- Stock: In Stock

- Product code: 00-00013546

- Shipping Weight: 1.50kg

- SKU: RS-F2-DLCO-01

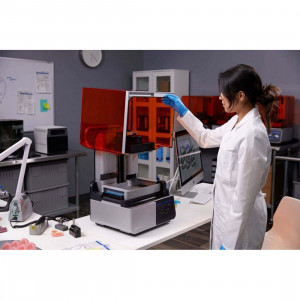

Transform your digital dentistry workflow with Formlabs Dental LT Comfort Resin Form 3 Cartridge, 1L, 1.1 kg. Engineered specifically for the Form 3 series printers, this long-term biocompatible material enables the direct production of flexible occlusal splints and night guards with exceptional ease. By combining durability with a comfortable, flexible fit, this resin produces high-quality appliances that polish to high optical transparency, significantly improving patient satisfaction and adherence to treatment plans.

A Superior Material for Long-Term Appliances

Enhanced Flexibility for Comfort

Create splints that patients will actually want to wear. Dental LT Comfort Resin is formulated to be flexible, providing a more forgiving and comfortable fit compared to rigid materials. This added comfort is key to boosting patient adoption and ensuring consistent compliance with long-term therapy.

Crystal-Clear Aesthetics

Achieve impressive optical clarity with minimal effort. Printed appliances feature a high degree of transparency right out of the printer and can be easily polished to a glass-like finish. This reduces manual labor time while delivering a premium, nearly invisible aesthetic that patients prefer.

High Impact and Wear Resistance

Manufacture appliances that are built to endure. Designed to withstand the rigors of bruxism and daily wear, this resin offers excellent resistance to impact and abrasion. It ensures that night guards and splints maintain their integrity even in demanding therapeutic situations.

Certified Biocompatibility

Deliver clinical treatments with total confidence. Dental LT Comfort Resin is a strictly tested, biocompatible material safe for long-term intraoral use. It provides both clinicians and patients with the peace of mind necessary for effective dental care.

Primary Applications

Dental LT Comfort Resin is the ideal choice for fabricating comfortable, flexible, and durable dental appliances, including:

- Flexible Occlusal Splints

- Protective Night Guards

- Custom Bleaching Trays

Workflow Guide: 3D Printing Occlusal Splints

Follow this validated workflow to produce high-quality splints using your Formlabs Form 3 series printer.

Step 1: Scan and Design

Begin by collecting a digital impression of the patient’s dentition using an intraoral scanner or a desktop scanner for physical models. Import the scan data into your dental CAD software to design the splint. Ensure the design has a minimum thickness of 2.0 mm for occlusal surfaces and 1.5 mm for walls to guarantee durability. Export the final design as an STL file.

Step 2: Print on Form 3

Import the STL file into PreForm. Select "Dental LT Comfort" from the material menu and choose a 100-micron layer height. Orient the splint with the occlusal surface angled away from the build platform (typically 10–30 degrees) to ensure the best fit and minimize support marks on critical areas. Send the job to your Form 3 or Form 3B printer.

Step 3: Wash and Cure

Wash the printed parts in a Form Wash using isopropyl alcohol (IPA, ≥96%) for 5 minutes. Do not exceed this time to maintain dimensional accuracy. Allow parts to air dry completely (at least 30 minutes). Once dry, place them in a Form Cure and post-cure at 60 °C for 60 minutes to achieve full biocompatibility and mechanical strength.

Step 4: Finish and Polish

Remove the support structures carefully using a cutting disc or snips. Smooth any support marks with a bur. To achieve high optical transparency, use a polishing wheel and pumice for pre-polishing, followed by a high-shine polishing compound on a rag wheel. The result is a clear, smooth, and comfortable appliance ready for delivery.

Material Properties

- Application: Dental

- Printing Technology: SLA

- Material Type: Flexible

- Ultimate Tensile Strength: 29.1 MPa

- Tensile Modulus: 994 MPa

- Elongation: 33%

- Flexural Strength: 21 MPa

- Flexural Modulus: 643 MPa

- Notched Izod Impact: 98 J/m

- Hardness Shore D: 75D

Your Official Formlabs Partner

As an official representative of Formlabs, 3DDevice guarantees the best price, an official warranty, and professional service support. Our experts, with experience since 2012, are here to provide advice and assist you in making the right choice. Rely on us for qualified support before, during, and after your purchase to ensure you achieve the best possible results with your 3D printing projects.