- Stock: In Stock

- Product code: 00-00013293

- Shipping Weight: 4.50kg

- SKU: 22474

Stainless steel with enhanced corrosion resistance

The Markforged 316L Stainless Steel filament is a low-carbon austenitic stainless steel that combines high strength, impact resistance, and exceptional corrosion resistance. It is widely used in the food industry, automotive manufacturing, chemical production, medical field, and marine environment.

Why choose Markforged 316L Stainless Steel Filament for 3D printing?

This material provides an optimal balance between mechanical properties and durability. Due to its low carbon content and high corrosion resistance, 316L stainless steel for 3D printing is ideal for parts that operate in aggressive conditions.

Key advantages include:

- resistance to acids, salts, and seawater

- durability and stability of properties in challenging operating conditions

- good combination of strength and ductility

- ability to produce functional prototypes and industrial-grade finished parts

Areas of application

The Markforged 316L Stainless Steel filament opens up opportunities for the production of components where corrosion resistance is important.

Among the most common areas:

- food industry

- marine industry and shipbuilding

- chemical and petrochemical production

- medical devices and implants

- automotive industry

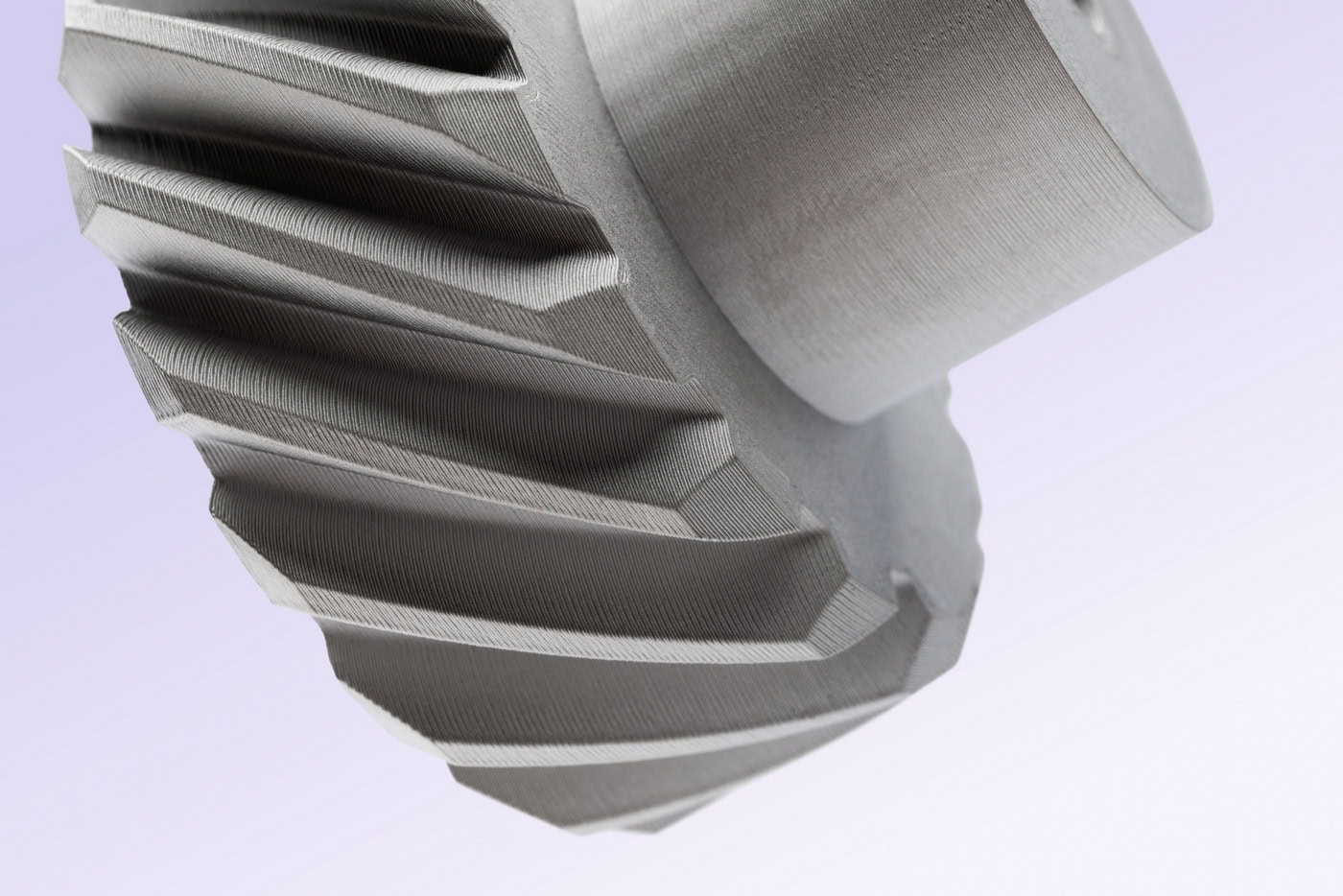

- machinery and engineering

Typical applications include the production of:

