- Stock: In Stock

- Product code: 00-00000299

- Shipping Weight: 6.50kg

- SKU: PD-FS-P11B-01

Nylon 11 Powder 6 kg for 3D Printing SLS on Formlabs Fuse 1

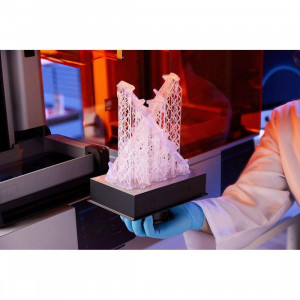

Nylon 11 Powder is a special material in powder form for 3D printing on a Formlabs Fuse 1 3D printer. Packaged in 2 airtight bottles of 3 kg each.

This is a high-performance bio-based nylon for SLS technology to produce plastic and durable functional parts. It is used in functional prototyping and small batch production.

SLS Nylon-11 Powder Parts Have

- High tensile strength.

- Flexibility and environmental resistance.

- Minimal water absorption.

Due to the laser sintering of Nylon 11 Powder layers in the Build Chamber of the Fuse 1 3D printer, the printed part is built up in the powder volume, creating a solid product. From it, you can create functional parts with a high degree of detail and complex configurations.

Parts made from Nylon 11 withstand wear over time. For more effective functional prototypes and end-use products. Nylon 11 Powder parts can withstand various impacts and continue to function.

Nylon 11 for 3D Printing is Ideal for:

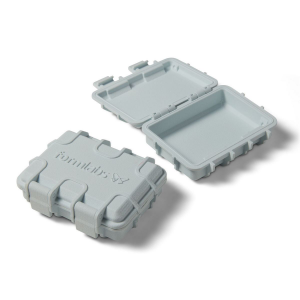

- Impact-resistant prototypes, tools, and fixtures

- Buttons, clips, and hinges

- Thin-walled ducts and enclosures

- Orthopedics and prosthetics.

Formlabs SLS 3D printing powder is supplied in a box containing two 3 kg containers and an RFID card with preloaded virtual print credit.

Fresh powder is added to the Formlabs Fuse Sift, and the "powder credit" is added to the Fuse 1 to track material usage and available unsintered powder.

Tensile Strength of Nylon 11 and Nylon 12

Material Properties of Nylon 11

| Metric Values1,2 | Method: | |

| Tensile Properties: | ||

| Tensile Strength | 49 MPa | ASTM D638 Type 1 |

| Tensile Modulus | 1.6 GPa | ASTM D638 Type 1 |

| Elongation at Break (X/Y) | 40% | ASTM D638 Type 1 |

| Flexural Properties: | ||

| Flexural Strength | 55 MPa | ASTM D790 A |

| Flexural Modulus | 1.4 GPa | ASTM D790 A |

| Impact Properties: | ||

| Izod Impact Strength, Notched | 71 J/m | ASTM D256 |

| Thermal Properties: | ||

| Heat Deflection Temperature at 1.8 MPa | 46 ⁰C | ASTM D648 |

| Heat Deflection Temperature at 0.45 MPa | 182 ⁰C | ASTM D648 |

| Vicat Softening Temperature | 189 ⁰C | ASTM D1525 |

| Other Properties: | ||

| Moisture Content (Powder) | 0.37% | ISO 15512 Method D |

| Water Absorption (Printed Part) | 0.37% | ASTM D570 |

Nylon 11 for Fuse 1 Meets Biocompatibility Risk Requirements

Nylon 11 Powder has been evaluated as a skin contact material according to ISO 10993-1 and has been tested for compliance with the following biocompatibility endpoints:

| ISO Standard | Test Result3,4 |

| ISO 10993-5 | Non-cytotoxic |

| ISO 10993-10 | Non-irritating |

Solvent Compatibility of Nylon 11

Percentage weight increase over 24 hours for a printed cube measuring 1x1x1 cm, immersed in the corresponding solvent:

| Solvent | Weight Increase Over 24 Hours (%) |

| Acetic Acid 5% | 0.1 |

| Acetone | 0.1 |

| Bleach ~ 5% NaOCl | 0.1 |

| Butyl Acetate | 0.1 |

| Diesel Fuel | 0.2 |

| Monomethyl Ether of Diethylene Glycol | 0.4 |

| Hydraulic Oil | 0.5 |

| Hydrogen Peroxide (3%) | < 0.1 |

| Isooctane | < 0.1 |

| Isopropyl Alcohol | 0.1 |

| Mineral Oil Heavy | 0.4 |

| Mineral Oil Light | 0.4 |

| Salt Water (3.5% NaCl) | 0.1 |

| Skydrol 5 | 0.3 |

| Sodium Hydroxide Solution (0.025% pH = 10) | 0.1 |

| Strong Acid (Conc. HCl) | 1.0 |

| TPM | 0.3 |

| Water | 0.1 |

| Xylene | 0.1 |

1 Material properties may vary depending on part geometry, print orientation, and temperature.

2 Parts were printed on a Fuse 1 3D printer with Nylon 11. Before testing, parts were conditioned at 50% relative humidity and 23 °C for 7 days.

3 Material properties may vary depending on part design and manufacturing practices. The manufacturer is responsible for verifying the suitability of printed parts for the intended use.

4 Nylon 11 was tested at the NAMSA headquarters, Ohio, USA.

Printing with Nylon 11 on the New Formlabs Fuse 1+ 30W Printer

Printing on the new Formlabs Fuse 1+ 30W printer can be done with 70% recycled powder:

All questions regarding this product can be addressed to our specialists.

Download Files:

Fuse 1 | Fuse 1+ 30W | |

Nylon 11 | ✔ | ✔ |

Nylon 11 CF | ✔ | |

Nylon 12 | ✔ | ✔ |

Nylon 12 White | ✔ | |

Nylon 12 Tough | ✔ | |

Nylon 12 GF | ✔ | ✔ |

TPU 90A | ✔ | ✔ |

Polypropylene | ✔ |