- Stock: In Stock

- Product code: 00-00013584

- Shipping Weight: 5.50kg

- SKU: RS-RPS-BMBL-01

Take your medical manufacturing to the next level with the Formlabs BioMed Black Resin, 5L container. Designed for high-volume production, this specialized material offers a sophisticated matte black finish combined with the rigidity and extensive biocompatibility certifications necessary for critical healthcare applications. Whether you are prototyping or producing end-use parts, this resin ensures both aesthetic appeal and patient safety. Please note that this 5L container requires a Resin Pump for operation, and items with delivery times exceeding 5 weeks are made to order.

Certified for Demanding Medical Applications with Formlabs BioMed Black Resin, 5L

Uncompromising Safety Standards

Print with absolute confidence knowing you are using a material produced under the most rigorous quality controls. Formlabs BioMed Black Resin, 5L is manufactured in an FDA-registered facility that strictly adheres to ISO 13485 standards. This compliance guarantees the lot-to-lot consistency, full traceability, and reliability that are non-negotiable in the medical industry.

USP Class VI Compliance

Meeting some of the toughest testing standards for biocompatibility, this resin is USP Class VI certified. This designation makes it an exceptional choice for pharmaceutical and drug delivery applications where low toxicity and material safety are paramount concerns.

Optimized for Visual Clarity and Aesthetics

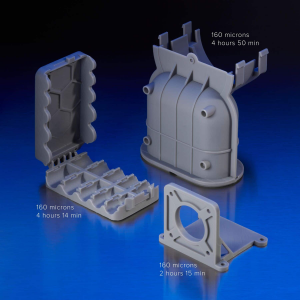

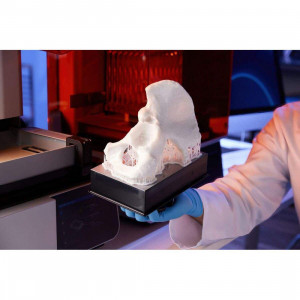

Superior Definition and Contrast

The rich, matte black finish of this material provides excellent visual contrast, which is essential for highlighting intricate anatomical details on models or creating distinct components within complex assemblies. Its non-reflective surface significantly reduces glare, making it perfectly suited for use in brightly lit surgical suites or clinical environments where visibility is critical.

Validated for Patient Contact

Versatile Clinical Use

Formlabs BioMed Black Resin, 5L is fully certified for long-term skin contact (exceeding 30 days) and short-term mucosal membrane contact (up to 24 hours). Furthermore, parts printed with this material can be sterilized using common industry methods, ensuring they are safe and ready for a wide variety of patient-contact applications.

Key Applications in Healthcare and Beyond

Diverse Manufacturing Possibilities

With its unique blend of professional aesthetics and certified safety, this resin is ideal for numerous uses. It serves as an excellent material for creating sleek end-use medical devices, biocompatible molds, and jigs for medical manufacturing. It is also perfect for high-quality consumer goods, such as wearables, that require skin-safe properties. While Formlabs provides extensive data, the final device manufacturer is responsible for validating the performance for specific applications.

Mandatory Post-Processing for Biocompatibility

Essential Finishing Protocols

To achieve the certified biocompatibility and optimal mechanical properties of the material, a precise post-processing workflow is mandatory. This involves thoroughly washing away all residual resin and post-curing the parts according to the official instructions for use. Adhering to these guidelines is crucial for ensuring the safety and performance of the final product.

Technical Characteristics

- Ultimate Tensile Strength: 35.71 MPa

- Tensile Modulus: 1523.74 MPa

- Elongation: 14%

- Flexural Strength: 57.16 MPa

- Flexural Modulus: 1668.53 MPa

- Hardness Shore D: 77 D

- Notched Izod: 24.77 J/m

- Heat Deflection Temp @ 0.45 MPa: 67.9 ºC

Purchase the Formlabs BioMed Black Resin, 5L at 3DDevice to ensure you receive genuine products and superior service. As an official representative of Formlabs, we guarantee the best price, official warranty, and comprehensive service support. Our team of experts, with experience dating back to 2012, is ready to provide advice and assistance in choosing the right materials. We offer qualified support before, during, and after your purchase to help you succeed in your 3D printing projects.