-50 %

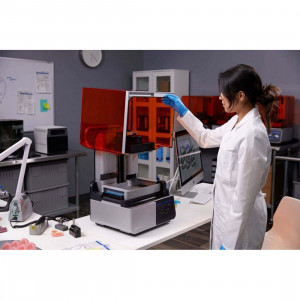

Formlabs Tough 2000 Resin for Form 4, 1L

Formlabs Authorized Partner

3DDevice is an Authorized Partner of Formlabs in Ukraine

Price Incl. VAT

- Stock: In Stock

- Product code: 00-00011140

- Shipping Weight: 1.50kg

- SKU: RS-C2-TO20-11

Based on 0 reviews.

-

Write a comment

₴5 940.00

₴11 821.00

Ex Tax: ₴5 940.00

Quantity:

High-strength Tough 2000 Resin for Form 4

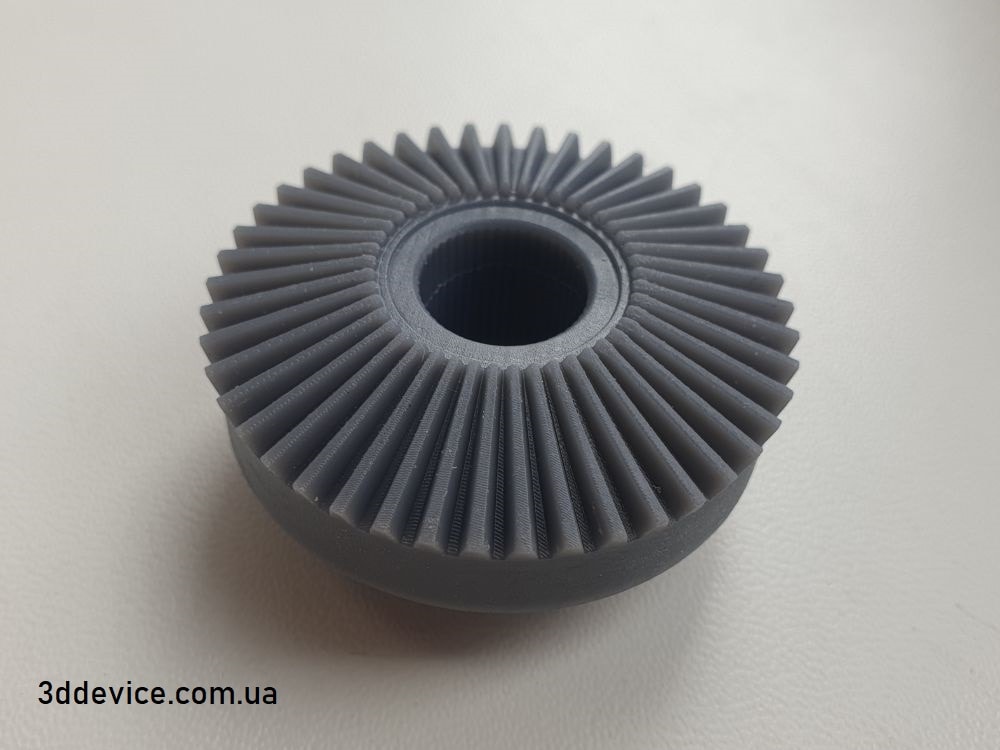

Tough 2000 Resin for Form 4 3D printer has the same strength and rigidity as ABS plastic. It is an ideal material for printing functional and durable finished products and prototypes that are difficult to bend.

Choose Tough 2000 Resin for prototyping robust and reliable parts that must not bend easily, as well as fixtures and attachments that require minimal deflection.

Why choose Tough 2000 Resin?

Tough 2000 Resin is a functional material that is difficult to bend and will hold up over time.

- Tough and durable. Build strong parts with minimal deformation.

- Resistant. Withstand intermittent or constant loads required for heavy parts.

- Aesthetic, neutral color. Create professional-looking parts that blend seamlessly into the environment.

- Durable. Iterate with greater confidence and reduce brittle failures.

Where Tough 2000 is used

Tough 2000 Resin is ideal for rugged prototyping or simulating the strength and rigidity of ABS. Choose Tough 2000 Resin for:

- Fixtures and jigs that require minimal deflection.

- Strong and stiff prototypes.

- Manufacturing aids.

- Enclosures and housings.

Specifications

| Printing technology | SLA |

| Polymerization | Necessary |

| Ultimate tensile strength | 46 MPa |

| Tensile modulus | 2.2 GPa |

| Elongation | 48% |

| Flexural Modulus | 1.9 GPa |

| Notched Izod | 40 J/m |

| Heat Deflection Temp @ 0.45 MPa | 63 ºC |

| Layer height (micron) | Form 4/4B – 50, 100 |

| Printer Compatibility | Form 4/4B |

| Resin Tank Compatibility | Form 4 Resin Tank |

| Build Platform Compatibility | Form 4 Build Platform, Form 4 Build Platform Flex |

| Volume (L) | 1 |

| Manufacturer Country | USA |

Buy Tough 2000 Resin for Form 4 3D Printer

3D Printing

Printing Technology

MSLA

Layer Height (µm)

Form 4/4B – 50, 100

Details

Polymerization Needed

Yes

Printer Compatibility

Form 4/4B

Resin Tank Compatibility

Form 4 Resin Tank

Build Platform Compatibility

Form 4 Build Platform, Form 4 Build Platform Flex

Volume (L)

1.0

Country of Brand Registration

USA