-50 %

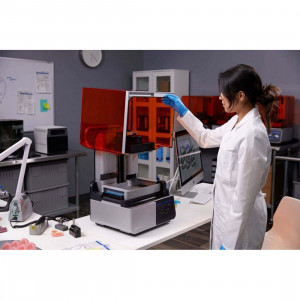

Formlabs Flexible 80A Resin for Form 4, 1L

Formlabs Authorized Partner

3DDevice is an Authorized Partner of Formlabs in Ukraine

Price Incl. VAT

- Stock: In Stock

- Product code: 00-08800067

- SKU: RS-C2-FL80-11

Based on 0 reviews.

-

Write a comment

₴5 940.00

₴11 821.00

Ex Tax: ₴5 940.00

Quantity:

Flexible 80A Resin – the flexible material for Form 4

Flexible 80A Resin for Form 4 3D prtinter is a stiff, soft-touch, translucent elastomer with a Shore hardness of 80A that is ideal for prototyping rubber-like parts with the flexibility of harder rubber or TPU.

Parts printed with Flexible 80A can withstand bending, twisting, and compression during long, repeated cycles.

Why choose Flexible 80A?

Create silicone, urethane, and rubber-like parts. Produce flexible parts in-house in hours, replacing outsourcing and molding.

- Elastomeric. Leverage for flexible parts that slowly return to shape.

- Soft and durable. Stretch and compress parts over multiple cycles without cracking.

- Transparent. Create transparent objects that allow you to see through the model.

- Robust. Support user testing by creating prototypes that look and feel like prototypes that can be tested.

Flexible 80A Resin – applications in 3D printing

Flexible 80A Resin is ideal for solid, flexible prototypes and is an excellent alternative to mold making.

- Handles, grips and overmolds.

- Seals, gaskets and masks.

- Shock absorption, cushioning and shock absorption.

- Anatomy of cartilage, tendons and ligaments.

Specifications

| Printing technology | SLA |

| Polymerization | Required |

| Ultimate Tensile Strength | 7.2 MPa |

| Stress at 50% Elongation | 2.6 GPa |

| Stress at 100% Elongation | 4.5 MPa |

| Elongation | 135% |

| Tear Strength | 22 kN/m |

| Hardness Shore A | 80А |

| Layer height (microns) | Form 4/4B – 100 |

| Printer Compatibility | Form 4/4B |

| Resin Tank Compatibility | Form 4 Resin Tank |

| Build Platform Compatibility | Form 4 Build Platform, Form 4 Build Platform Flex |

| Volume (L) | 1 |

| Manufacturer Country | USA |

If you have any questions, please contact us.

Downloads:

Technical Data Sheet, PDF (EN)

Buy Flexible 80A Resin for Form 4 3D Printer

3D Printing

Printing Technology

MSLA

Layer Height (µm)

Form 4/4B – 100

Details

Polymerization Needed

Yes

Printer Compatibility

Form 4/4B

Resin Tank Compatibility

Form 4 Resin Tank

Build Platform Compatibility

Form 4 Build Platform, Form 4 Build Platform Flex

Volume (L)

1.0

Country of Brand Registration

USA