity

Wi-Fi (2.4 and 5 GHz), Ethernet, USB

Power Requirements

100-240 VAC, 50-60 Hz

Warranty Period (months)

12

Certifications

CE, FCC, VPAT, RoHS, REACH, CB, BIS, KC, PSE, RCM, SRRC, MIC, NCC, safe for professional use without supervision.

Weight and Dimensions

Weight Netto (kg)

29.1

Dimensions Assembled (mm)

495×585×800

Operating Conditions

Operating Ambient Temperature (°C)

15 - 32

Operating Humidity Range (%)

≤ 70

Storage Temperature (°C)

0 - 32