- end effectors

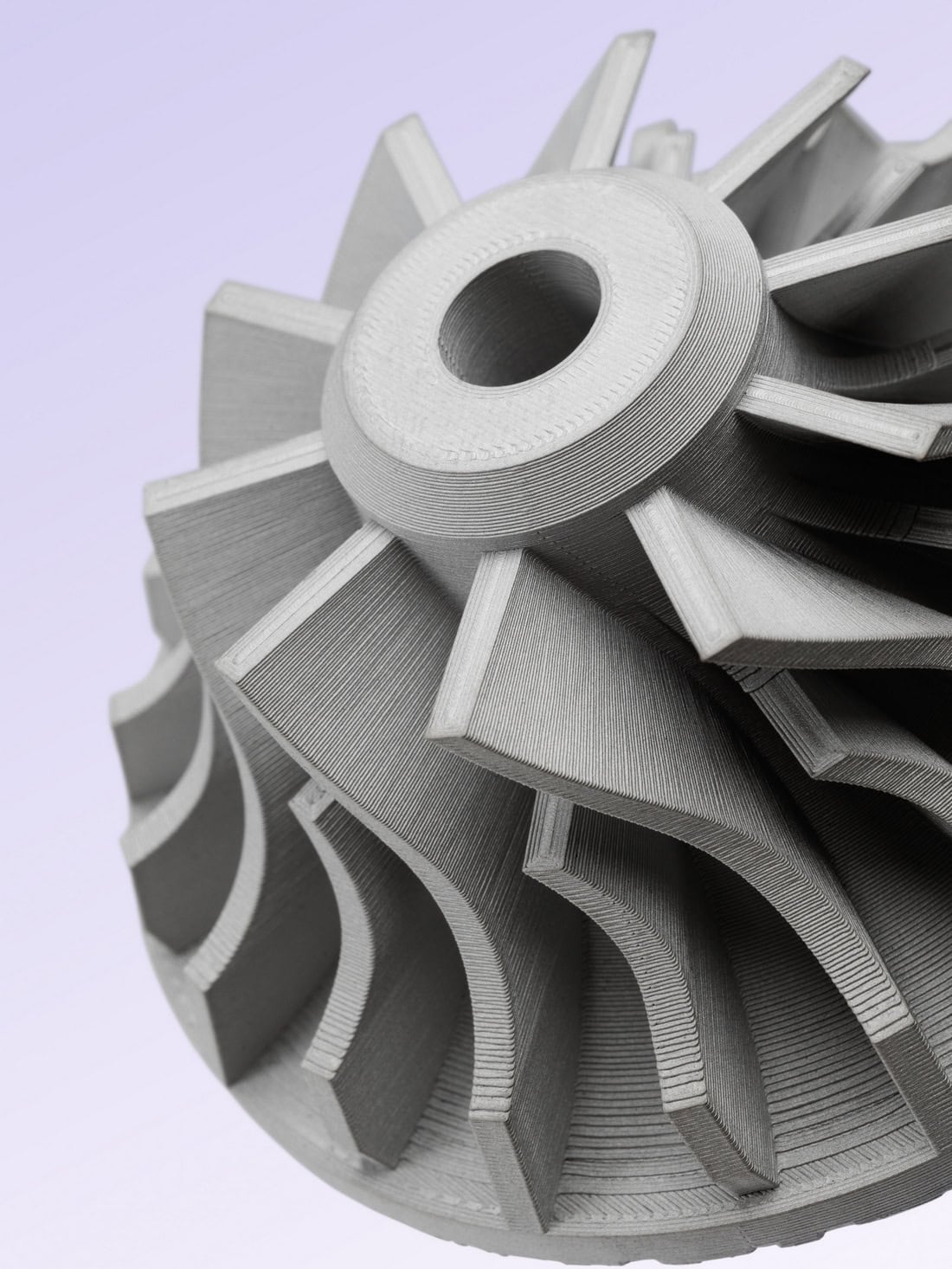

- blades and impellers

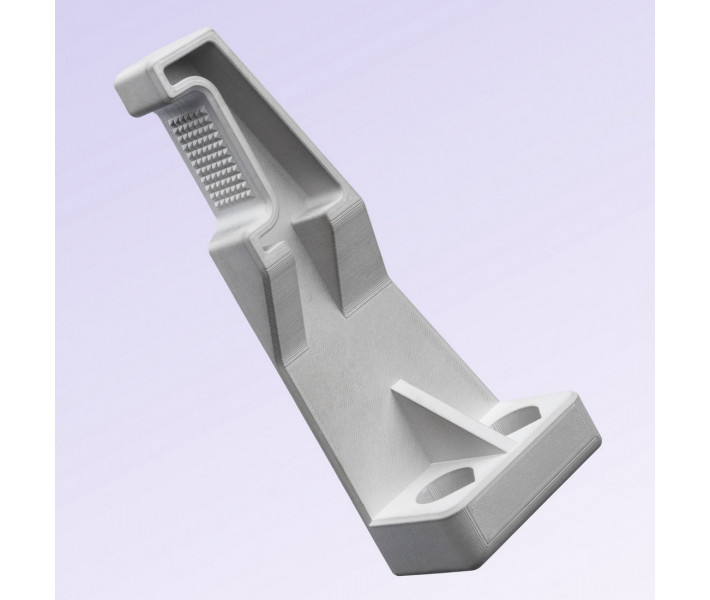

- lightweight brackets

- conveyor equipment

- tools and fixtures

- repair and maintenance components

- components for the oil and gas industry

- parts for marine and chemical systems

Technical properties

The 316L steel for FX10 has balanced characteristics that ensure its versatility:

- high corrosion resistance even in challenging environments

- good impact toughness

- retention of mechanical properties over a wide temperature range

This makes the material for industrial 3D printing an ideal choice for companies looking to reduce manufacturing costs while obtaining long-lasting parts.

