- Stock: In Stock

- Product code: 00-00012682

- Shipping Weight: 2.00kg

- SKU: F-MF-0001

Markforged Onyx 800cc – composite material for strong and precise parts

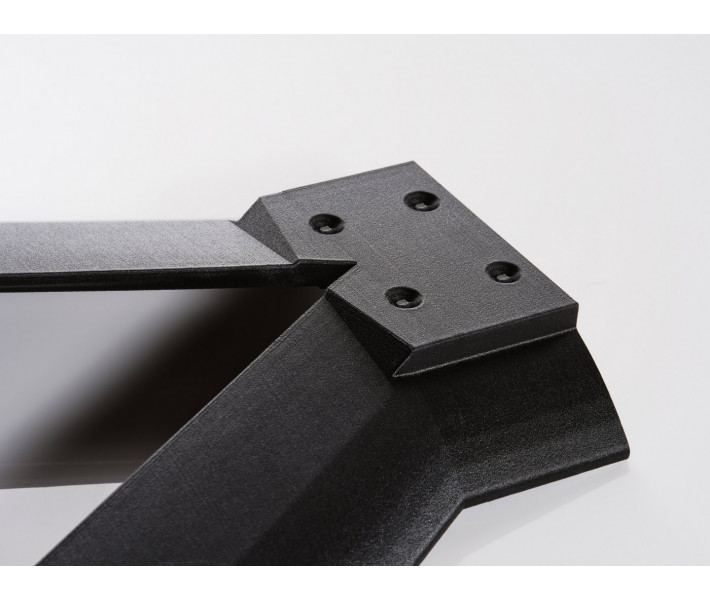

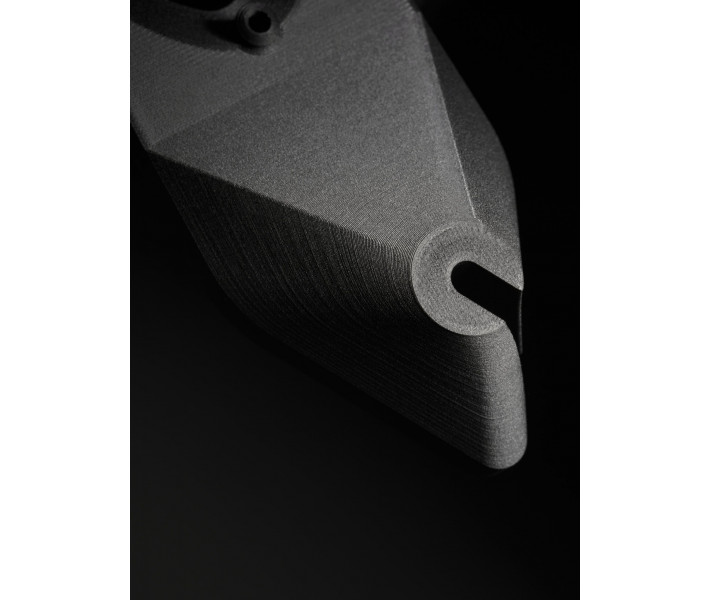

The Markforged Onyx 800cc filament is the flagship filament of Markforged, made from nylon with the addition of carbon microfibers. The combination of these components provides high stiffness, excellent printing accuracy, and load resistance. Thanks to its unique structure, this Onyx filament for 3D printing has become the foundation for creating millions of parts used in industry, engineering, and manufacturing.

Main characteristics of Onyx 800cc

- Material – nylon with microcarbon fibers

- Color – black, with a matte finish

- Flexibility in application – used alone or with reinforcing fibers (carbon, Kevlar, fiberglass, high-temperature fiberglass)

- Bending strength – 71 MPa

- Heat resistance – up to 145 °C

- Spool volume – 800cc

The Markforged Onyx filament allows for the production of precise parts with an excellent surface finish without additional processing, which is especially valued in the production of finished components.

