- Stock: In Stock

- Product code: 00-00013522

- Shipping Weight: 1.50kg

- SKU: RS-C2-BMWH-01

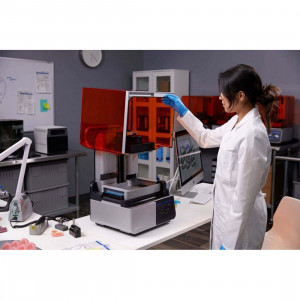

Produce high-quality, patient-safe medical devices with Formlabs BioMed White Resin Form 4 cartridge, 1L. This rigid, opaque white material is engineered for biocompatible applications where aesthetics, high definition, and certified safety are essential. Manufactured in an FDA-registered, ISO 13485 facility and holding a USP Class VI certification, BioMed White Resin is a trusted solution for creating robust, sterilizable end-use parts for medical, pharmaceutical, and consumer healthcare applications.

Print with USP Class VI Certified Performance

Manufactured to Medical-Grade Standards

Rely on a material that meets stringent quality requirements for healthcare. BioMed White Resin is produced in strict adherence to ISO 13485, ensuring that every cartridge delivers the lot-to-lot consistency, traceability, and reliability needed for critical applications.

USP Class VI Certified for Advanced Use

Meeting one of the highest standards for biocompatibility, this resin's USP Class VI certification makes it suitable for pharmaceutical and drug delivery device development, where low toxicity and material safety are non-negotiable.

Opaque White for High-Contrast Visualization

The bright, opaque white finish provides excellent visual contrast, making it the perfect choice for anatomical models that require clear visualization of details. It is also ideal for creating surgical guides and templates where markings and guides need to be easily visible in a clinical setting.

Validated for Patient Safety

BioMed White Resin is certified for long-term skin contact (>30 days) and short-term contact with bone, tissue, dentin, and mucosal membranes (<24 hours). Printed parts are fully compatible with common sterilization methods, making them safe for a wide variety of patient-contact scenarios.

Ideal Applications for Medical and Pharmaceutical Use

With its unique combination of an opaque white finish and extensive safety certifications, BioMed White Resin is perfectly suited for a wide range of uses:

- End-use medical device components and housings.

- Patient-specific cutting and drilling guides for surgical accuracy.

- Detailed anatomical models for pre-surgical planning and education.

- Molds and sizing models for patient-specific implants.

- Biocompatible jigs, fixtures, and surgical tools for the operating room.

*The final device manufacturer is responsible for validating the biocompatibility and performance of all printed parts for their specific application and use. Formlabs provides extensive biocompatibility and sterilization data to support this process.

Material Properties

- Ultimate Tensile Strength: 45.78 MPa

- Tensile Modulus: 2020.16 MPa

- Elongation: 10%

- Flexural Strength: 74.46 MPa

- Flexural Modulus: 2020.16 MPa

- Hardness Shore D: 80 D

- Notched Izod: 15.11 J/m

- Heat Deflection Temp @ 0.45 MPa: 67 ºC

Essential Post-Processing for Certified Biocompatibility

To unlock the material's certified biocompatibility and achieve its final mechanical properties, a complete and precise post-processing workflow is mandatory. This includes washing away all residual resin and post-curing the parts according to the official instructions for use. Please consult the manufacturing guide for detailed protocols.

Your Official Formlabs Partner

As an official representative of Formlabs, 3DDevice guarantees the best price, an official warranty, and professional service support. Our experts, with experience since 2012, are here to provide advice and assist you in making the right choice. Rely on us for qualified support before, during, and after your purchase to ensure you achieve the best possible results with your 3D printing projects.