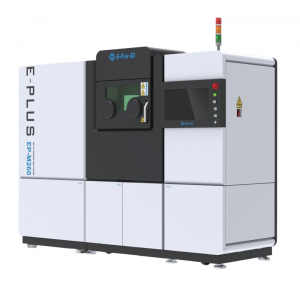

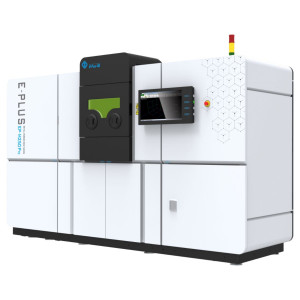

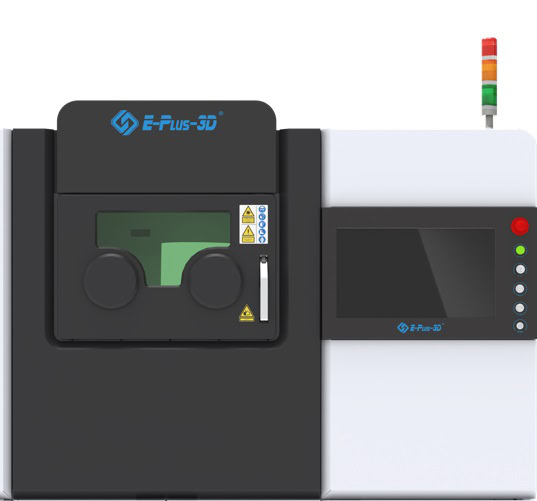

3D printer SLM E-PLUS 3D EP-M260

- Stock: In Stock

- Product code: GEN-86368795

- Shipping Weight: 2,760.00kg

Based on 0 reviews.

-

Write a comment

₴0.00

Ex Tax: ₴0.00

Quantity:

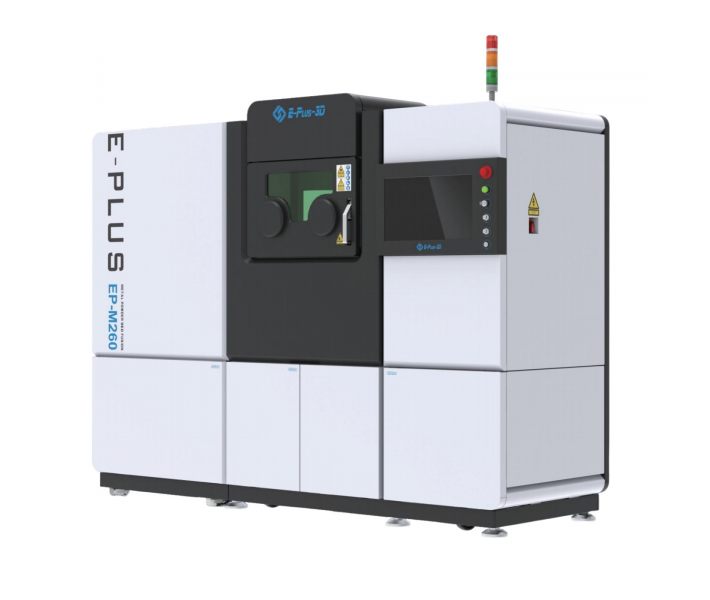

SLM 3D metal printer EP-M260

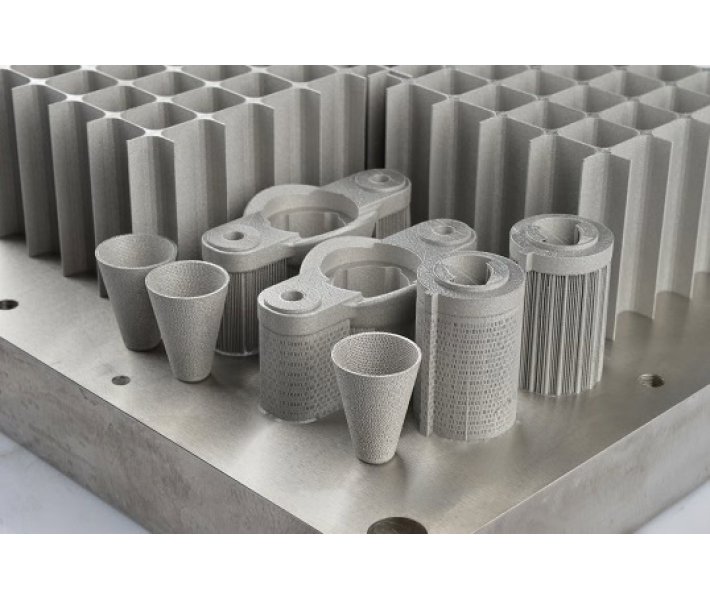

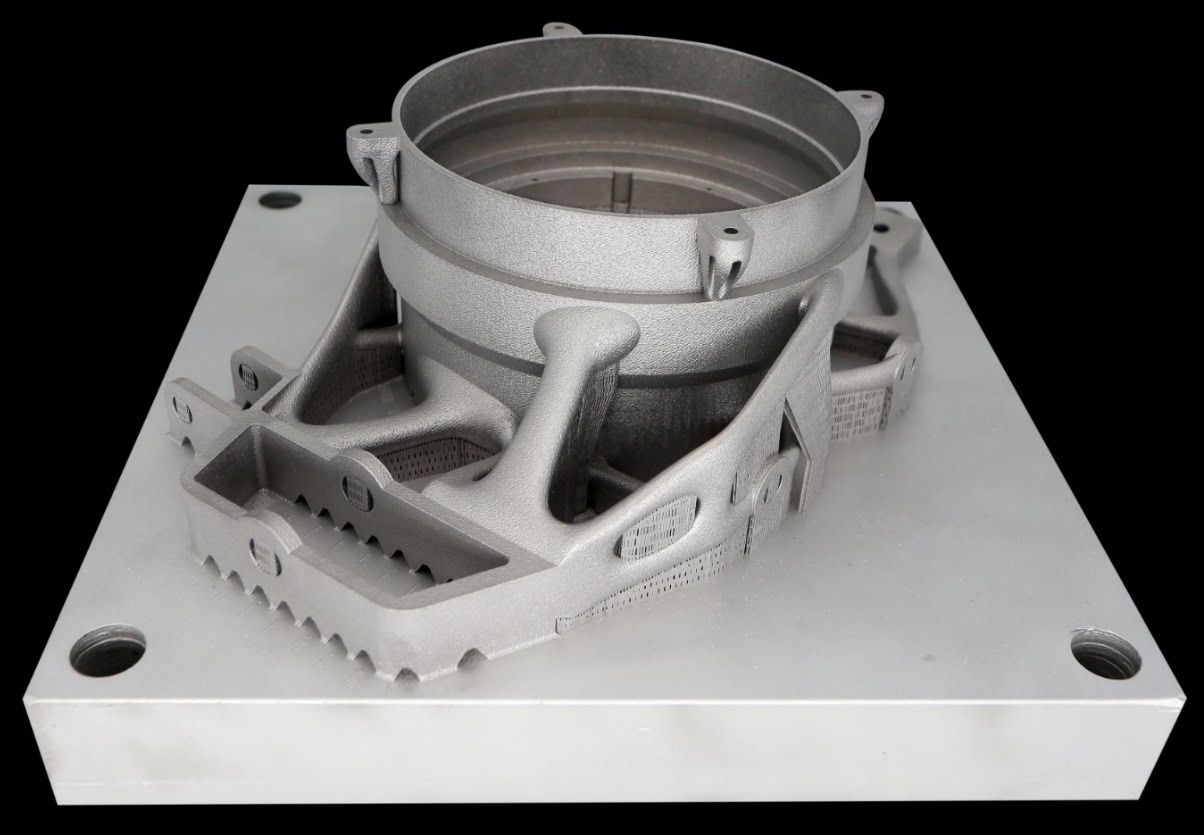

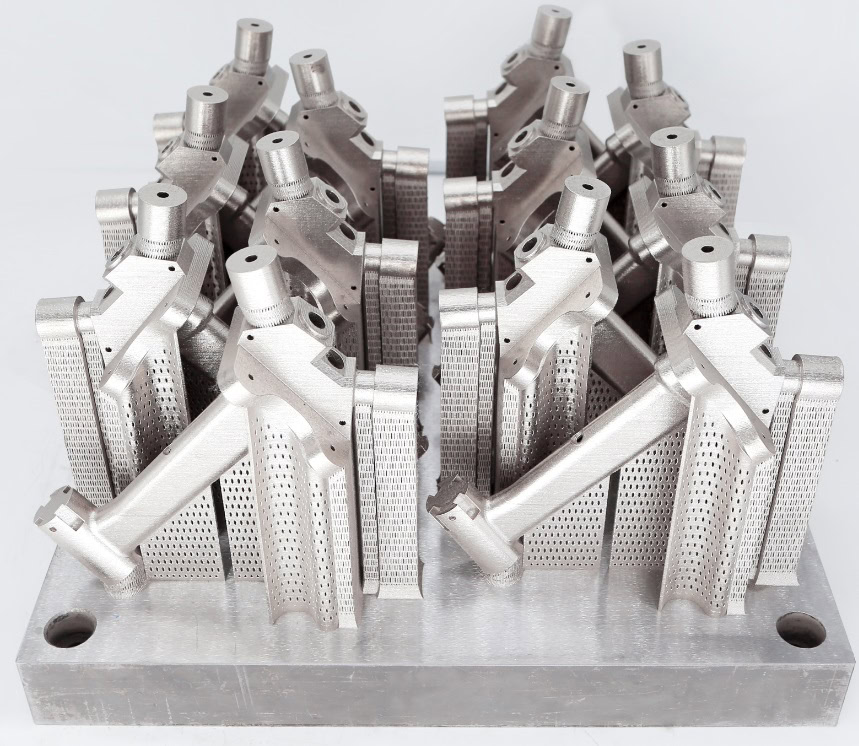

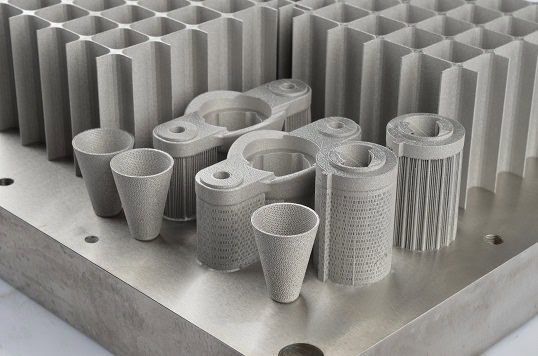

In the 3DDevice online store you can buy the EP-M260 metal 3D printer, which offers highly efficient and large-scale production from metal powder.

This is an industrial 3D printer that was created on the basis of the previous generation EP-M250 and received a number of new features and improvements for safer and more convenient production of high-quality metal parts from powdered metal materials.

Main features

- Build size – 260*260*390 mm.

- Power – 500 / 700 W (one or a pair of lasers to choose from).

- Optimized re-coating strategy reduces coating time.

- Software: EPControl, EPHatch.

High technology for high performance

- Innovative gas flow control and an optimized filter system ensure a stable working environment.

- The perfectly sealed chamber optimizes the oxygen content.

- Precise quality control of the laser beam.

High productivity

