- Stock: In Stock

- Product code: 00-00013287

- Shipping Weight: 2.30kg

- SKU: F-MF-1010

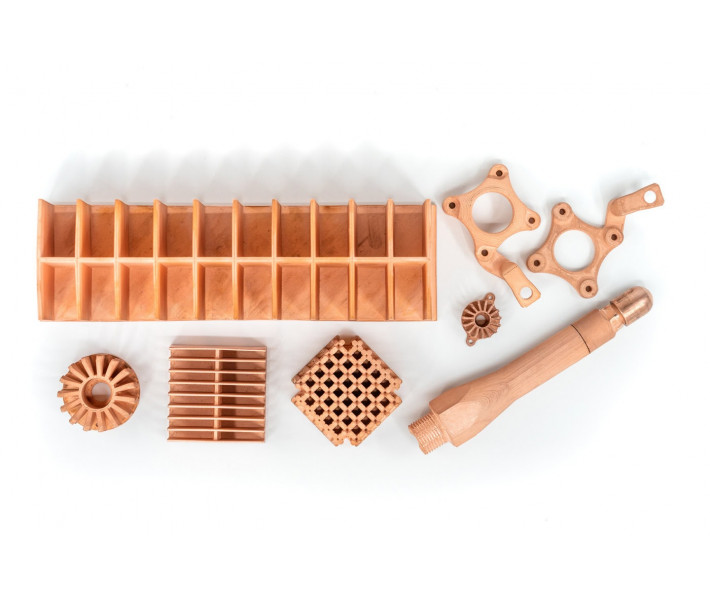

Markforged Copper 200cc – high-conductivity copper for innovative 3D printing

The Markforged Copper 200cc filament is a unique material for professional 3D printing, designed for those who require maximum thermal and electrical conductivity in their products. With a purity of 99.8% Cu, this Markforged copper material allows for the production of functional parts with characteristics that cannot be achieved using standard metal alloys.

