- Stock: In Stock

- Product code: 00-00013588

- Shipping Weight: 5.50kg

- SKU: RS-RPS-BMEL-01

Formlabs BioMed Elastic 50A Resin, 5L: Advanced Biocompatible Material

Unlock new possibilities in medical manufacturing with the Formlabs BioMed Elastic 50A Resin, 5L. This large-format container is designed for high-volume production of soft, biocompatible parts that require flexibility and transparency. Whether you are creating patient-specific devices or complex anatomical models, this resin ensures comfort and safety, backed by rigorous ISO certifications. Please note that this 5L container requires a Resin Pump for operation, ensuring a seamless workflow for high-throughput printing.

Why Choose BioMed Elastic 50A Resin?

Innovation in Healthcare

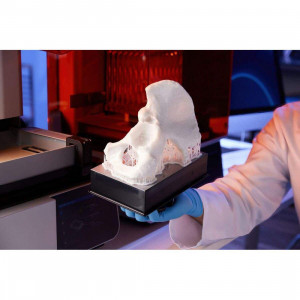

Accelerate medical innovation by integrating 3D printing into your workflow with BioMed Elastic 50A Resin. This material bridges the gap between digital design and physical application, allowing for the creation of comfortable, patient-specific medical devices. It is also an excellent choice for fabricating soft tissue models that surgeons can use for pre-operative planning and reference directly in the operating room (O.R.).

Comfortable

Patient-Centric Design

Create mass-customized, medical-grade components that prioritize patient well-being. The material's inherent properties ensure that the final parts are not only functional but also exceptionally comfortable to wear, making them ideal for devices that require prolonged contact with the body.

Soft

Realistic Tissue Simulation

Achieve a tactile feel remarkably similar to human soft tissue. This resin delivers authentic biomechanical behaviors, making it the perfect solution for printing full-sized heart models, gastrointestinal structures, or intricate neurovascular systems. These realistic models provide surgeons with invaluable haptic feedback before stepping into the O.R.

Transparent

Optical Clarity

Clarity is crucial for visualization in medical applications. Parts manufactured with this material offer excellent transparency, allowing medical professionals to clearly observe internal structures and monitor how fluids or tools move within the printed object.

Medical-Grade Material, Biocompatible Parts

Certified Safety Standards

Reliability is paramount in medicine. Formlabs BioMed Elastic 50A Resin is produced within a strict Quality Management System adhering to ISO 13485 standards. You can print with confidence knowing the material meets USP Class VI requirements and is suitable for long-term skin contact (over 30 days) and short-term mucosal membrane contact (under 24 hours).

Applications

Versatile Medical Use

Streamline your production by directly 3D printing soft, elastic parts that require certified biocompatibility. By eliminating the need for expensive and time-consuming molding processes, you can rapidly produce comfortable medical devices and anatomical models. It is particularly well-suited for devices needing extended skin contact and soft tissue simulation for organs, muscles, and vasculature.

Post-Processing

Ensuring Optimal Performance

To achieve the required safety standards and mechanical properties, proper post-processing is essential. The workflow begins with washing parts in isopropyl alcohol to remove excess resin. For biocompatible applications, post-curing is mandatory to meet regulatory safety standards. Always refer to the official manufacturing guide to ensure compliance and safety.

Using BioMed Elastic 50A Resin

Workflow and Compatibility

This soft, medical-grade material is designed for applications demanding comfort, transparency, and strict biocompatibility. Manufactured in an FDA-registered facility, it complies with ISO 10993 and USP Class VI standards. The resin prints at 100 microns and is compatible with specific Formlabs SLA printers.

Printing with BioMed Elastic 50A Resin

Seamless Print Setup

Setting up a print job is straightforward using the PreForm software. Simply open your model, select the specific resin and layer thickness, and orient the part to preserve fine details. Once supports are generated, the job is ready to be sent to your compatible Formlabs printer.

Finishing and Post-Curing Requirements

Finalizing the Part

Use the Form Wash to clean parts in 99% IPA, ensuring any internal channels in hollow models are thoroughly flushed. A critical step for BioMed Elastic 50A Resin is the post-curing process: parts must be fully submerged in a glass container of water (at least 500mL) during the cure cycle to eliminate surface tackiness and ensure full biocompatibility. Improper curing can result in suboptimal mechanical properties.

Technical Characteristics

- Material Name: BioMed Elastic 50A Resin

- Container Volume: 5L (Requires Resin Pump)

- Application: Medical

- Printing Technology: SLA

- Type: Elastomeric

- Ultimate Tensile Strength: 2.3 MPa

- Stress at 50% Elongation: 1 MPa

- Stress at 100% Elongation: 1.3 MPa

- Elongation: 150%

- Tear Strength: 11 kN/m

- Hardness: 50A Shore A

- Recommended Lifetime: 24 months

- Compatible Printers: Form 3B, Form 3BL, Form 4B, Form 4BL

- Compatible Resin Tanks: Form 3 Tank (all), Form 3L Tank (all), Form 4 Tank, Form 4L Tank

- Layer Thickness: 100 microns (Form 3B/3BL/4B/4BL)

Buy Formlabs BioMed Elastic 50A Resin at 3DDevice

Purchase the Formlabs BioMed Elastic 50A Resin, 5L from the experts at 3DDevice. We have been operating in the additive manufacturing market since 2012, providing not just products, but comprehensive solutions. Our team offers professional advice to help you choose the right materials and assists you at every stage—from selection to post-purchase support.

As an official representative of Formlabs, we guarantee the best prices on the market, official warranty service, and qualified technical support. Trust your medical production to authorized experts who understand the nuances of biocompatible 3D printing.