- Stock: In Stock

- Product code: 00-00013561

- Shipping Weight: 5.50kg

- SKU: RS-RPS-TO10-01

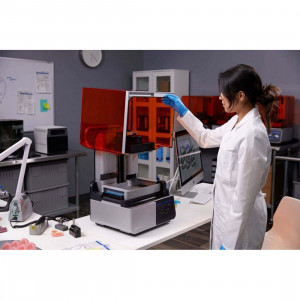

Unlock the potential of industrial-grade 3D printing with the Formlabs Tough 1000 Resin Form 4, 5L. Designed specifically for the high-speed Form 4 ecosystem, this material offers mechanical performance that rivals high-density polyethylene (HDPE). Whether you are prototyping functional assemblies or manufacturing end-use parts, this 5-liter container ensures you have the volume needed for continuous production, providing exceptional impact resistance and ductility for your most demanding engineering challenges. Please note that this large-format container requires a Resin Pump for operation.

Why Choose Formlabs Tough 1000 Resin?

Engineering Grade Performance

This material stands out as a ductile, impact-resistant solution that mimics the strength and stiffness of standard industrial plastics. With an elongation at break of 180%, the Formlabs Tough 1000 Resin Form 4, 5L surpasses HDPE, making it the perfect choice for components that must withstand bending, compression, or deformation without cracking. It represents a significant leap forward in material science, offering five times the fracture toughness and improved environmental stability compared to previous Durable Resin formulations.

Superior Durability and Fatigue Resistance

Engineers rely on this resin for parts that undergo repetitive stress. Capable of enduring over 100,000 cycles without failure, it is ideal for printing functional hinges, springs, and compliant mechanisms. The material boasts a work of fracture of 3,200 J/m², ensuring that your jigs, fixtures, and enclosures remain intact even under significant physical stress in rugged factory environments.

Low-Friction Surface Finish

Beyond mechanical strength, parts printed with this resin feature a professional, matte dark grey finish that is smooth to the touch. It offers low-friction properties comparable to Delrin (POM), allowing for the creation of wear-resistant assemblies where surfaces slide against one another. This makes it excellent for ball joints, gears, and moving mechanical assemblies that require longevity and minimal abrasion.

Key Applications for Tough 1000 Resin

Versatile Manufacturing Solutions

The unique properties of this photopolymer make it suitable for a wide range of engineering tasks. It is specifically engineered for parts requiring the stiffness of HDPE, impact-resistant tools that survive long-term shop floor use, and non-degrading surfaces. From prototyping snap-fits to creating robust end-use casings, this material delivers consistent, high-quality results.

Post-Processing Recommendations

Achieving Maximum Strength

To ensure your prints reach their full mechanical potential, proper post-processing is essential. After printing, parts should be washed in alcohol or ether to remove excess resin. Formlabs recommends air drying parts for at least 30 minutes after washing for the best surface finish. Finally, post-curing is critical to transition the part from a green state to a fully finished component with maximum strength and stability.

Mechanical Properties

- Ultimate Tensile Strength: 26.3 MPa

- Tensile Modulus: 932 MPa

- Elongation at Break: 180%

- Gardner Impact @ 1/32" (0.8 mm): 13.1 J

- Work of Fracture: 3200 J/m^2

- Heat Deflection Temp @ 0.45 MPa: 55.3 °C

Buy Formlabs Tough 1000 Resin Form 4, 5L at 3DDevice

When you choose to purchase from the 3DDevice online store, you are trusting experts with extensive experience in the additive manufacturing market since 2012. As an official representative of Formlabs, we guarantee the best prices, full official warranty, and certified service support for your equipment and materials. Our team provides professional advice to help you select the right solutions for your specific needs, ensuring qualified support before, during, and after your purchase.