Advantages of using Copper from Markforged

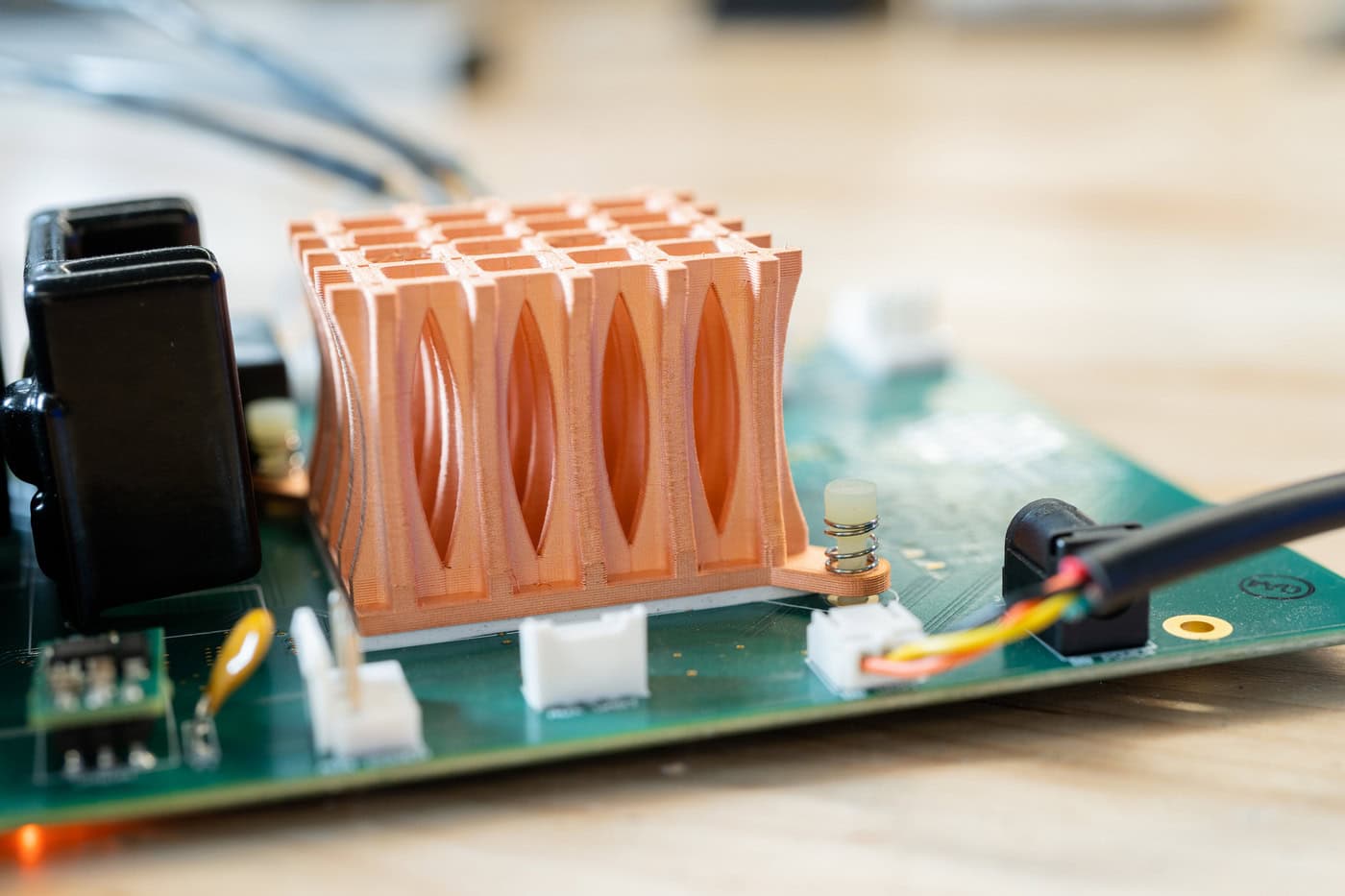

Unlike traditional machining, copper for Metal X allows for the production of components with complex geometries without additional costs for machining. This opens the way to creating elements that were previously almost unattainable in conventional manufacturing.

Among the main advantages:

- high printing accuracy and repeatability of results

- ability to create complex structures with internal channels

- time and resource savings compared to classical machining methods

- access to professional production of parts in your own workshop

Why choose copper filament for 3D printing?

Copper is known for its ductility and excellent machinability. In traditional manufacturing, it is complex and expensive to produce; however, 3D printing technology with copper allows for the creation of precise and complex-shaped parts without unnecessary costs and limitations. Using Markforged Copper filament, you can produce:

- welding tails and brackets

- induction coils

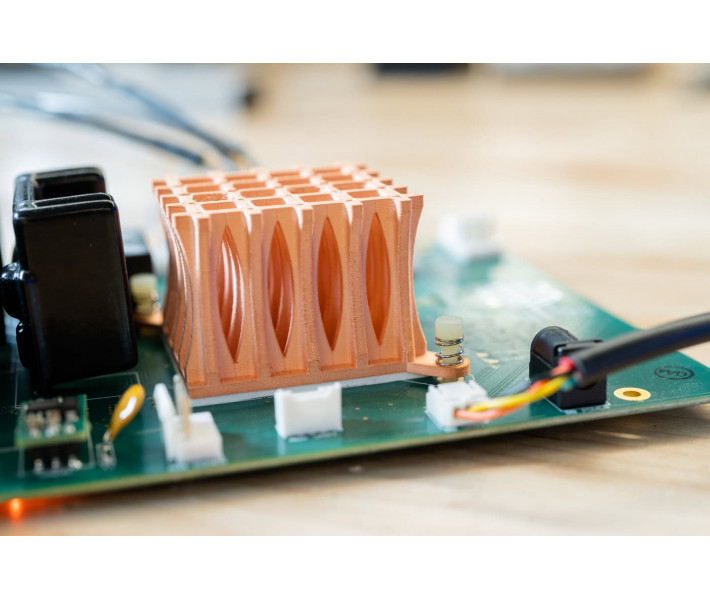

- radiators and heat exchangers

- complex geometry shapers

- special adapters and fittings

- electrodes for electrical discharge machining

- antennas and other electrical components

Compatibility

The copper filament is fully compatible with the metal printing system Markforged Metal X.