Compatibility and capabilities

Onyx 800cc for 3D printers is compatible with the entire range of Markforged composite printers, including FX20, FX10, X7, Mark Two, Onyx Pro, as well as X3 and X5. Its versatility makes it an indispensable material for companies looking for a balance between strength, accuracy, and printing efficiency.

Applications

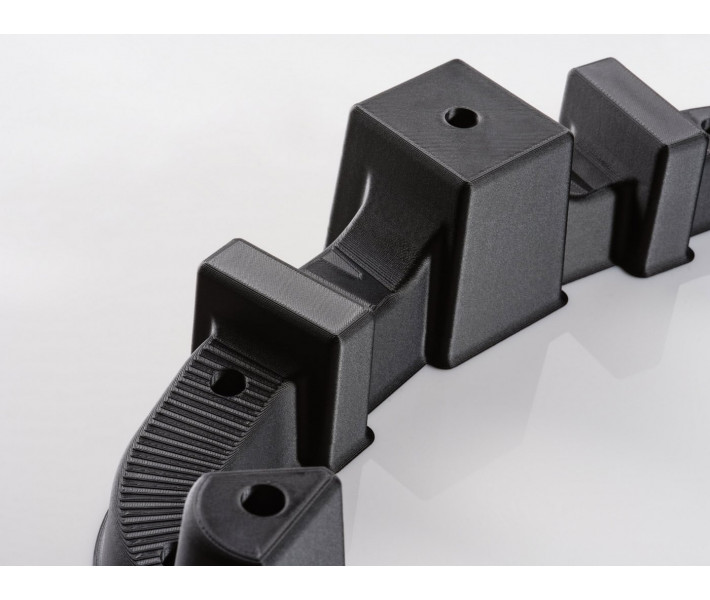

The filament for industrial 3D printing is used for manufacturing:

- housing parts and mounts

- high-precision prototypes

- sensor and electronic mounts

- tools and equipment for production

- end parts that operate under load

Additionally, when combined with continuous fibers, Onyx becomes the basis for parts with strength comparable to aluminum. This opens the way for the production of complex structures that combine lightness and extraordinary strength.

Advantages of Markforged Onyx 800cc

Markforged Onyx 800cc is a reliable and time-tested material that provides a balance between surface quality, high strength, and versatility of application. Using it in combination with Markforged Onyx Pro and X7 technologies, you will obtain parts that meet the highest standards of modern manufacturing.

This composite material from Markforged has several advantages over classic polymer filaments:

- high strength and stiffness due to carbon microfibers

- excellent appearance without additional finishing

- resistance to chemical exposure and elevated temperatures

- flexibility in use – both alone and with reinforcement

- optimal solution for producing prototypes and serial parts

Thanks to these characteristics, carbon fiber material for 3D printing is used in various industries: from machine engineering and aerospace to electronics and the manufacture of specialized equipment.

Buy Markforged Nylon microcarbon composite in Ukraine

Order the composite 3D printing material Markforged Onyx 800cc at the 3DDevice. We have been operating since 2012, have expert experience in the field of 3D printing, and will help you select the optimal material for your specific tasks.

3D Printers

- Metal X

- FX10

- FX20

- X7 (Gen 2)

- X7 (Gen 2) Field Edition

- X7 (Gen 2) Field Edition Brochure

- Mark Two (Gen 2)

- Onyx Pro (Gen 2)

Additional Equipment

Materials

Metal

Markforged Metal Filaments combine the simplicity and safety of FFF printing with the superior properties of advanced metals, bringing metal 3D printing to your benchtop.

- 17-4PH Stainless Steel

- 316L Stainless Steel

- Copper

- H13 Tool Steel

- Inconel 625

- A2 Tool Steel

- D2 Tool Steel

Plastics

Composite Base filaments are engineering-grade materials that print using a conventional FFF (FDM-style) process. Print with them alone or with Continuous Fibers to yield strong parts. The ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.

Continuous Fiber

Continuous Fibers enable Markforged composite printers to print metal-strength parts. They cannot be used alone — however, when printed with a Composite Base, they form the backbone of a strong printed part.