- Stock: In Stock

- Product code: 00-00013577

- Shipping Weight: 5.50kg

- SKU: RS-RPS-FL80-11

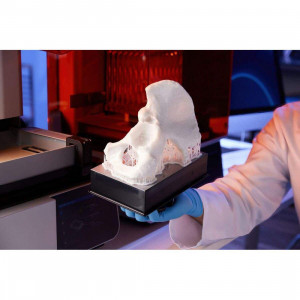

Scaling up your additive manufacturing workflow requires materials that deliver consistency and volume. The Formlabs Flexible 80A Resin Form 4, 5L container is designed specifically for high-throughput production on the latest Formlabs ecosystem. This translucent, soft-touch elastomer offers an 80A Shore durometer, making it the perfect choice for prototyping stiff, rubber-like parts that need to endure repeated bending and compression. Designed to simulate the properties of TPU or harder rubbers, this material allows engineers to produce functional prototypes in-house. Please note that this high-volume 5-liter container requires a Resin Pump for operation, ensuring a seamless and automated material supply for your Form 4 series printers.

Why Choose Flexible 80A Resin?

Industrial-Grade Elastomer

By integrating Formlabs Flexible 80A Resin Form 4, 5L into your production line, you can bypass the time-consuming and expensive processes of outsourcing or mold making. This material empowers you to create silicone, urethane, and rubber-like components directly in your workshop in a matter of hours, significantly accelerating your product development cycle.

Resilient and Pliable

Parts printed with this advanced resin exhibit excellent elastomeric properties. They are capable of bending and flexing, slowly returning to their original geometry, which is essential for components that require a balance between stiffness and flexibility.

Endurance Under Pressure

Durability is a key factor in functional testing. Objects created with this resin are both soft and strong, allowing them to withstand rigorous stretching and compression through repeated cycles without developing cracks or structural failures.

Clear Internal Visibility

The material features a translucent finish, allowing for the creation of clear objects. This transparency provides valuable visibility into the internal structure of a model, which can be crucial for fluid dynamics or checking internal fitments.

Functional Prototyping

Achieve a realistic look and feel that mimics final production parts. This durability supports extensive user testing, ensuring that your prototypes can be put through real-world scenarios before mass manufacturing begins.

Applications

Versatile Engineering Uses

The Formlabs Flexible 80A Resin Form 4, 5L is an ideal solution for creating hard yet flexible prototypes, serving as a superior alternative to traditional mold making. Its unique properties make it suitable for a wide array of industries and applications.

Recommended Use Cases

Engineers and designers frequently utilize this material for creating ergonomic handles, soft-touch grips, and overmolds that require tactile comfort. It is also excellent for manufacturing seals, gaskets, and masks that need to maintain a tight fit. Furthermore, its damping qualities make it perfect for cushioning and shock absorption components. In the medical field, it is often used to model anatomy such as cartilage, tendons, and ligaments.

Post-Processing

Cleaning the Prints

To ensure the highest quality surface finish, the foundational step in the SLA workflow involves washing the parts. Using an alcohol or ether wash effectively removes any excess uncured resin from the surface, preparing the object for the final stage.

Achieving Peak Performance

For engineering and specialty materials like the Formlabs Flexible 80A Resin Form 4, 5L, post-curing is not optional but essential. This process completes the polymerization reaction that began during printing, transforming the part from a "green" state into a fully finished component with maximized strength and mechanical functionality.

Technical Specifications

- Material Properties: Simulates durometer rubber, high impact resistance and compression, great for ergonomic soft-touch grips.

- Application: Engineering

- Print technology: SLA

- Type: Translucent

- Ultimate Tensile Strength: 8.9 MPa

- Stress at 50% Elongation: 3.1 MPa

- Stress at 100% Elongation: 6.3 MPa

- Elongation at Break: 120%

- Tear Strength: 24 kN/m

- Hardness Shore A: 80A

- Recommended lifetime/shelf life: 24 months

- PRINTERS: Form 4/4B, Form 4L/4BL

- RESIN TANKS: Form 4 Tank, Form 4L Tank

- LAYER THICKNESS (Form 4/4B): 100 microns

- LAYER THICKNESS (Form 4L/4BL): 100 microns

Buy Formlabs Flexible 80A Resin Form 4, 5L at 3DDevice

When you choose to purchase from the 3DDevice online store, you are choosing reliability and expertise. We have been leaders in the 3D printing market since 2012, offering deep industry knowledge to help you find the right solutions. As an official representative of Formlabs, we guarantee the best prices, official warranty coverage, and certified service support for all equipment and consumables. Our team provides comprehensive advice and qualified assistance in choosing the right materials, ensuring support before, during, and after your purchase.