- Stock: In Stock

- Product code: 00-00013578

- Shipping Weight: 5.50kg

- SKU: RS-RPS-HTAM-02

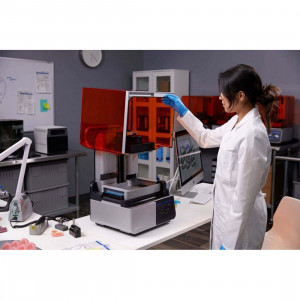

Unlock the potential of advanced manufacturing with the Formlabs High Temp Resin, 5L, a material engineered for professionals who demand exceptional thermal performance. This large-volume container is designed for high-throughput production and requires a Resin Pump for operation, ensuring a seamless workflow for your industrial 3D printing needs. As the material with the highest heat deflection temperature in the manufacturer's portfolio, it is the ultimate solution for creating precise prototypes and end-use parts that must withstand extreme heat without deforming. Whether you are developing complex machinery or testing environmental resistance, this resin delivers reliability and precision.

Unmatched Thermal Stability of Formlabs High Temp Resin

Defying Extreme Heat

The defining characteristic of this photopolymer is its incredible resistance to temperature. With a Heat Deflection Temperature (HDT) of 238 °C @ 0.45 MPa, Formlabs High Temp Resin, 5L outperforms all other standard resins in this class. This makes it an indispensable tool for engineers and designers who need to simulate the thermal properties of high-performance thermoplastics. By choosing this material, you ensure that your components maintain their dimensional accuracy and structural integrity even when exposed to intense heat sources.

Rigid and Precise

Beyond its thermal capabilities, this resin offers high stiffness and excellent surface finish. It is specifically formulated to produce parts with fine details and sharp edges, making it suitable for intricate designs. However, users should note that the material has very low flexibility. It is not suitable for snap-fits or living hinges but excels in static applications where rigidity is paramount. The 5L container allows for continuous printing of large batches, maximizing the efficiency of your Formlabs ecosystem.

Key Applications in Engineering and Manufacturing

Versatile Industrial Uses

The unique properties of Formlabs High Temp Resin open up a wide range of application possibilities. It is widely used for creating heat-resistant mounts, housings, and fixtures that operate in hot environments. Additionally, it is the ideal choice for prototyping parts that will be subjected to the flow of hot air, gas, or fluids. Its ability to withstand high temperatures also makes it perfect for vulcanization processes and electronics encapsulation.