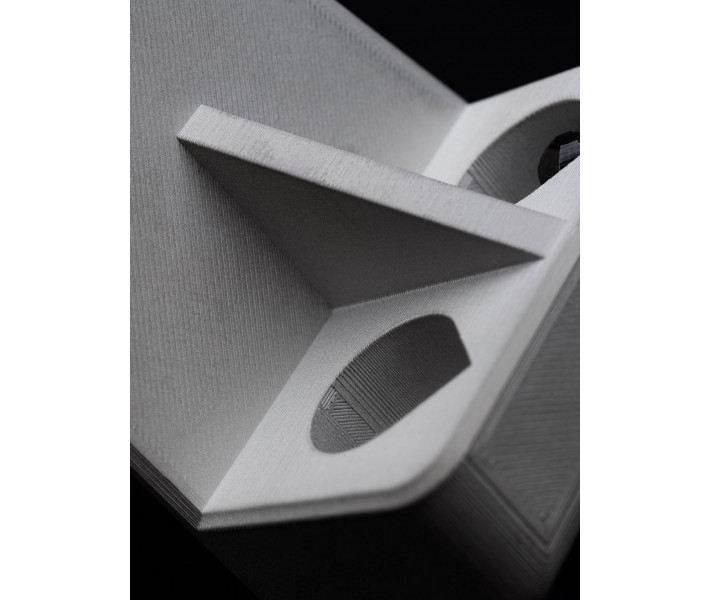

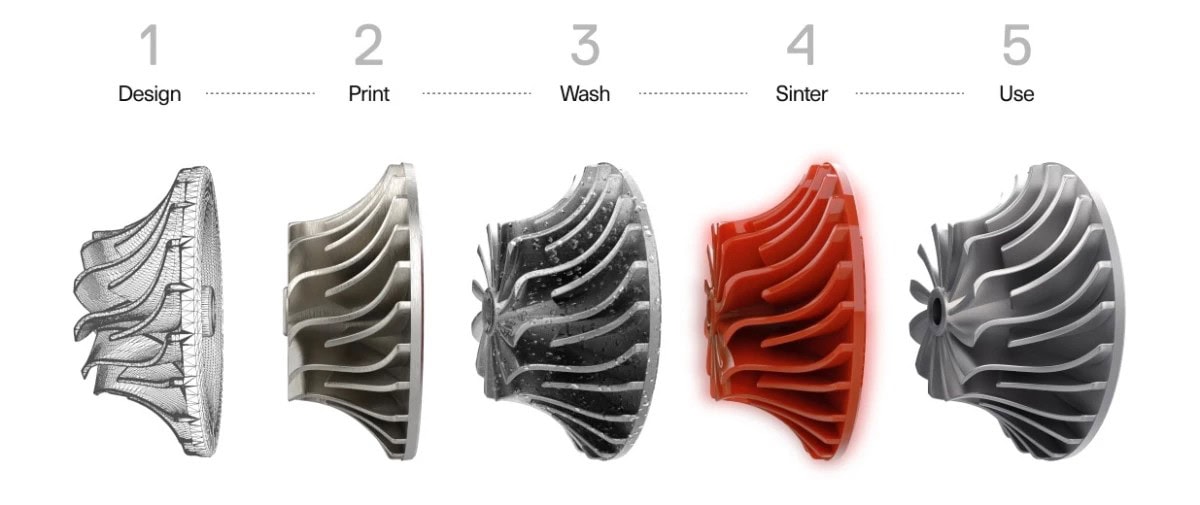

3D printing with stainless steel – a new level of production

Thanks to additive manufacturing technology, Markforged enables engineers to quickly create parts with complex geometries that are difficult or impossible to produce using traditional methods.

3D printing with stainless steel is a flexible and fast manufacturing method that paves the way for rapid prototyping and series production of functional components.

Compatibility

The metal filament is fully compatible with Markforged FX10 3D printers, which have the FX10 Metal Kit.

ADAM manufacturing technology

The 316L Stainless Steel material for the Markforged FX10 Metal Kit is produced in a filament format of 400 cm3, which contains 316L steel atoms bonded with a binder.

Buy Markforged metal filament in Ukraine

Purchase the metal 3D printing material Markforged 316L Stainless Steel at the 3DDevice store – we are the official representative of Markforged in Ukraine.

With over 10 years of experience in the field, we expertly provide consultations tailored to specific tasks and budgets. By choosing us, you receive a guarantee of original products, professional support, and confidence in the result.

3D Printers

- Metal X

- FX10

- FX20

- X7 (Gen 2)

- X7 (Gen 2) Field Edition

- X7 (Gen 2) Field Edition Brochure

- Mark Two (Gen 2)

- Onyx Pro (Gen 2)

Additional Equipment

Materials

Metal

Markforged Metal Filaments combine the simplicity and safety of FFF printing with the superior properties of advanced metals, bringing metal 3D printing to your benchtop.

- 17-4PH Stainless Steel

- 316L Stainless Steel

- Copper

- H13 Tool Steel

- Inconel 625

- A2 Tool Steel

- D2 Tool Steel

Plastics

Composite Base filaments are engineering-grade materials that print using a conventional FFF (FDM-style) process. Print with them alone or with Continuous Fibers to yield strong parts. The ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.

Continuous Fiber

Continuous Fibers enable Markforged composite printers to print metal-strength parts. They cannot be used alone — however, when printed with a Composite Base, they form the backbone of a strong printed part.