- Stock: Out of stock

- Product code: 00-08800339

Rubber Plastic for 3D Printing

Flexible plastic is one of the types of consumable materials for 3D printing used in desktop 3D printers. Rubber plastic for 3D printing is characterized by high elasticity and resistance to fats and oils, making it suitable for both technical and decorative applications. However, it is not recommended to expose it to acids and solvents, under the influence of which rubber plastic decomposes. Post-processing of this material is practically not possible.

Some features worth noting include certain nuances during 3D printing with this material. Due to its flexible properties, it tends to bend and tangle when fed into the extruder. To avoid this, it is recommended to set a low 3D printing speed and not to choose a nozzle that is too small in diameter. Rubber plastic for 3D printing will be an excellent option for the production of automotive components, elements of medical products, and power tools. It is also often used in the manufacture of original cases for electronics.

Specifications

| Specific Gravity | 1.19 g/cm3 |

| Water Absorption (24 hours) | 0.22 % |

| Tensile Strength | 4 MPa |

| Tear Strength | 26 MPa |

| Tensile Modulus | 12 MPa |

| Yield Elongation | 65 % |

| Relative Elongation | 660 % |

| Hardness | 82.7 m*N |

| Shore Hardness (Scale A) | 85 |

| Impact Strength (Izod, 23 ˚C) | 4.2 kJ/m2 |

| Abrasion Resistance (mass loss, 10,000 cycles) | 0.08 g |

| Melting Temperature | 216 ˚C |

| Glass Transition Temperature | -35 ˚C |

| Heat Deflection Temperature at 0.07 MPa | 60 ˚C |

| Heat Deflection Temperature at 0.45 MPa | 44 ˚C |

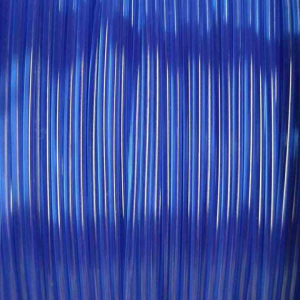

| Filament Diameter | 2.85 mm and 3 mm |

| Color | Black |

| Spool Weight | 0.8 kg |