- Stock: In Stock

- Product code: 00-00000255

- Shipping Weight: 5.50kg

- SKU: RS-F2-AL4N-01

Buy Formlabs Alumina 4N Ceramic Printing Resin

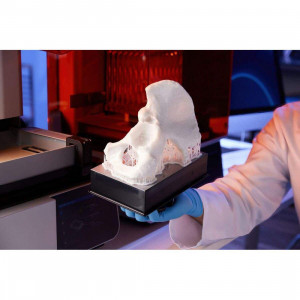

At the 3DDevice store, you can buy Alumina 4N Resin – a new material from Formlabs, which has made the most affordable 3D printing of technical ceramic products possible.

Formlabs Alumina 4N Resin is a high-density and high-purity technical ceramic material for precise 3D printing of exceptionally efficient parts that will operate in extreme conditions*.

*The material requires a firing stage and is true ceramic.

Advantages of 3D Printing with Ceramic Resin

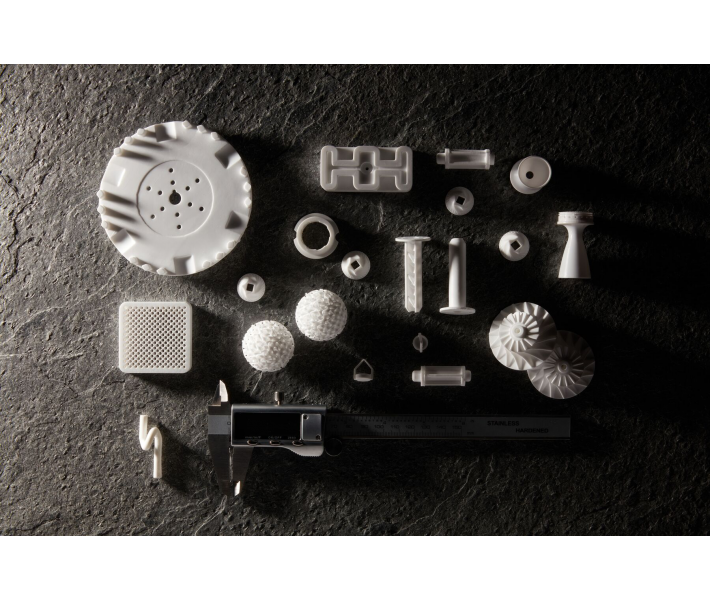

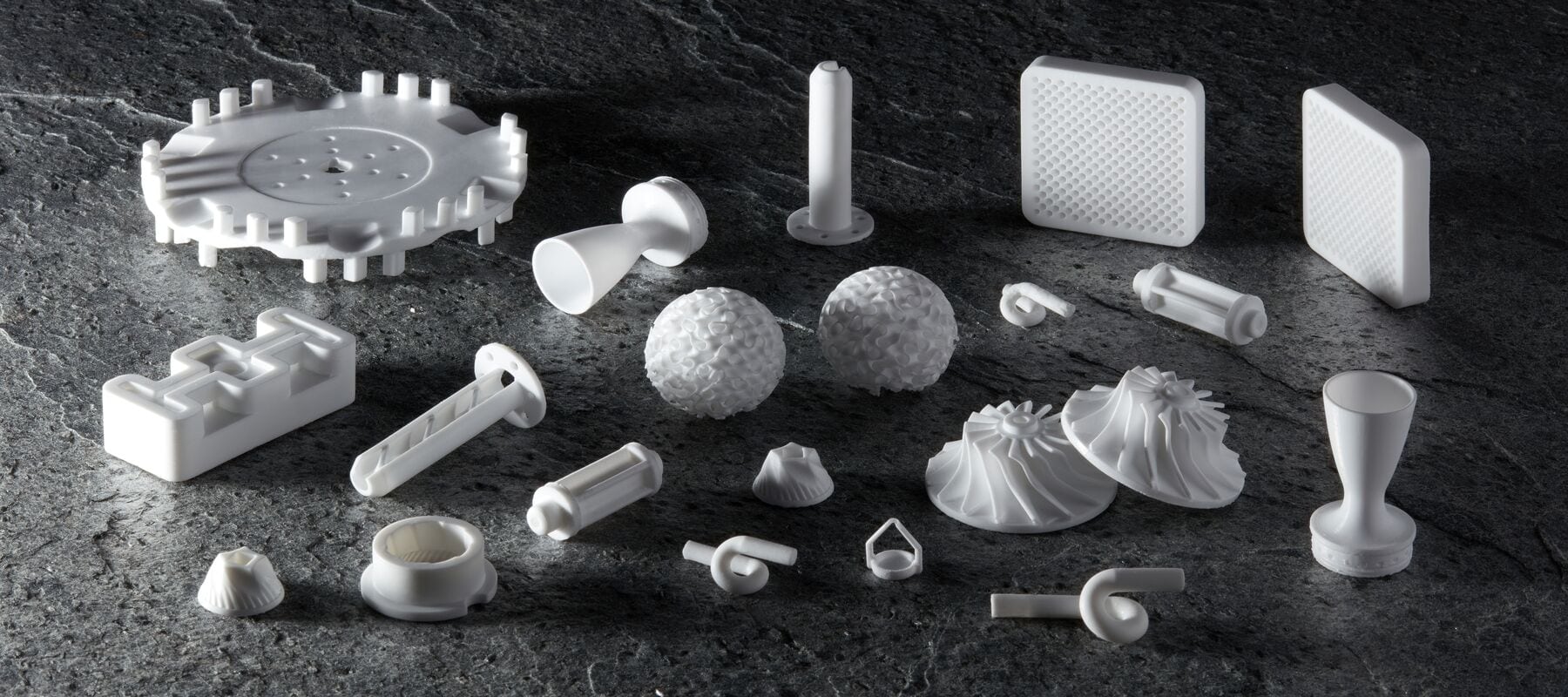

This is a heat-resistant, hard, abrasion-resistant, mechanically strong, and chemically inert material that opens up new accessible geometrically complex parts for your production, chemical laboratory, workshop, or foundry.

Abandon expensive tools and molds for geometric freedom, reduced production costs, and a faster end-to-end process and overall development cycle.

- Maintains flexural strength of 400 GPa

- Maximum operating temperature 1500 °C

- Hardness HV10 1370

- Young's modulus 380 GPa

- Purity 99.99% and relative density 98.6%

A New Era of Affordable Technical Ceramics

Alumina 4N resin is designed to meet the technical needs of the high-end engineering market.

All materials included are specifically designed to work with the resin everywhere, from printing to processing, burnout, and final properties. The ecosystem and technology create new extraordinary performance of aluminum oxide parts with design freedom and 3D printing execution time at one-tenth the initial cost of leading alternatives.

Many industries rely on technical ceramics for high thermal resistance, electrical resistance, abrasion, and chemical resistance. The limitations here are the cost and duration of traditional production, which, in turn, has less design freedom than 3D printing. Existing ceramic 3D printers cost hundreds of thousands of dollars and require specialized operators. With Alumina 4N Resin, anyone can use ceramic 3D printing and abandon expensive tools and molds for design freedom, reduced production costs, and faster execution times. Thanks to the Formlabs SLA ecosystem, previously impossible ceramic projects are now available to everyone.

