- Stock: In Stock

- Product code: 00-00013530

- Shipping Weight: 1.50kg

- SKU: RS-C2-CWPU-01

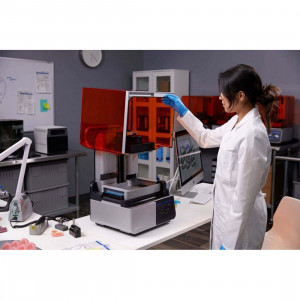

Achieve flawless castings with unparalleled detail using Formlabs Castable Wax Resin Form 4 Cartridge, 1L. This 20% wax-filled material is engineered for reliable investment casting, providing zero ash content and a clean burnout every time. It excels at capturing the most intricate features and produces an exceptionally smooth surface finish, making it the premier choice for creating ultrafine jewelry and highly accurate patterns for casting and pressing dental prosthetics.

The Professional's Choice for Casting Patterns

For Delicate and Intricate Jewelry

Castable Wax Resin offers the high strength and stiffness required to print the most delicate and complex jewelry designs. Its excellent green strength ensures that ultrafine structures, such as wire filigree and micropavé settings, retain their perfect shape from print to cast. For heavier jewelry pieces, we recommend using Castable Wax 40 Resin.

For High-Accuracy Dental Prosthetics

This resin is the go-to material for dental labs and technicians who demand precision. It produces highly accurate, dimensionally stable patterns for casting or pressing copings, substructures, full contour crowns, and removable partial denture (RPD) frameworks, seamlessly integrating into your digital dentistry workflow.

Dental Casting and Pressing Workflow Guide

Follow this validated workflow to produce high-quality cast or pressed dental restorations using 3D printed patterns.

Step 1: Scan and Design

Begin by capturing the patient's anatomy with an intraoral or desktop scanner. Using your preferred dental CAD software (e.g., 3Shape, exocad), design the restoration. Ensure minimum thickness for copings is 0.4–0.5 mm and for RPD connectors is 1.0–1.2 mm. Export the final design as an STL or OBJ file.

Step 2: Print

Import the file into PreForm software. Select "Castable Wax" as the material and a 50-micron layer height. Orient parts with critical surfaces angled away from the build platform to minimize support marks. After setup, shake the resin cartridge and send the job to the printer. Use a dedicated resin tank for casting resins to prevent contamination.

Step 3: Wash and Post-Cure

Wash the printed pattern in isopropyl alcohol (IPA, ≥99%) for 10 minutes using a Form Wash. Allow the part to air dry completely for at least 30 minutes. Once dry, post-cure the part in a Form Cure at 60 °C for 30 minutes. Post-curing is critical for achieving the necessary strength for handling and ensuring a clean burnout.

Step 4: Sprue, Invest, and Burnout

After removing supports, sprue the pattern as you would a traditional wax pattern. Use a high-quality, fine-grained phosphate-bonded investment material. Follow a slow-ramp burnout schedule to ensure the resin burns out cleanly without damaging the investment:

- Ramp 1: From room temperature, heat at 3 °C/minute to 288 °C. Hold for 180 minutes.

- Ramp 2: Heat at 3 °C/minute to 593 °C. Hold for 180 minutes.

- Ramp 3: Heat at 4 °C/minute to the final casting temperature (e.g., 871 °C). Hold for 60 minutes before casting.

Step 5: Cast or Press

Once the burnout cycle is complete, the investment mold is ready. Proceed with your standard casting or pressing procedures using your chosen alloy or ceramic material. After casting/pressing, allow the mold to cool, then devest and finish the restoration using your standard techniques.

System Compatibility

- Printer compatibility: Form 4, Form 4B, Form 4L, Form 4BL, Form 3, Form 3L, Form 3B, Form 3BL, Form 2

- Compatible resin tanks: Form 2 Resin Tank (PDMS), Form 2 LT Tank, Form 3 Resin Tank V2.1, Form 3L Resin Tank V3, Form 4 Resin Tank, Form 4L Resin Tank

- Compatible build platforms: Form 4 Build Platform, Form 4 Flex Build Platform, Form 3 Build Platform, Form 3 Build Platform 2, Form 3 Stainless Steel Build Platform, Form 3L Build Platform, Form 3L Build Platform 2L, Form 4L Build Platform, Form 4L Flex Build Platform

Your Official Formlabs Partner

As an official representative of Formlabs, 3DDevice guarantees the best price, an official warranty, and professional service support. Our experts, with experience since 2012, are here to provide advice and assist you in making the right choice. Rely on us for qualified support before, during, and after your purchase to ensure you achieve the best possible results with your 3D printing projects.