- Stock: In Stock

- Product code: 00-00011361

- Shipping Weight: 1.50kg

- SKU: RS-C2-SI40-01

Formlabs Silicone 40A Resin for 3D Printing

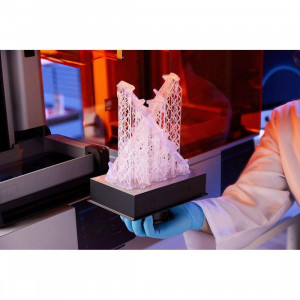

The resin Formlabs Silicone 40A Resin is the first available material for 3D printing made from 100% pure silicone, created with innovative Pure Silicone Technology™. It opens up new possibilities for manufacturing functional parts without the need for traditional casting or complex forming processes. This allows users to print silicone products right in their workshop, obtaining ready parts in just a few hours. This silicone resin for 3D printing is ideal for both prototyping and final production.

Main Material Properties

The resin has a Shore hardness of 40A and combines softness, flexibility, and durability. Products withstand multiple cycles of bending, stretching, and compression while maintaining their characteristics.

- Elongation at break – 230%

- Tensile strength – 5.5 MPa

- Tear resistance – 12 kN/m

- Operating temperature – from -25 °C to +125 °C

- Excellent chemical resistance

This elastic resin for prototypes allows creating parts that withstand challenging operating conditions.

Advantages of Use

- Manufacturing parts without tooling – reduces costs and shortens timelines.

- Ability to print complex geometries and thin elements from 0.3 mm.

- Stable isotropic properties and high surface quality.

- Compatibility with the Formlabs SLA ecosystem for fast and convenient production.

This solution is suitable for those planning to buy Formlabs Resin for engineering and medical tasks.

Outstanding Elastomeric Characteristics

Manufacture soft, flexible, and durable parts with an elongation at break of 230% and tear strength of 12 kN/m, which withstand multiple cycles of stretching, bending, and compression. Create highly functional silicone parts with excellent chemical resistance and thermal stability (from -25°C to +125°C).

Cost-effective Rapid Prototyping and Small Batch Production

Eliminate tooling and labor-intensive casting processes to ensure custom and small-scale production of silicone parts.

New Design Freedom

Create custom silicone parts with isotropic properties, thin elements from 0.3 mm, and complex geometry that cannot be reproduced through casting or molding.

Fast and Easy Manufacturing

Take advantage of the optimized Formlabs SLA ecosystem for producing pure silicone parts on your own in just a few hours.

![]()

Applications

Formlabs Silicone 40A Resin is widely used in various industries:

- Automotive and Robotics Industry – seals, gaskets, dampers, connectors.

- Consumer Goods – handles, pads, flexible elements, wearable devices.

- Medicine – prosthetics, orthopedic products, hearing aids, medical models. As a material for medical models, the resin has proven to be a reliable solution.

- Manufacturing – soft tools, flexible fixtures, casting molds for polyurethane or resins.

This is a versatile solution for engineers, designers, and medical professionals who need resin for industrial 3D printing.

Equipment Compatibility

- The resin is specifically designed for Formlabs 3D printers Form 4 and Form 4B.

- Compatible with Form 4 Resin Tank.

- Platforms Form 4 Build Platform and Form 4 Flex Build Platform.

- The material has certified biocompatibility, allowing its use in healthcare.

Buy Silicone for 3D Printing in Ukraine

The Formlabs Silicone 40A Resin is an innovative material for 3D printing that combines all the advantages of pure silicone and SLA technology. It provides rapid production of elastic, durable, and functional parts for a wide range of applications.

Buy Silicone 40A Resin in Ukraine at 3DDevice. We are an official authorized Formlabs distributor in Ukraine, ensuring genuine products and professional support.