- Stock: In Stock

- Product code: 00-08800346

- Shipping Weight: 1.20kg

PEEK plastic 3DDevice for 3D printing

PEEK plastic 3DDevice is relatively new in 3D printing, especially when working with desktop 3D printers. This is not surprising: PEEK plastic is a semi-crystalline material with a high melting point. To work with it, you will need a device with an extruder capable of heating up to at least 380˚C. Among the 3D printers presented in our online store, almost all devices in the CreatBot line have this capability. But what is so special about it?

It is an extremely durable polymer with unique physical and mechanical properties. Its main areas of application in industry are shipbuilding, aerospace and automotive industries, medicine, and electronics manufacturing. When it comes to 3D printing, 3DDevice PEEK plastic is suitable for a wide range of technical tasks, including those in the areas listed above. This material is particularly heat-resistant, chemical-resistant, and wear-resistant, making it very attractive to users.

Features of PEEK plastic

- Chemical resistance;

- Very high maximum permissible operating temperature;

- High mechanical strength and rigidity;

- Wear resistance;

- High creep resistance;

- Resistance to gamma and X-ray radiation;

- Low flammability and smoke emission when burned.

Technical characteristics

| Parameter | Standard | Value |

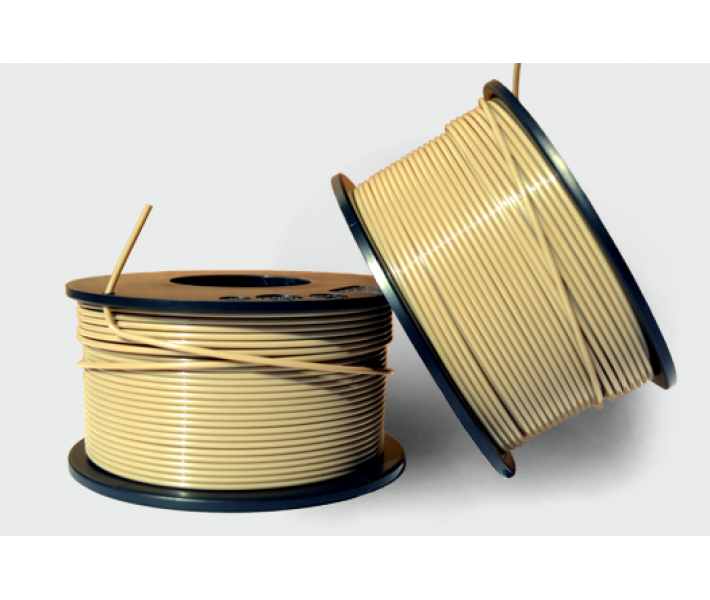

| Color | Natural or black | |

| Filament diameter | 1,75 mm | |

| Density | ISO 1183 | 1,3 ± 0,01 g/cm3 |

| Water solubility (24 hours at 25 °C) | ISO 62 | 0,5% |

| Shrinkage percentage | 3 mm, 170 °C, flow direction | 1,2% |

| Perpendicular to flow direction | 1,5% | |

| Melting point | DSC | 343 ˚С |

| Deformation temperature | ASTM D648 | 170 ˚С |

| Continuous use temperature | UL 74685 | 260 ˚С |

| Coefficient of thermal expansion | ASTM D696 | 4,7 * 10-5 ˚С |

| Strength (при 23 ° С) | ISO527-2 / 1B / 50 | 100 MPa |

| Elongation (при 23 ° С) | ISO527-2 / 1B / 50 | 34% |

| Bending strength (при 23 ° С) | ISO 178 | 163 MPa |

| Compressive strength (при 23˚С) | ASTM D695 | 118 MPa |

| Izod impact strength (Unnotched) | ISO 180 / U | No cracks |

| Rockwell Hardness | ASTM D785 | 99 |

| Flammability Level | UL 94 | 1,5 V-0 @mm |

| Dielectric Strength | IEC 248 | 1,8 kV/m |

| Діелектрична постійна | IEC 250 | 3,2 |

| Surface Resistivity | 1015 Om | |

| Friction Coefficient | 0,30-0,38 μ | |

| Reel Weight | 1 kg |