- Stock: In Stock

- Product code: 00-00012391

- Shipping Weight: 32.00kg

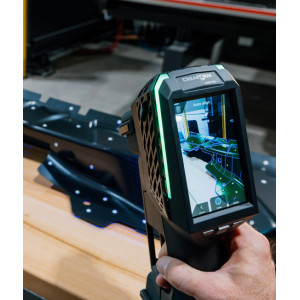

The Scanology TrackScan Sharp-E with Probe500 is a state-of-the-art hybrid 3D measurement system that combines optical scanning with high-precision probing. Designed for industries where accuracy, flexibility, and efficiency are paramount, this solution integrates advanced laser scanning with tactile measurement to deliver uncompromising results across medium and large-scale objects.

Extended Coverage and Precision

The TrackScan Sharp-E with Probe500 builds on Scanology’s TrackScan platform, optimized for parts ranging from medium components to very large structures. Equipped with a powerful 25-megapixel tracking camera and advanced optical algorithms, the system ensures stable tracking up to 6 meters. Its i-Scanner module employs 21 crossed laser lines in Ultra-fast mode, 7 parallel lines in Hyperfine mode, and a single-line laser for deep-hole inspection. This configuration delivers up to 2,600,000 measurements per second with an accuracy of ±0.025 mm.

- Scanning speed up to 2.6 million points per second.

- Accuracy up to ±0.025 mm in optical scanning.

- Probe500 tactile measurement with ±0.015 mm accuracy.

- Tracking range up to 6 m with volumetric accuracy of 0.049 mm (10.4 m³).

- Measurement volume scalable up to 49 m³ for large objects.

Hybrid Performance with Probe500

The Probe500 extends the Sharp-E system with high-accuracy tactile probing, allowing measurement of deep holes, hidden features, and critical geometries inaccessible to optical scanning. With a probing accuracy of ±0.015 mm, it complements the optical data for complete and reliable 3D inspection.

Industrial-Grade Applications

From aerospace and automotive to heavy machinery and energy sectors, the TrackScan Sharp-E with Probe500 is engineered for demanding metrological tasks. Whether capturing the geometry of an aircraft fuselage, a car body, or large castings, the system ensures precise 3D data for quality control, reverse engineering, digital archiving, and non-destructive testing.

Efficiency and Workflow Optimization

The system’s high capture speed dramatically shortens inspection cycles, while hybrid scanning with tactile probing maximizes measurement versatility. Both the tracker and scanner integrate edge-computing processors, allowing cable-free operation via Wi-Fi and USB 3.0 for ultimate portability and flexibility.

Data Output and Compatibility

The system supports multiple export formats including STL, OBJ, PLY, ASC, IGS, and TXT, ensuring compatibility with mainstream CAD/CAM and 3D design software. The ScanViewer software enables seamless integration of optical and tactile data, simplifying workflows from initial capture to final inspection reports.

Key Technical Specifications:

- Scanning Speed: up to 2,600,000 points/s

- Optical Accuracy: ±0.025 mm

- Tactile Accuracy (Probe500): ±0.015 mm

- Volumetric Accuracy: up to 0.049 mm (10.4 m³)

- Tracking Range: up to 6 m

- Measurement Volume: up to 49 m³

- Laser Modes: 21 crossed lines, 7 parallel lines, 1 single line

- Connectivity: USB 3.0, Wi-Fi

- Output Formats: STL, OBJ, PLY, ASC, IGS, TXT, etc.

Your Professional Scanning Solution

By choosing the TrackScan Sharp-E with Probe500, you gain access to one of the most advanced hybrid scanning systems on the market. Available now at 3DDevice with EU-wide delivery and professional support, it sets a new standard in high-precision 3D digitization for industrial applications.