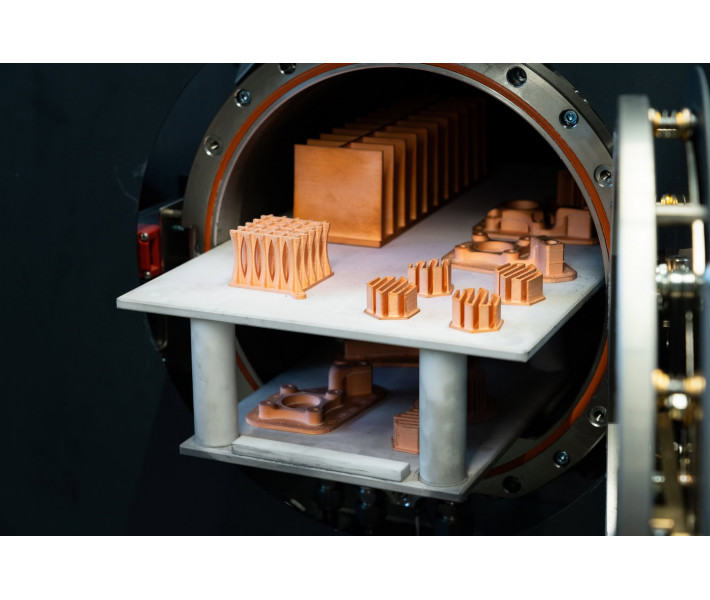

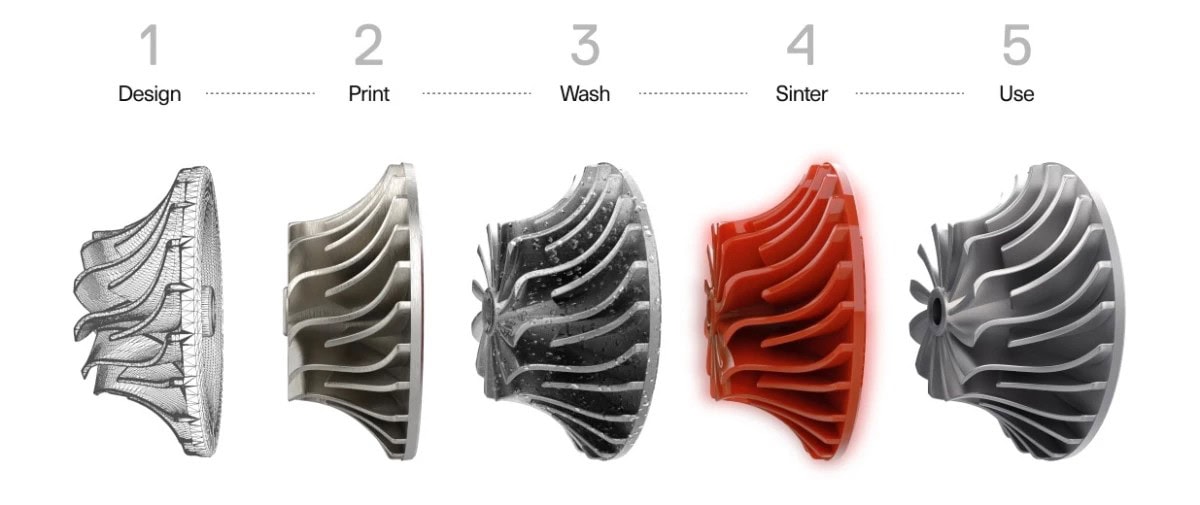

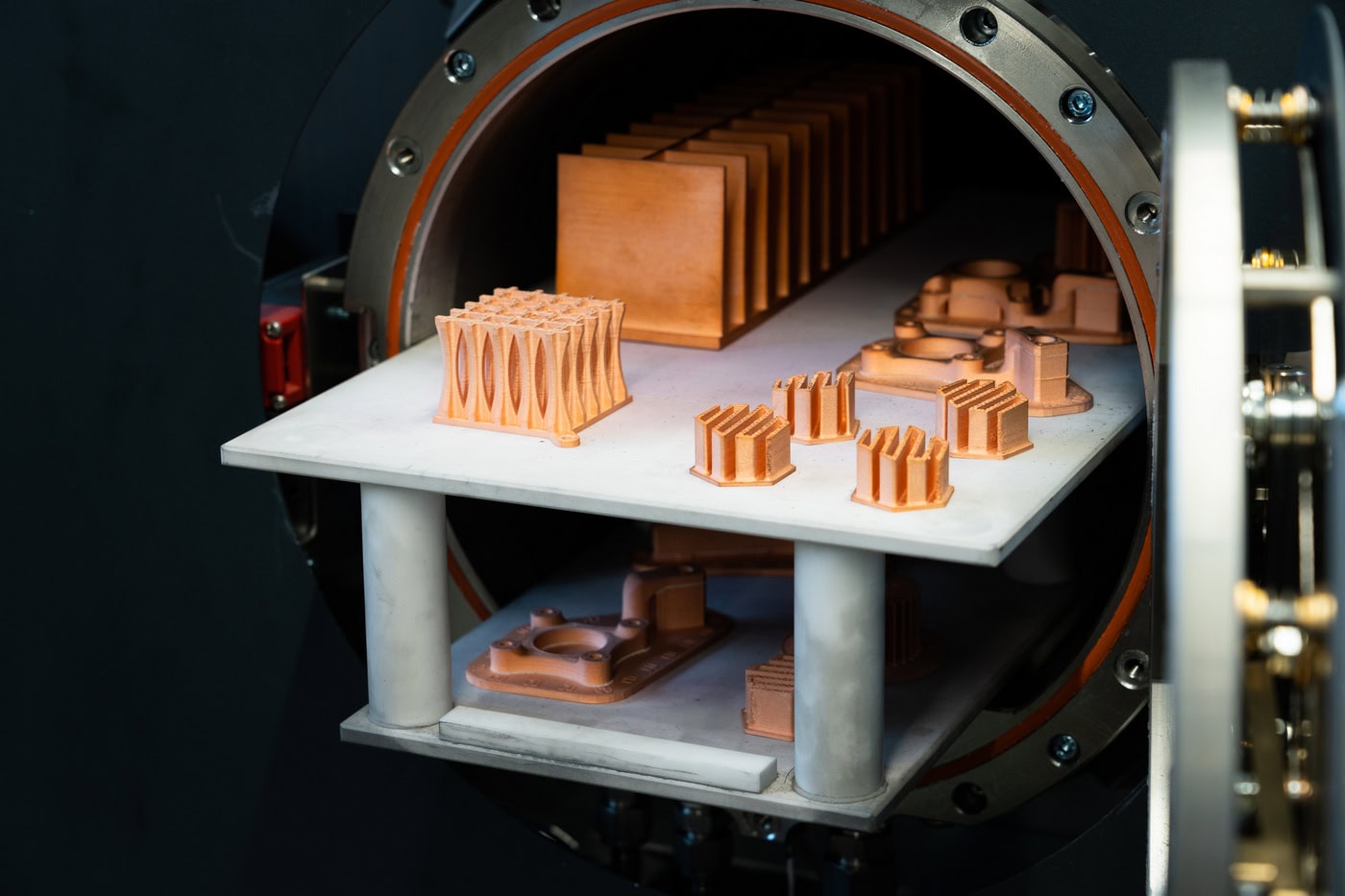

ADAM Manufacturing Technology

The process of manufacturing parts from this material is based on ADAM (Atomic Diffusion Additive Manufacturing) technology. The essence of the technology is that stainless steel powder is contained in a polymer binder, which is fed into the nozzle based on the principles of classic FDM printing. The subsequent sintering process leads to atomic diffusion, resulting in a fully metal part with excellent mechanical properties.

Technical Specifications

The filament is presented in the form of a spool with a volume of 200 cc. It is compatible with the Metal X system, ensuring a simple and reliable working process.

- Electrical conductivity – 84% IACS in sintered form

- Thermal conductivity – 350 W/mK in sintered form

- Material purity – 99.8% copper (Cu)

These indicators make the 200cc copper filament an optimal choice for high-tech fields where effective heat transfer and stable electrical conductivity are important.

Where is Markforged Copper filament used?

The material is widely used in electrical engineering, energy, construction, and engineering industries. It is chosen for the production of heat exchangers, cooling system components, electrical connections, inductors, and specialized industrial parts.

Due to its properties, the material for the Markforged 3D printer becomes indispensable in areas where reliability, conductivity, and durability are critically important.