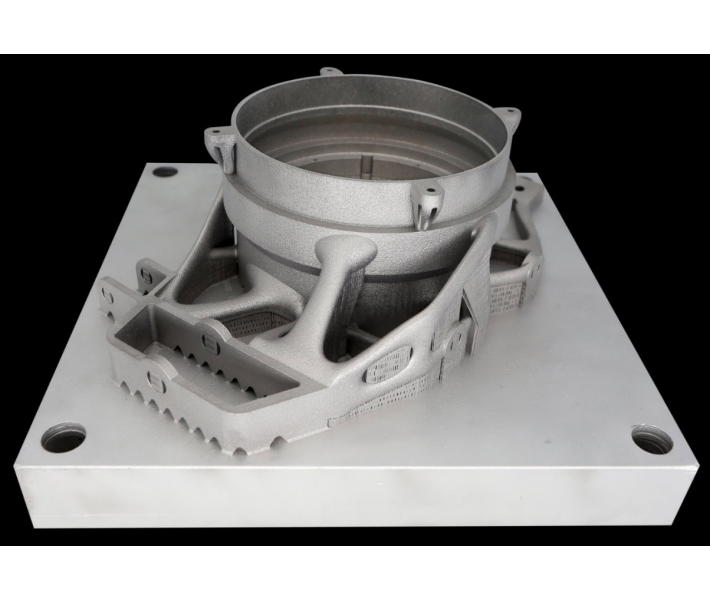

- Dual laser system equipped with a 260*260*390 mm collection chamber.

- Does not interrupt work during filter change.

- Optimized recoating strategy reduces coating time.

Reliable and easy operation

- Convenient powder handling systems and a glove access structure minimize contact with the powder.

- Intelligent software ensures less human intervention.

- Real-time monitoring of the production environment and construction process.

Low cost of operation

- Quantitative powder feeding and coating ensure less powder waste.

- Advanced filtration system significantly increases filter life.

- Low inert gas consumption during purging and operation.

Safe internal access through gloves

- Intelligent electronic lock without manual operation.

- Double mechanical lock for increased security.

- Signal when the access door is opened abnormally to increase the safety of use.

- Double-handle access door design allows operation without opening the door.

- Tension seal with good sealing performance, can be controlled both automatically and manually.

What’s new in the EP-M260 metal printer?

