- Stock: In Stock

- Product code: 00-00000263

- Shipping Weight: 1.50kg

- SKU: RS-F2-SI40-01

100% pure silicone for 3D printing

Silicone 40A Resin – silicone for Formlabs 3D printers – is the first affordable 100% silicone material for photopolymer 3D printing.

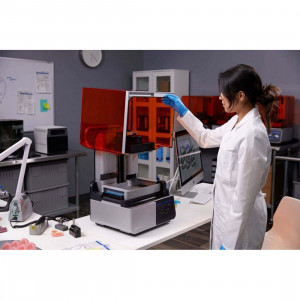

This new addition to the Formlabs engineering resin library is revolutionizing silicone manufacturing: you no longer need the labor-intensive and costly processes of traditional molding and casting. Formlabs offers a new patented technology for photopolymerization of silicone. Use the advanced Formlabs Form 3+ ecosystem to photopolymerize 100% silicone parts in your own office in a matter of hours.

With this Shore 40A hardness material, you can create soft, flexible, and durable parts with 250% elongation at break and 12 kN/m tensile strength that can withstand repeated cycles of stretching, bending, and compression. They can combine the high performance of silicone with the design freedom of 3D printing to create highly functional silicone parts with excellent chemical and thermal resistance (from -25°C to 125°C), fine details as small as 0.3 mm, and complex geometries that are impossible with traditional methods. Thanks to Formlabs, cost-effective rapid prototyping and short-run production of silicone parts are now available to you.

3D printing with pure silicone – advantages

Silicone 40A Resin is pure silicone with no added monomer or acrylate, created using Formlabs' new patented Pure Silicone Technology™. Silicone 40A Resin combines the excellent properties of cast silicone with the advantages of 3D printing.

Outstanding elastomeric characteristics

The material prints highly functional silicone parts that are soft, flexible, and durable, with excellent chemical resistance and thermal stability.

Cost-effective rapid prototyping and low-volume production

Expensive tools and labor-intensive casting processes are necessary. Print custom and low-volume silicone products on a 3D printer right in your home, factory, lab, workshop, or office.

New design freedom

Create custom silicone parts with isotropic properties, thin features as small as 0.3 mm, and complex geometries that are impossible to achieve with casting or molding.

Fast and easy manufacturing

Take advantage of Formlabs' optimized SLA ecosystem to produce clean silicone parts in-house in a matter of hours.

![]()

Properties of Silicone 40A

Below are the characteristics of a sample printed with Silicone 40A resin and polymerized at 60 ºC for 30 minutes:

- Shore hardness – 40A

- Tensile strength – 5.5 MPa

- Elongation at break – 230%

- Tensile strength – 12 kN/m

- Rebound resistance – 34%

- Glass transition temperature (Tg) – -110 °C

- Ross Flexing Fatigue (-10 °C, serrated) – > 500,000 cycles

- Ross Flexing Fatigue (23 °C, serrated) – > 500,000 cycles

- Cytotoxicity – Pending (undergoing testing and certification)

![]()

Applications

Silicone 40A Resin is a cost-effective solution for manufacturing functional prototypes, test blocks, tools, and small batches of silicone parts.

Parts printed with Silicone 40A resin are used in industries such as consumer goods, automotive, robotics, manufacturing, and healthcare.

Recommended for 3D printing:

- Seals, gaskets, actuators, and connectors

- Wearable and flexible consumer goods

- Flexible lighting and masking masters

- Keyboards, buttons, and human-machine interaction devices

Not recommended for:

- Unsupported thin-walled geometries thinner than 0.7 mm

- Prolonged exposure to UV light

Disclaimer: Formlabs is currently awaiting TSCA registration. Until then, Silicone 40A Resin can only be used for research and development (R&D) purposes. TSCA registration is expected in late 2023. Once registered, this resin can be used for commercial purposes, research and development, and any other appropriate applications.