- Stock: In Stock

- Product code: 00-00013518

- Shipping Weight: 2.50kg

- SKU: RS-C2-AL4N-01

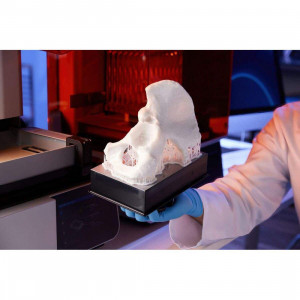

Step into the future of technical ceramics with Formlabs Alumina 4N Resin Cartridge (Form 4), 2 kg (0.78 l). This revolutionary material makes in-house ceramic 3D printing more accessible and affordable than ever before. As a Form X material designed for expert users, Alumina 4N Resin allows you to manufacture fully dense, high-purity (99.99%) alumina parts without the exorbitant costs and long lead times of traditional manufacturing. Create components with unparalleled geometric freedom that deliver exceptional performance in the most extreme thermal, mechanical, and chemical environments.

Important Storage Information: Alumina 4N Resin has a shelf life of 3 months at room temperature. To extend this by up to 12 additional months, we strongly recommend refrigerating the resin at -10 to 4 °C.

Why Choose Alumina 4N Resin?

Alumina 4N Resin produces parts with a 98.6% relative density and properties comparable to traditionally manufactured alumina (Al2O3), making it a game-changer for advanced engineering and manufacturing.

Make Ceramic 3D Printing Accessible

With a starting price over 10 times lower than the leading alternatives, the Formlabs ceramic ecosystem breaks down the cost barrier to producing high-performance technical ceramics. Bring your production in-house and take full control of your workflow.

Achieve Unprecedented Design Freedom

Fabricate ceramic parts with complex internal channels, intricate lattices, and advanced geometries that are simply impossible to create with traditional methods. Optimize your designs for performance without being limited by the constraints of molding or machining.

Accelerate Timelines and Reduce Costs

Eliminate the need for expensive tooling and molds. By 3D printing your ceramic parts directly, you can dramatically shorten development cycles, reduce production costs, and iterate on designs faster than ever before.

Engineered for Extreme Performance

Create parts that are reliable in the most demanding applications. With a maximum working temperature of 1500°C, a flexural strength over 400 MPa, and a modulus of 380 GPa, your components will resist heat, compression, and deflection with outstanding stability.

Applications for High-Performance Ceramics

Alumina 4N Resin is a cost-effective solution for manufacturing parts for extreme environments. Its properties as a heat and electrical insulator, combined with its chemical and wear resistance, make it ideal for industries like manufacturing, aerospace, defense, and automotive. Key applications include:

- High Voltage Components: Insulating enclosures, connector housings, terminal blocks.

- Chemical and Wear Resistance: Mixing blades, manifold pipes, wear-resistant tooling.

- Thermal Protection: Spark plug insulators, insulating tubes, electrical mounting fixtures.

- Foundry and Casting Tools: Crucibles, cores, thermocouple sheaths, and metal filters.

Material Properties

- Flexural Strength: >400 MPa

- Purity: 99.99%

- Relative Density: 98.6%

- Coefficient of Thermal Expansion (CTE): 5 ppm/K

- Maximum Working Temperature: 1500°C

Alumina 4N Resin Workflow Guide

As a Form X material, Alumina 4N Resin requires an advanced, multi-step workflow. Follow this guide for successful part creation.

Step 1: Design

Account for shrinkage during the debinding and sintering process. Scale your model in PreForm by 121.5% in the X and Y axes, and 126.5% in the Z axis. Ensure all features are within the supported wall thickness and dimension guidelines.

Step 2: Print

Shake the resin cartridge for at least one minute before inserting it. Ensure the mixer, build platform, and resin tank are clean. Send your scaled model to the printer and start the print.

Step 3: Wash

Wash printed parts in the Form Wash using >99% Isopropyl Alcohol (IPA) for a total of 20 minutes (two cycles of 10 minutes each, with fresh solvent in the second cycle). Use the included removal tool to carefully remove parts from the build platform between cycles.

Step 4: Dry

Ensure parts are completely dry before the debind and sinter stage. Use a compressed air source to blow excess IPA from part surfaces and internal channels. Allow parts to air dry for at least 30 minutes. Visually inspect to confirm no IPA remains.

Step 5: Debind & Sinter

This critical step requires a well-ventilated furnace capable of reaching at least 1550 °C. Place parts on an alumina setter plate inside the furnace. Run the debind cycle, which slowly removes the polymer binder, followed by the sinter cycle, which heats the part to a high temperature to fuse the ceramic particles into a dense, solid object. This full cycle can take over 40 hours.

Step 6: Finishing (Optional)

After sintering, supports can be removed using pliers or a rotary tool. For a smoother surface finish, parts can be sanded or polished using diamond tools and polishing compounds.

Your Official Formlabs Partner

As an official representative of Formlabs, 3DDevice guarantees the best price, an official warranty, and professional service support. Our experts, with experience since 2012, are here to provide advice and assist you in making the right choice. Rely on us for qualified support before, during, and after your purchase to ensure you achieve the best possible results with your 3D printing projects.