- Stock: In Stock

- Product code: 00-00013529

- Shipping Weight: 1.50kg

- SKU: RS-C2-DLCO-11

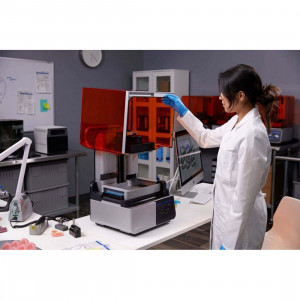

Revolutionize your dental practice with the Formlabs Dental LT Comfort Resin Form 4 cartridge, 1L 1.1kg, a premier solution for digital dentistry. This long-term biocompatible material is engineered to directly 3D print flexible occlusal splints and night guards with unprecedented ease and speed. Printed appliances are highly durable, wear-resistant, and polish to a high optical transparency, offering enhanced comfort that significantly boosts patient adoption and compliance.

Deliver Superior Comfort and Durability

Flexible for Enhanced Patient Comfort

Improve the patient experience with a flexible splint that provides a comfortable fit. This material's inherent flexibility enhances patient adoption and ensures better compliance with the prescribed treatment plan, leading to more successful outcomes.

Effortless Optical Clarity

Produce perfectly clear splints that deliver impressive optical transparency right after printing and become crystal-clear with polishing. This high-quality finish is easy to achieve, reducing the time required for manual finishing and polishing while delivering a premium aesthetic.

Built for Long-Term Wear

Deliver a robust splint that is built to last. Dental LT Comfort Resin is highly impact and wear-resistant, ensuring the appliance will withstand the rigors of bruxism and daily use in the most demanding therapeutic situations without fracturing.

Certified for Patient Safety

Provide both the patient and the clinician with the peace of mind they deserve. This resin is a certified biocompatible material, manufactured in an FDA-registered, ISO 13485 certified facility, ensuring it is safe for long-term intraoral use.

Primary Clinical Applications

Dental LT Comfort Resin allows you to offer your patients a more comfortable, flexible splint that optimizes compliance and is simpler to produce. It is the ideal material for:

- Flexible Occlusal Splints

- Comfortable Night Guards

- Custom Bleaching Trays

Material Properties

- Ultimate Tensile Strength: 29.1 MPa

- Tensile Modulus: 994 MPa

- Elongation: 33%

- Flexural Strength: 21 MPa

- Flexural Modulus: 643 MPa

- Notched Izod Impact: 98 J/m

- Hardness Shore D: 75D

Using Dental LT Comfort Resin: A Step-by-Step Guide

Follow this guide to successfully integrate Dental LT Comfort Resin into your workflow for producing high-quality, biocompatible splints.

1. Design

Using your preferred dental CAD software, design the splint or guard. For optimal results, ensure the design has a minimum thickness of 2.0 mm on the occlusal surface and 1.5 mm on the buccal and lingual walls. Once complete, export the design as an STL or OBJ file.

2. Print

Import the file into PreForm software. Select "Dental LT Comfort" as the material and a layer height of 100 microns. Orient the part with the occlusal surface angled between 10–30 degrees relative to the build platform for the best balance of accuracy and print speed. Ensure a dedicated, clean resin tank and build platform are used to maintain biocompatibility.

3. Wash

Place the printed parts in a Form Wash filled with isopropyl alcohol (IPA, ≥96%) and wash for 5 minutes. This removes any uncured resin from the surface. Do not exceed the recommended wash time as it can affect the part's dimensional accuracy.

4. Dry

After washing, remove the parts and allow them to air dry completely for at least 30 minutes. You can use compressed air to speed up the process. The parts must be fully dry and free of any tackiness before post-curing.

5. Post-Cure

Place the clean, dry parts in a Form Cure. Post-cure at 60 °C for 60 minutes. This step is mandatory to achieve the material's full mechanical properties and ensure its biocompatibility for patient safety.

6. Finishing and Polishing

First, remove the support structures using a cutting disc. To achieve high optical transparency, polish the appliance using a two-step process. Start with a rag wheel and fine pumice to pre-polish the surface. Then, use a dry rag wheel with a polishing compound to achieve a final, crystal-clear finish.

Your Official Formlabs Partner

As an official representative of Formlabs, 3DDevice guarantees the best price, an official warranty, and professional service support. Our experts, with experience since 2012, are here to provide advice and assist you in making the right choice. Rely on us for qualified support before, during, and after your purchase to ensure you achieve the best possible results with your 3D printing projects.