- Stock: In Stock

- Product code: 00-00000302

- Shipping Weight: 5.50kg

- SKU: PD-FS-PLPG-01

Buy Polypropylene Powder SLS for Formlabs Fuse

On this page, you can buy Polypropylene Powder for Formlabs Fuse 1+30W 3D printer. Use real polypropylene to make working prototypes and durable end-use parts that are chemically resistant, weldable, and waterproof. Formlabs Polypropylene Powder offers high ductility, allowing for repeated bending and flexing while providing durability, without the need for inert atmospheric control.

This material requires a Sift 300 sieve for use with Fuse Sift.

Polypropylene for SLS 3D printing features

- Ultimate Tensile Strength – 29.0 MPa.

- Flexural Strength – 37.0 MPa.

- Tensile Modulus – 1.64 GPa.

- Impact resistant and waterproof material with very low moisture absorption.

- Chemically resistant – withstands a wide range of acids, alkalis, organic solvents, fuels and alcohols.

Advantages of Formlabs Polypropylene Powder

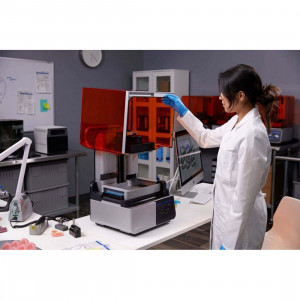

Use the Fuse 1+ 30W printer to 3D print Polypropylene Powder right in your office or small workshop. The process is quick and easy, and the resulting parts will be strong, malleable, and water resistant.

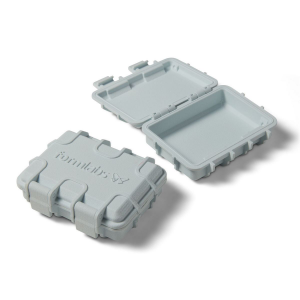

- Real polypropylene. Helps bring products to market quickly and cost-effectively. Print functional prototypes or small runs of parts before mass production. This allows you to test the design and make sure it meets your requirements before mass producing in the traditional way.

- Lightweight, high ductility. 3D printed polypropylene offers high strength and durability. It is also lightweight and resistant to damage. This polypropylene is used to print lightweight parts that have the mechanical properties of conventional injection molded polypropylene. These properties make it ideal for prototyping and production of end products operating in demanding environments.

- Excellent chemical resistance. Create durable, waterproof, and chemical-resistant polypropylene parts on your SLS 3D printer. Parts made from this material have very low moisture absorption, which means they won’t warp or degrade when exposed to water. They are also resistant to a wide range of acids, alkalis, organic solvents, fuels and alcohols.

- Easy to use. Produce plastic parts with precise dimensions without inert atmospheric control.

SLS 3D printing from Polypropylene

Polypropylen Powder printed parts have the properties of real polypropylene for working prototypes and high-performance, lightweight and plastic end-use parts.

Polypropylene Powder doesn’t require nor benefit from inert atmospheric control. It can therefore be printed in air with optimal results.

- Packaging prototypes, waterproof enclosures, cases.

- Automotive interior components.

- 3D printing for medicine – orthotics and prosthetics.

- Durable and chemical resistant fixtures, tools and devices.

- Waterproof elements that must contain or transfer liquids without additional processing steps – vessels, fittings, tubes.

* Material properties may vary depending on part design and manufacturing methods. The manufacturer is responsible for verifying that the printed parts are suitable for their intended use.

Compatibility with Formlabs Fuse equipment

- Printer compatibility: Fuse 1+ 30W

- Material requires a Sift 300 sieve for use with Fuse Sift.

Downloads:

Technical Data Sheet, PDF (EN)

Authorized Partner of Formlabs in Ukraine and Moldova

3DDevice is an authorized partner of Formlabs in Ukraine and Moldova.

Here you can buy SLS 3D Formlabs printers, components and raw materials for them with the official manufacturer’s warranty. When you buy Formlabs equipment in 3DDevice you get training, equipment installation and service. For consultations, contact us.

Buy in Ukraine Polypropylene for SLS 3D printing

Fuse 1 | Fuse 1+ 30W | |

Nylon 11 | ✔ | ✔ |

Nylon 11 CF | ✔ | |

Nylon 12 | ✔ | ✔ |

Nylon 12 White | ✔ | |

Nylon 12 Tough | ✔ | |

Nylon 12 GF | ✔ | ✔ |

TPU 90A | ✔ | ✔ |

Polypropylene | ✔ |