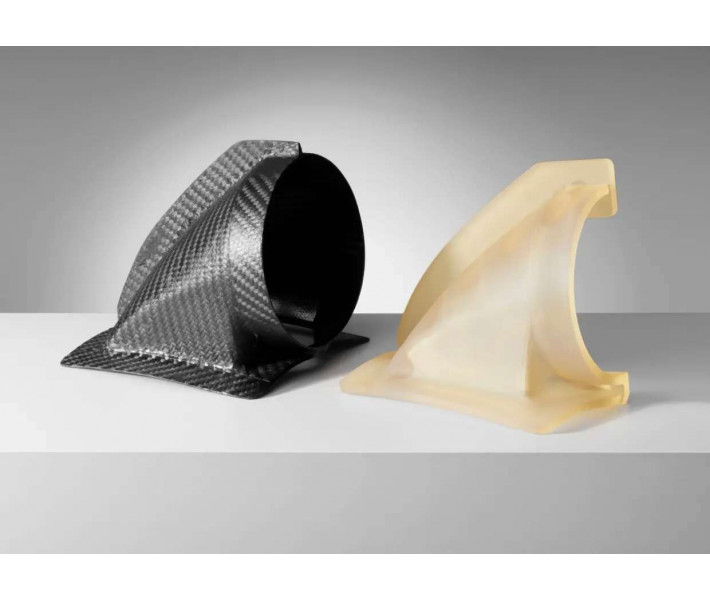

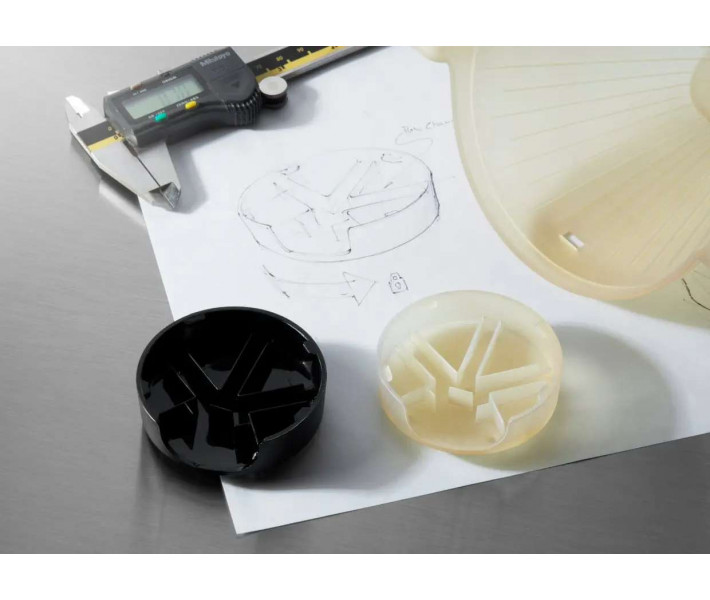

Molding and Tooling

One of the most powerful applications for this material is in the creation of rapid tooling. It is excellent for printing molds and inserts used in low-volume injection molding or thermoforming. This allows manufacturers to bridge the gap between prototyping and mass production, testing designs with real production materials without the high cost of metal tooling. The resin's stability ensures that the molds retain their shape under the heat and pressure of the molding process.

Workflow and Post-Processing Recommendations

Printing Best Practices

To achieve optimal results with Formlabs High Temp Resin, 5L, it is essential to follow specific printing guidelines. The material supports layer heights of 25, 50, and 100 microns, allowing you to balance speed and resolution. Due to its rigidity, parts should always be printed with supports to prevent adhesion issues with the build platform. Furthermore, using a standard resin tank requires regular inspection of the elastic layer, as this high-performance material can shorten tank lifespan.

Essential Curing Steps

Post-processing is critical to unlocking the full mechanical properties of this resin. After printing, parts must be washed in isopropyl alcohol (IPA) to remove uncured material, but soak times should be limited to 6 minutes to prevent solvent absorption. Following the wash, a thorough thermal post-cure is mandatory. This step completes the polymerization process, ensuring the part achieves its maximum strength and heat deflection temperature, making it ready for real-world application.

Technical Specifications

- Product Name: Formlabs High Temp Resin, 5L

- Container Volume: 5 Liters (Requires Resin Pump)

- Heat Deflection Temperature (HDT): 238 °C @ 0.45 MPa (V2), 289 °C @ 0.45 MPa (V1)

- Technology: SLA (Stereolithography)

- Material Type: Translucent Engineering Resin

- Ultimate Tensile Strength (Post-Cured): 58 MPa

- Tensile Modulus (Post-Cured): 2.8 GPa

- Elongation at Break (Post-Cured): 3.3%

- Flexural Modulus (Post-Cured): 2.6 GPa

- Compatible Printers: Form 1+, Form 2, Form 3/3+, Form 3B/3B+, Form 3L/3BL, Form 4/4B, Form 4L/4BL

- Compatible Resin Tanks: Form 2 Standard, Form 2 LT, Form 3 Tank (all), Form 3L Tank (all), Form 4 Tank, Form 4L Tank

- Layer Thickness: 25, 50, 100 microns (depending on printer model)

- Shelf Life: Recommended 24 months

- Recommended Applications: Hot air/fluid flow components, molds, inserts, heat-resistant fixtures, vulcanization.

Make the right choice for your production needs by purchasing from 3DDevice. We are experts in additive manufacturing with experience dating back to 2012. Our team provides professional advice and assistance in choosing the right materials for your specific tasks. We offer qualified support before, during, and after your purchase to ensure your success. As an official representative of Formlabs, we guarantee the best prices, official warranty coverage, and certified service support for all your equipment and consumables.