- Stock: Inquire availability

- Product code: GEN-23594244

- Shipping Weight: 1.20kg

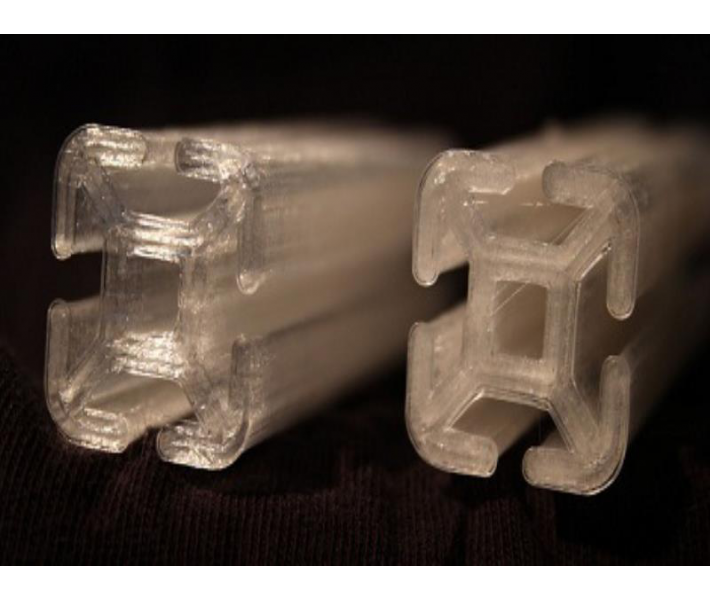

Polycarbonate for 3D printers

Polycarbonate is primarily interesting for its high transparency, thanks to which it is often used as a substitute for glass. And thanks to the high strength of the material, polycarbonate is even used to make bulletproof glass. Otherwise, polycarbonate is used to manufacture food containers, protective equipment, compact discs, etc. This plastic is quite heat-resistant and can withstand temperatures ranging from -40 to 120 °C. At the same time, polycarbonate is not resistant to most chemical and organic solvents, including chloroform, ethylene chloride, meta-cresol, tetrachloroethane, and others.

The friction coefficient of the material is quite high, and, in addition, the plastic has good strength and resistance to mechanical stress. It can be sterilized, is fire-resistant, and has excellent dielectric properties. The disadvantages of the material include:

- High hygroscopicity. Polycarbonate easily absorbs moisture, so it should be stored in vacuum packaging or in dry places. When moistened, the plastic loses its transparency and becomes whitish-matte;

- This plastic is vulnerable to UV light. Over time, with prolonged exposure, it can lose its strength and become brittle.

- Release of toxic substances during printing. Although the material is environmentally friendly, aggressive substances are used in its production, the residues of which are released when polycarbonate is melted.

Polycarbonate. Printing features

Polycarbonate printing technology is not much different from working with standard PLA and ABS plastics. The filament diameter is standard and available in two variations – 1.75 mm and 3 mm. A nice bonus is the material's compatibility with other plastics, which opens up the possibility of manufacturing prefabricated structures.

It is best to print with polycarbonate on a heated platform using a substrate in a temperature range of 90 to 120 °C. For high-quality reproduction of the model, the following printing parameters are recommended:

| Printing parameters | Values |

| Printing temperature | 260 – 285 °C |

| Platform temperature | 90 – 120 °C |

| Blowing | without blowing |

| Printing speed | 30 – 60 mm/s |

| Cooling shrinkage | 0,5 – 0,7 % |

It is also important to note that the printing speed of the material depends on the extruder temperature.

- At a printing speed of 30 mm/s, a temperature of 265 °C is sufficient, although even at a temperature of 255 °C, the extruder does not clog with plastic.

- At a printing speed of 60 mm/s, the minimum printing temperature is 285 °C.

- The recommended temperature at a printing speed of 80 mm/s is 295–300 °C.

- At a printing speed of over 120 mm/s, it is recommended to increase the temperature to 305 °C or higher (lower temperatures can lead to cracks and breaks).

Technical specifications

| Filament diameter, mm | 1.75/3.00 +/-0.05 |

| Ovality, mm | +/-0.03 |

| Density, kg/m3 | 1200 |

| Melting point, °С | 250 |

| Linear mass, m/kg (length of 1 kg of monofilament) | 370 |

| Bending resistance, times | 50 |

| Printing technology | FDM |

| Color white | білий |

| Plastic diameter | 1,75 мм |

| Internal spool diameter | 32 mm, 37 mm, 57 mm |

| Country of manufacture | Ukraine |

Mechanical characteristics

| Characteristics | ASTM definition | Units |

| Tensile modulus, not less than | D-638 | 2600 MPa |

| Tensile strength, not less than | D-638 | 52 MPa |

| Elongation, not less than | D-638 | 290 % |

| Density | D-792 | 1,20 g/cm3 |

| Notched Izod impact strength (23 °C) | D-256 | 90 kJ/m2 |

| Light transmission | 89 % | |

| Water absorption | 0,2 % |