- Stock: In Stock

- Product code: 00-00000298

- Shipping Weight: 6.50kg

- SKU: PD-FS-P12B-01

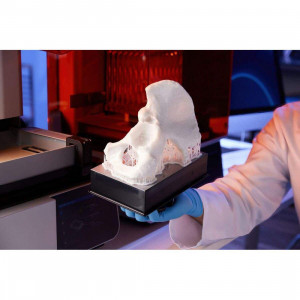

Nylon 12 GF Glass-Filled Powder for SLS Printing

Glass-filled Nylon Nylon 12 GF is a new material for Formlabs 3D printers Fuse 1 and Fuse 1+ 30W.

This glass-filled material is characterized by increased structural rigidity, thermal stability, and insensitivity to environmental influences. It hardly absorbs moisture, is resistant to sunlight and various chemicals. The addition of glass makes Nylon 12 GF stable and not prone to deformation.

- Tensile modulus – 2800 MPa

- Heat deflection temperature at 1.8 MPa – 113 °C

- Material refresh rate – 30 – 50%

Applications of Nylon 12 GF

Thanks to its properties, the material is used for printing functional prototypes and durable end-use products where dimensional accuracy is important, and which will operate in conditions where resistance to moisture, various solvents, and wide temperature fluctuations is crucial:

- Fastening devices resistant to prolonged load;

- Functional prototypes for composite products;

- Rigid structural components;

- Device and instrument housings resistant to thermal effects;

- End-use industrial models.

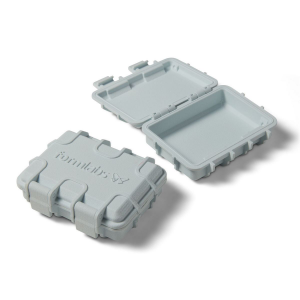

Nylon 12 GF powder is supplied in a box containing two 3 kg containers and an RFID card with a pre-loaded virtual credit for printing.

Fresh powder is added to Formlabs Fuse Sift, and the “powder credit” is loaded into Fuse 1 to track material usage and available unsintered powder.

Properties of Nylon 12 GF Material

- High rigidity

- Thermal resistance

- Dimensional accuracy

- Environmental stability

| Values in Metric System1,2 | Method: | |

| Tensile Properties: | ||

| Tensile strength | 38 MPa | ASTM D638-14 Type 1 |

| Tensile modulus | 2800 MPa | ASTM D638-14 Type 1 |

| Elongation at break (X/Y) | 4% | ASTM D638-14 Type 1 |

| Elongation at break (Z) | 3% | ASTM D638-14 Type 1 |

| Elastic Properties: | ||

| Flexural strength | 56 MPa | ASTM D790-15 |

| Flexural modulus | 2400 MPa | ASTM D79015 |

| Mechanical Properties: | ||

| Izod impact strength with notch | 36 J/m | ASTM D256-10 |

| Thermal Properties: | ||

| Heat deflection temperature at 1.8 MPa | 113 ⁰C | ASTM D648-16 |

| Heat deflection temperature at 0.45 MPa | 170 ⁰C | ASTM D648-16 |

| Vicat softening temperature | 175 ⁰C | ASTM D1525 |

| Other Properties: | ||

| Moisture content (powder) | 0.23% | ISO 15512 Method D |

| Water absorption (printed model) | 0.24% | ASTM D570 |

1 Material properties may vary depending on the geometric shape of the part, printing settings, and temperature.

2 Models were printed on a Fuse 1 printer from Nylon 12 GF powder. Before testing, models were stored at 50% relative humidity and 23 °C for 7 days.

Glass-Filled Nylon: Solvent Compatibility

Percentage weight increase over 24 hours for a printed cube measuring 1x1x1 cm, immersed in the respective solvent:

| Solvent | Weight Increase After 24 Hours (%) | Solvent | Weight Increase After 24 Hours (%) |

| 5% Acetic Acid | 0.2 | Heavy Mineral Oil | 1.0 |

| Acetone | 0.2 | Light Mineral Oil | 1.3 |

| Bleach ~ 5% NaOCl | 0.2 | Saltwater (3.5% NaCl) | 0.2 |

| Butyl Acetate | 0.2 | Skydrol 5 | 0.8 |

| Diesel Fuel | 0.6 | Sodium Hydroxide Solution (0.025% pH = 10) | 0.2 |

| Diethylene Glycol Monomethyl Ether | 0.5 | Strong Acid (conc. HCl) | 0.8 |

| Hydraulic Oil | 1.0 | TPM | 0.8 |

| Hydrogen Peroxide (3%) | 0.2 | Water | 0.1 |

| Isooctane | 0.0 | Xylene | 0.2 |

| Isopropyl Alcohol | 0.2 |

All questions regarding this product can be addressed to our specialists.

Download Files:

Technical Data Sheet, PDF (EN)

Buy Glass-Filled Nylon Nylon 12 GF in Ukraine

Fuse 1 | Fuse 1+ 30W | |

Nylon 11 | ✔ | ✔ |

Nylon 11 CF | ✔ | |

Nylon 12 | ✔ | ✔ |

Nylon 12 White | ✔ | |

Nylon 12 Tough | ✔ | |

Nylon 12 GF | ✔ | ✔ |

TPU 90A | ✔ | ✔ |

Polypropylene | ✔ |