Buy Markforged copper filament in Ukraine

Choose Markforged Copper filament from us – the official representative of Markforged in Ukraine.

We are professionals in the field with over 10 years of experience in 3D printing, providing expert consultations and helping you select the optimal material for your tasks. By purchasing from us, you receive an original product and complete confidence in its quality.

3D Printers

- Metal X

- FX10

- FX20

- X7 (Gen 2)

- X7 (Gen 2) Field Edition

- X7 (Gen 2) Field Edition Brochure

- Mark Two (Gen 2)

- Onyx Pro (Gen 2)

Additional Equipment

Materials

Metal

Markforged Metal Filaments combine the simplicity and safety of FFF printing with the superior properties of advanced metals, bringing metal 3D printing to your benchtop.

- 17-4PH Stainless Steel

- 316L Stainless Steel

- Copper

- H13 Tool Steel

- Inconel 625

- A2 Tool Steel

- D2 Tool Steel

Plastics

Composite Base filaments are engineering-grade materials that print using a conventional FFF (FDM-style) process. Print with them alone or with Continuous Fibers to yield strong parts. The ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.

Continuous Fiber

Continuous Fibers enable Markforged composite printers to print metal-strength parts. They cannot be used alone — however, when printed with a Composite Base, they form the backbone of a strong printed part.