Applications

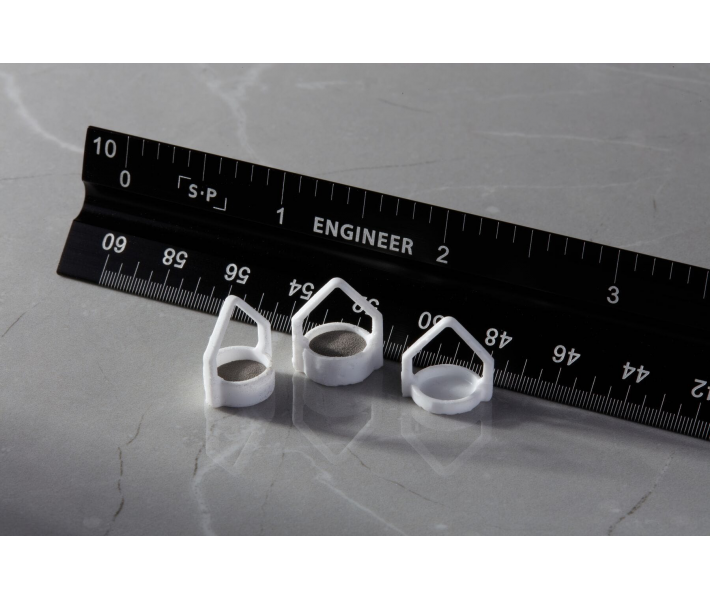

Alumina 4N Resin easily integrates into your workflows for producing affordable parts with complex geometry and low entry barriers. 3D printing of ceramic components with complex internal channels, lattice structures, and complex geometry that are impossible with traditional alumina. The material prints extremely efficient products with exceptional thermal, mechanical, and electrical properties comparable to traditionally manufactured alumina.

- High-voltage components: housings, connector housings and covers, terminal blocks.

- Chemically resistant components: collector pipes, mixing blades, pipes.

- Thermally resistant components: spark plug insulators, electrical mounting, insulating housings or tubes.

- Foundry tools for metal casting: cores, crucibles, mixing tools, thermocouple shells, metal filters.

Washing Printed Parts with Alumina 4N

Important: Do not allow parts made from Alumina 4N resin to come into contact with water or IPA, as this will cause cracking. Wash printed products made from Alumina 4N material only with the Formlabs Ceramic Wash Solution.

