- Stock: In Stock

- Product code: 00-00000262

- Shipping Weight: 1.50kg

- SKU: RS-F2-ELCL-01

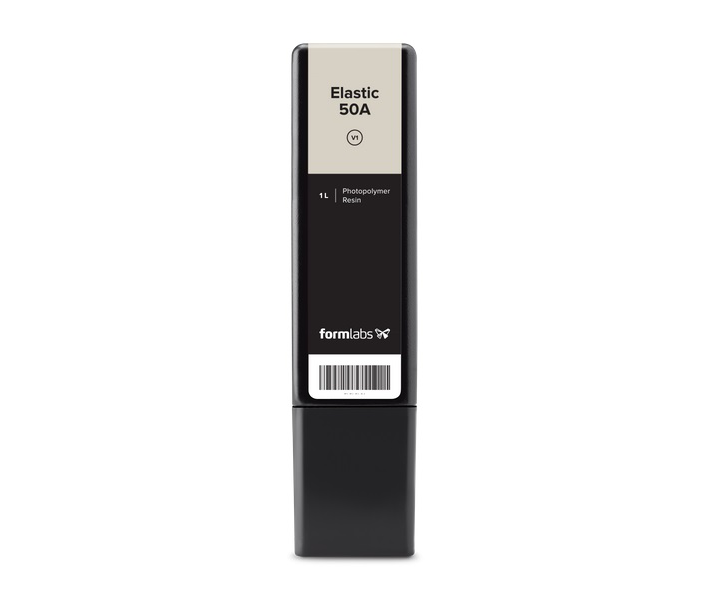

Formlabs Elastic 50A Resin Cartridge

Formlabs Elastic 50A Resin is the softest engineering polymer in the range of flexible photopolymers from the manufacturer Formlabs with a Shore hardness of 50A. It is suitable for prototyping soft and flexible parts, usually made from silicone. Parts printed from this material look and behave like molded silicone parts and are durable enough for use over many cycles.

Applications of Elastic 50A Resin

This is an excellent choice for printing 3D models that will be repeatedly bent, stretched, and compressed, and quickly return to their original shape. Elastic 50A will withstand all these deformations with dignity without tearing over a long period of time.

Elastic 50A resin is an elastic material designed for use in resilient and highly stretchable products. It is designed to "bounce back" and quickly return to its original shape. It is very well suited for creating medical models, for modeling or training, because it is flexible and transparent.

In application areas such as production process optimization, rapid project iteration, or evaluation of shape, fit, and functionality, the Formlabs Elastic 50A engineering photopolymer withstands significant testing and operates under stress conditions.

Ideal for creating

- consumer product prototypes

- flexible robotics elements

- medical devices, anatomical prostheses

- film and theater props.

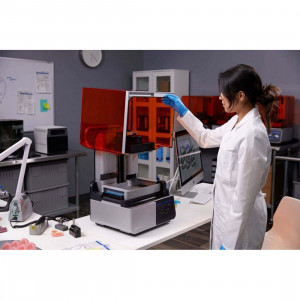

Typically, soft silicone parts used for wearable products, medical models, robotics, and special fixtures are made using mold-making or outsourcing technologies. The production of high-quality elastic materials was once only possible on expensive industrial equipment. Now, with affordable industrial-quality 3D printers like the Form 3, it has become possible to produce elastic parts on a desktop in just a few hours.

Developing resins for soft stereolithography (SLA) can be a challenging task. Parts must be highly elastic but strong enough not to tear during printing – two properties that are usually diametrically opposed.

Elastic resin for direct printing of soft flexible prototypes and models. Replacement for expensive and lengthy injection molding: