- Stock: In Stock

- Product code: 00-00013547

- Shipping Weight: 1.50kg

- SKU: RS-F2-PTA2-01

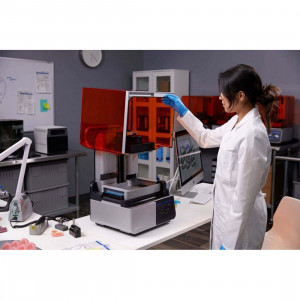

Elevate your restorative capabilities with Formlabs Premium Teeth HT A2 Resin Form 3 Cartridge, 1kg 0.8L. This advanced, nano-ceramic filled biocompatible material is engineered to deliver the highest level of aesthetics and mechanical performance for dental appliances. Designed for use with the Form 3 ecosystem, it allows dental professionals to 3D print lifelike denture teeth, temporary implant-supported restorations, and robust bridges that rival traditional methods in both look and longevity.

Redefining Digital Restorations with Nano-Ceramic Technology

Unmatched Mechanical Integrity

Experience industry-leading durability. Premium Teeth Resin is fortified with nano-ceramic fillers, providing exceptional intraoral flexural strength while maintaining the necessary fracture toughness. This balance ensures that appliances can withstand the forces of mastication without failure, offering best-in-class mechanical properties for demanding dental applications.

Lifelike A2 Aesthetics

Create appliances that blend seamlessly with natural dentition. The resin offers optimized translucency, opalescence, and accurate A2 shading to produce realistic restorations. Whether for a single crown or a full denture, the final print delivers a natural appearance that satisfies high patient expectations.

Proven Longevity and Wear Resistance

Rely on a material rigorously tested for the oral environment. Premium Teeth Resin is formulated to resist abrasion, staining, and wear over time. Its validated longevity ensures that temporary restorations and denture teeth maintain their original characteristics and structural integrity throughout their use.

Streamlined Lab Workflow

Maximize laboratory efficiency with a material designed for ease of use. This resin simplifies the post-processing phase, offering easy polishability and full compatibility with conventional finishing tools. Achieve high-quality, accurate prints with reduced labor time.

Versatile Clinical Applications

Formlabs Premium Teeth Resin is the premier choice for a wide range of removable and fixed restorations, including:

- Denture teeth for removable prosthetics

- Temporary full-arch implant-supported restorations (All-on-X)

- Try-in dentures for fit verification

- Temporary single units (crowns, veneers, inlays, onlays)

- Temporary bridges (up to 7 units)

Digital Denture Workflow Guide

Follow this validated process to produce high-quality full dentures using Formlabs 3D printers.

Step 1: Design and Preparation

Begin by importing digital impressions into your dental CAD software. Design the denture base and teeth separately or as a monolithic unit depending on your preference. Ensure the design settings are optimized for the specific resin parameters. Export the files as STLs.

Step 2: Printing

Import the STL files into PreForm. Select "Premium Teeth Resin" for the teeth and a compatible Denture Base Resin for the base. Orient the teeth with the occlusal surface facing away from the build platform (angled 10-30 degrees) to preserve detail. Use a 50-micron layer height for the best balance of speed and surface quality. Print the parts on your Form 3 or Form 3B printer.

Step 3: Post-Processing

Wash the printed parts in isopropyl alcohol (IPA, ≥99%) using a Form Wash. Follow the recommended wash times strictly to avoid affecting the fit. Allow parts to air dry completely. Post-cure the teeth and base in a Form Cure according to the material's specific temperature and time requirements to achieve full biocompatibility and strength.

Step 4: Assembly and Bonding

Remove support structures and smooth the contact areas. If printing separately, bond the teeth to the denture base using uncured denture base resin. Cure the assembled denture again to ensure a seamless, strong bond between the teeth and the base.

Step 5: Finishing and Polishing

Polish the final appliance using standard dental polishing methods (pumice and high-shine compounds) to achieve a smooth, glass-like finish that mimics natural enamel and ensures patient comfort.

Material Properties

- Application: Dental

- Printing Technology: SLA

- Flexural Strength: 155 MPa

- Flexural Modulus: 4300 MPa

- Shore Hardness: 90D

- Opacity at 1mm thickness: 56%

Your Official Formlabs Partner

As an official representative of Formlabs, 3DDevice guarantees the best price, an official warranty, and professional service support. Our experts, with experience since 2012, are here to provide advice and assist you in making the right choice. Rely on us for qualified support before, during, and after your purchase to ensure you achieve the best possible results with your 3D printing projects.