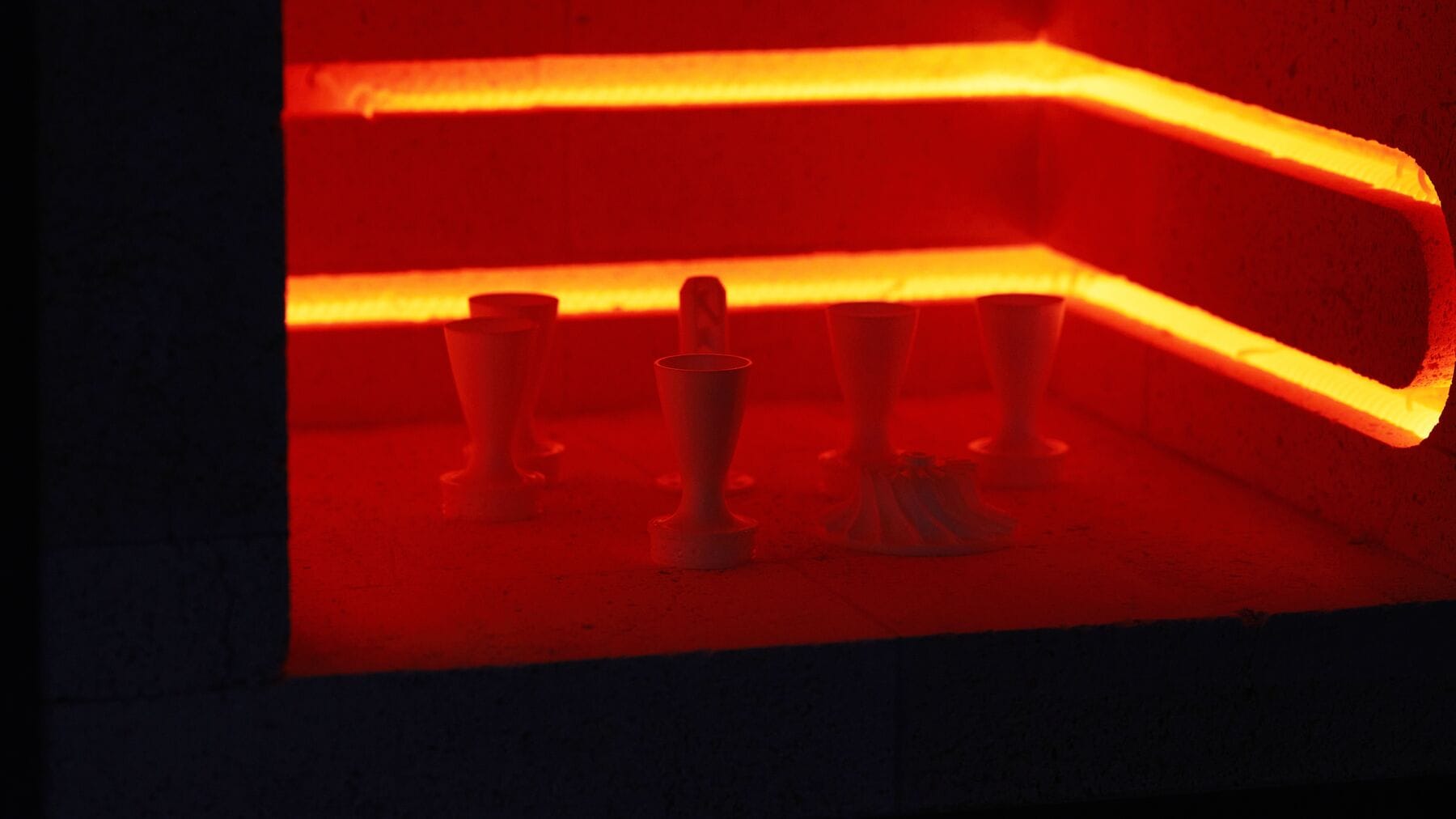

Firing Process for Alumina 4N Photopolymer Parts

The firing process for parts includes two stages: burnout and sintering. The burnout stage is designed to slowly burn out all the polymer material in the printed parts, which includes all the photo-curable material. This process is quite slow, taking a couple of days at temperatures from approximately 150 °C to 600 °C, so that all the material slowly releases gas without creating excessive pressure.

This usually occurs in a separate furnace, as we will have a bit more control/they are more common, and then we raise the temperature to 1000 °C to achieve very light pre-sintering. The actual sintering process is the transition from a loosely bonded set of powder to a fully consolidated dense part, and it can take significantly less time, with the main constraint being the time for complete and uniform heating of the ceramic.

Storage of Alumina 4N Resin Cartridge

Refrigeration is recommended for long-term storage and can extend the shelf life to 12 months (room temperature – 3 months). Cooling will not affect its properties if the material is warmed to room temperature. It is recommended to quickly shake the cartridge (5-10 seconds) during the first use, as well as after it has not been used for more than a month. If the material is stored in the tank for more than a month, it may be necessary to gently stir it manually using a non-damaging tool to reincorporate any settled material.

Specifications

| Printing Technology | SLA |

| Polymerization | Required |

| Burnout and Firing | Required |

| Flexural Strength | 400 MPa |

| Purity, % | 99.99% |

| Relative Density | 98.6% |

| CTE (Coefficient of Thermal Expansion) | 5 ppm/K |

| Maximum Operating Temperature | 1500 ºC |

| Layer Height (microns) | Form 3/3+/3B/3B+ – 50 |

| Printer Compatibility | Form 3/3+, Form 3B/3B+ |

| Resin Tank Compatibility | Form 3/3B Resin Tank V2.1 |

| Build Platform Compatibility | Form 3 Stainless Steel Build Platform |

| Volume (L) | 0.78 |

| Country of Manufacture | USA |