Comparison with the previous model EP-M250:

| Feature | EP-M250 | EP-M260 |

|---|---|---|

| Build Volume (X*Y*Z) | 258*258*350 mm | 260*260*390 mm, larger building volume |

| Wind field | – | Re-adjusted wind field to ensure uniform wind field across the entire print area and consistent printing performance |

| Gas circulation filtration system | – | Increase the function of blowing back dust during printing |

| Galvanometer | – | Re-adjust the structure of the galvanometer to ensure that the temperature is uniform and stable, so that the laser will not have thermal drift |

| Industrial computer operation mode | Mouse | Touch screen |

| Gas circuit modification | – | Ensure that the chamber pressure is stable at about 25mbar |

| Fan | High pressure fan | High pressure fan + Vacuum pump (Shorten the inflation time) |

| Grating ruler | – | Increase the grating ruler to make the Z-axis repeat positioning accuracy more accurate |

| Passivator | – | Use passivator to ensure safety when replacing the filter element |

| Powder bucket | – | The powder bucket can be filled with protective gas in advance to ensure that no air oxygen enters the cabin when the powder bucket is replaced during the printing process |

| Filtration system | Normal filtration system | Upgraded to permanent filtration system, not only extending the service life of the filter but also avoiding risks of replacing the filter. |

| Self-developed software | – | Optimized data preparation software EP-Hatch |

Technical characteristics

| Machine Model | EP-M260 |

| Build Volume (X*Y*Z) (height incl. build plate) | 260*260*390 mm |

| Optical System | Fiber Laser 500 W / 700 W (single or dual-laser optional) |

| Spot Size | 70 – 100 μm |

| Max Scan Speed | 8 m/s |

| Theoretical Printspeed | Up to 55 cm³/h |

| Layer Thickness | 20 – 120 μm |

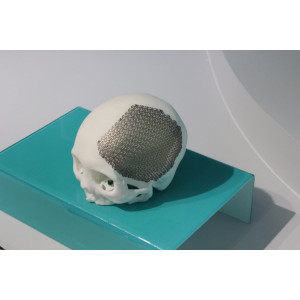

| Material | Titanium Alloy, Aluminum Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome, Copper Alloy, etc. |

| Power Supply | 380 V, 50 / 60 Hz, 5 / 6 kW |

| Gas Supply | Ar / N₂ |

| Oxygen content | ≤ 100 ppm |

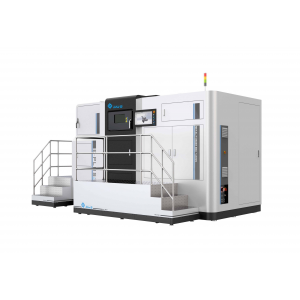

| Dimension (W*D*H) | 2800*1300*2410 mm |

| Weight | 2300 kg |

| Software | EP Control, EPHatch |

| Input Data Format | STL or other Convertible File |

Service and warranty information

Training

- Training (including software training, operation training, safety training, maintenance training, etc.) for technicians or engineers: Technicians from our subsidiary in Germany provide on-site training for your engineers when the first metal printer is required to be installed. It usually takes 5 working days for installation and on-site training (Poland only).

- Our professional technicians can provide remote training for engineers of customers from Ukraine before installation. After that, our technicians can also offer you remote installation.

Warranty

- The standard warranty period is one year.

- During this period, our technical team provides free online support for daily operation.

- If the printer’s wear parts or components encounter problems during normal operation, the manufacturer will offer free replacement parts.

- If problems cannot be resolved through remote support, the company can send technicians to the customer’s site.

- After the warranty period, regular maintenance of the equipment is recommended.

- We recommend regular maintenance of the equipment to ensure that it is working properly, and the recommended interval between each maintenance is 1 year.

- Usually, regular system maintenance is performed by our specialists, and they will provide you with a detailed maintenance report after the service is completed.

To clarify the price of maintenance, please contact your manager.

Buy a metal 3D printer in Ukraine at an affordable price

Printer Settings

Printing Accuracy (µm)

70 - 100

3D Printing

Build Speed (cm3/h)

Up to 50

Printing Technology

SLM

Layer Height (µm)

20 - 120

Build Volume (mm)

260*260*390

Details

Inert Gas Consumption

Ar / N₂

Supported Materials

Titanium alloy, aluminum alloy, nickel alloy, martensitic steel, stainless steel, cobalt chromium, copper alloy and more.

Control

Touch-screen

Software

EP Control, EPHatch

Power Requirements

380 V, 50 / 60 Hz, 5 / 6 kW

Country of Origin

China

Warranty Period (months)

12

Weight and Dimensions

Weight Netto (kg)

2300

Dimensions Netto (mm)

2800*1300*2410