Description

Creaform HandyPROBE™ next Elite Handheld Optical Coordinate Measuring Machine

The HandyPROBE next Elite handheld optical system, or optical coordinate measuring machine (CMM), is designed for precise measurements in industrial environments.

Unlike traditional stationary CMMs, this device does not require rigid mounting in one place. However, if necessary, the operator can place the HandyPROBE on a tripod, which is included in the delivery package.

The system is designed for operation in production conditions. It guarantees high measurement accuracy and dynamic referencing, which allows obtaining stable and reliable results regardless of external factors and the operator’s skill level.

How does the Creaform HandyPROBE™ work?

The HandyPROBE is equipped with a two-dimensional C-Track sensor that simultaneously captures the position of the reference model and the probe. The device combines advanced photogrammetry technologies with powerful digital image processing, ensuring maximum measurement accuracy.

The system is designed for industrial inspection, so it can be used directly in the workshop without moving parts to a measuring laboratory.

The HandyPROBE next Elite helps engineers monitor product parameters, measure dimensions, and verify the accuracy of part manufacturing. Thanks to the optical system and wireless connection, measurements are taken quickly and conveniently, even if the object or instrument moves slightly during operation.

Key Features of the HandyPROBE™ next Elite

- High measurement accuracy – up to 0.025 mm

- Volumetric accuracy – 0.064 mm

- Part size range – 0.2–6 m

- Probe weight – 0.5 kg

- C-Track weight – 5.7 kg

- Acceptance testing complies with the ISO 10360-12 standard.

- ISO 17025 accreditation.

Ease of Use Guarantees High Productivity

- Wireless technology – no cable connection required

- Flexibility in operation – suitable for objects of various sizes and shapes

- Resistance to external conditions – vibrations and temperature changes do not reduce accuracy

- Ease of use – simple setup, no lengthy training required

- Mobility – the lightweight device can be easily moved and used in different work areas

- The ergonomic wireless probe with multi-function buttons ensures convenient operation.

- High measurement accuracy even in conditions of vibration and unstable environment.

- Reflectors attached to the part create a reference point that compensates for any accidental movements.

- The HandyProbe dynamic referencing mode constantly tracks the object’s position, ensuring measurement stability.

- The handheld stylus, connected to the C-Track wirelessly, makes the measurement process even more convenient.

- Free movement of the operator around the part without cable restrictions.

Main Applications of the HandyPROBE™ next Elite Optical System

Quality Control and Geometry Verification

The HandyPROBE helps perform industrial control and verify the accuracy of part manufacturing. The system compares the actual dimensions of the object with its digital 3D model (CAD), which allows to:

- Identify deviations and defects.

- Control the dimensional parameters of parts.

- Analyze the accuracy of shapes and surfaces.

- Compare finished products with design documentation.

This allows for prompt correction of production processes and elimination of defects.

Reverse Engineering

The HandyPROBE is used to create digital copies of existing parts. This is relevant in the following cases:

- Recreating obsolete components for which drawings are missing

- Developing new parts based on existing objects

- Optimizing designs to improve their characteristics

The HandyPROBE technology allows obtaining accurate measurements of the object’s coordinates and converting them into a 3D model for further design.

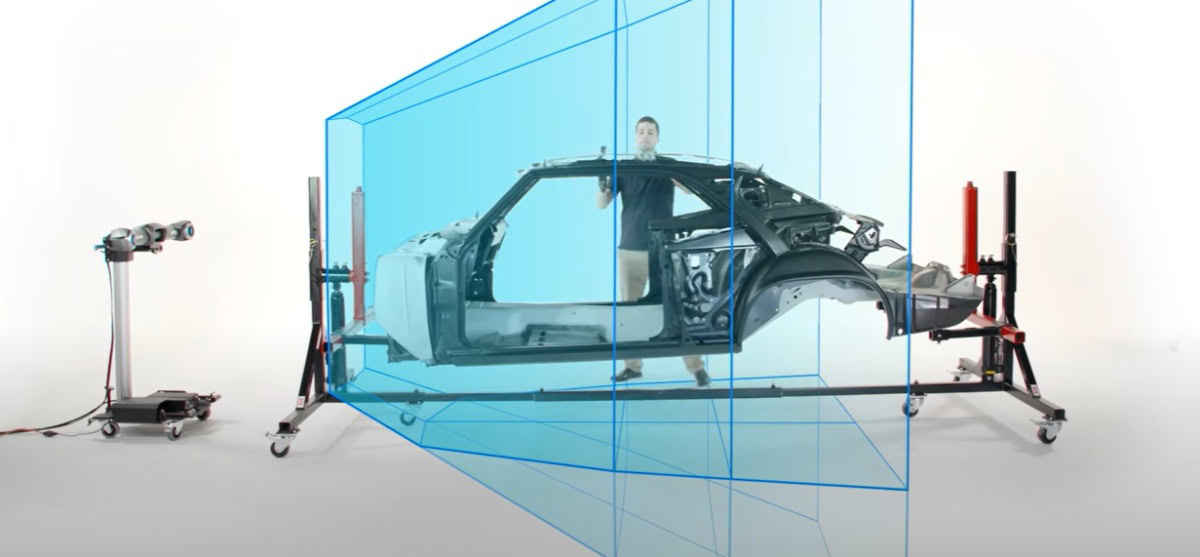

Measurements in the Production Process

Unlike traditional CMMs, the HandyPROBE can be used directly in the workshop. This greatly simplifies the control of part parameters directly during production, rather than after its completion.

Advantages of this technology:

- Eliminating the need to transport parts to the laboratory.

- Possibility of industrial control in real conditions.

- Quick identification of problems before assembly is complete.

Calibration and Alignment of Large Parts

The HandyPROBE allows aligning and precisely positioning large objects. This is especially important when assembling complex structures such as:

- Car bodies

- Aircraft parts

- Industrial mechanisms

The system helps to fit elements with high accuracy, which reduces the likelihood of errors during assembly.

Assembly Control and Part Fitting

The HandyPROBE next Elite is used to evaluate the accuracy of part joining. This is necessary for:

- Verifying the correct assembly of complex units

- Adjusting gaps between elements

- Controlling the parameters of finished structures

The device helps to ensure that the final product meets design requirements.

Why is the HandyPROBE™ the Best Choice for Precise Measurements in Workshops?

- Does not require rigid mounting – the device and object can be moved freely.

- Suitable for various tasks – measures objects of any size.

- Not afraid of vibrations – accuracy is maintained even in difficult conditions.

- Does not require lengthy calibration – ready to work immediately after switching on.

The Creaform HandyPROBE™ is a modern solution for precise measurements that replaces traditional stationary CMMs. Thanks to its flexibility, mobility, and high accuracy, the device is widely used in the aerospace, automotive, and mechanical engineering industries.

The HandyPROBE helps speed up production processes, minimize errors, and ensure effective industrial control. This guarantees stable product quality and compliance with high standards.

Buy a portable optical system for production in Kyiv Creaform HandyPROBE Next

Reviews

There are no reviews yet.