- Stock: In Stock

- Product code: 00-00000300

- Shipping Weight: 6.50kg

- SKU: PD-FS-P11C-01

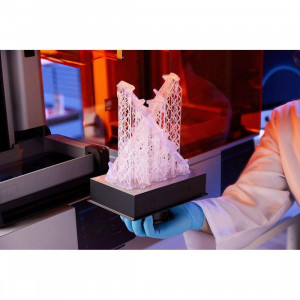

Reinforced Nylon 11 CF with Carbon Fiber for SLS Printing

Nylon with carbon fiber Nylon 11 CF is a new material from Formlabs, supplied with the 3D printer Fuse 1+ 30W.

This is an engineering material based on Nylon 11, to which chopped carbon fiber has been added, allowing users to print rigid, strong, and lightweight parts directly in their workshop.

- Tensile strength (X) – 69 MPa

- Tensile modulus (X) – up to 5300 MPa

- Material refresh rate – 30%

Applications of Nylon 11 CF

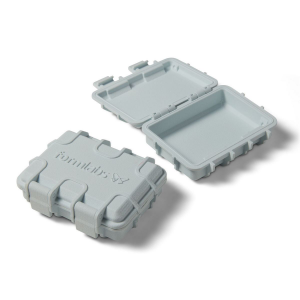

Use Nylon 11 CF for printing finished parts and prototypes that require high rigidity, excellent strength, and lightness:

- Functional composite prototypes.

- Tooling, clamping, and fastening devices.

- Spare parts and metal part replacements.

- Impact-resistant equipment.

Note that Nylon 11 CF powder requires a sieve with a cell size of 300 microns Sift 300 Sieve.

Material Properties of Nylon 11 CF

| Values in Metric System1,2 | Method: | |||

| Tensile Properties: | X | Y | Z | |

| Tensile strength | 69 MPa | 52 MPa | 38 MPa | ASTM D638-14 Type 1 |

| Tensile modulus | 5.3 GPa | 2.8 GPa | 1.6 GPa | ASTM D638-14 Type 1 |

| Elongation at break | 9% | 15% | 5% | ASTM D638-14 Type 1 |

| Mechanical Properties: | ||||

| Flexural strength | 110 MPa | ASTM D790-15 | ||

| Flexural modulus | 4.2 GPa | ASTM D790-15 | ||

| Izod impact strength with notch | 74 J/m | ASTM D256-10 | ||

| Thermal Properties: | ||||

| Heat deflection temperature at 1.8 MPa | 178 ⁰C | ASTM D648-16 | ||

| Heat deflection temperature at 0.45 MPa | 188 ⁰C | ASTM D648-16 | ||

| Vicat softening temperature | 188 ⁰C | ASTM D1525 | ||

1 Material properties may vary depending on the geometric shape of the part, printing settings, and temperature.

2 Models were printed on the Fuse 1 printer from Nylon 11 CF powder. Before testing, models were stored at 50% relative humidity and a temperature of 23°C for 7 days.

Compatibility of Nylon 11 CF with Solvents

Percentage weight increase over 24 hours for a printed cube measuring 1x1x1 cm, immersed in the corresponding solvent:

| Solvent | Weight increase after 24 hours (%) | Solvent | Weight increase after 24 hours (%) |

| Acetic acid 5% | 0.2 | Heavy mineral oil | 1.0 |

| Acetone | 0.2 | Light mineral oil | 1.3 |

| Bleach ~ 5% NaOCl | 0.2 | Saltwater (3.5% NaCl) | 0.2 |

| Butyl acetate | 0.2 | Skydrol 5 | 0.8 |

| Diesel fuel | 0.6 | Sodium hydroxide solution (0.025% pH = 10) | 0.2 |

| Monomethyl ether of diethylene glycol | 0.5 | Strong acid (HCl conc.) | 0.8 |

| Hydraulic oil | 1.0 | TRM | 0.8 |

| Hydrogen peroxide (3%) | 0.2 | Water | 0.1 |

| Isooctane | 0.0 | Xylene | 0.2 |

| Isopropyl alcohol | 0.2 |

All questions regarding this product can be addressed to our specialists.

Download files:

Technical Data Sheet, PDF (EN)

Buy reinforced with carbon fiber Nylon 11 CF in Kyiv

Fuse 1 | Fuse 1+ 30W | |

Nylon 11 | ✔ | ✔ |

Nylon 11 CF | ✔ | |

Nylon 12 | ✔ | ✔ |

Nylon 12 White | ✔ | |

Nylon 12 Tough | ✔ | |

Nylon 12 GF | ✔ | ✔ |

TPU 90A | ✔ | ✔ |

Polypropylene | ✔ |